Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Boiler Erector position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

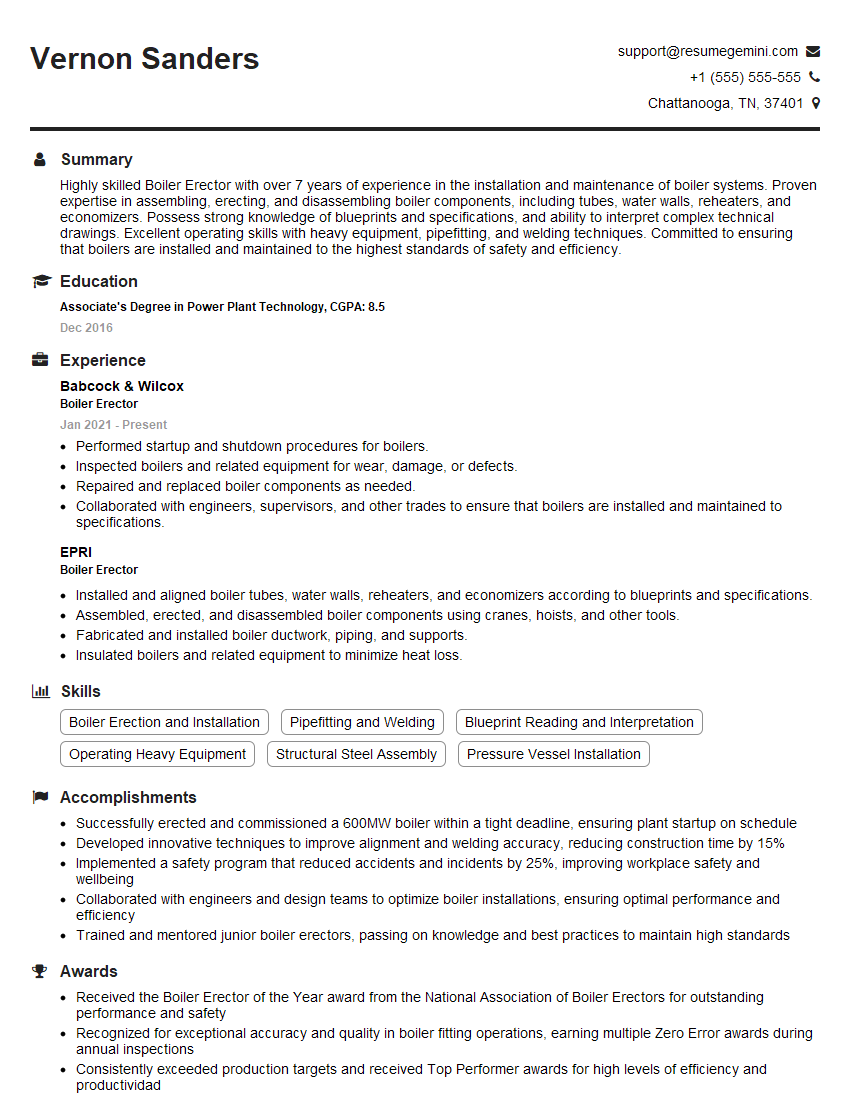

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Boiler Erector

1. How do you ensure the proper alignment of boiler components during erection?

I ensure proper alignment of boiler components during erection by:

- Using precision measuring instruments such as transit levels and theodolites to establish reference points.

- Setting up temporary supports to hold components in place.

- Measuring and adjusting the position of components as needed.

- Bolting and welding components together in a controlled manner to prevent distortion.

- Conducting regular inspections throughout the erection process to monitor alignment.

2. Explain the different types of welding techniques used in boiler erection.

- Arc Welding: Uses an electric arc to melt and join metal pieces. Includes methods like shielded metal arc welding (SMAW), gas metal arc welding (GMAW), and gas tungsten arc welding (GTAW).

- Oxyacetylene Welding: Uses a fuel gas (acetylene) and oxygen to produce a high-temperature flame for welding.

- Brazing and Soldering: Use lower temperatures than welding and are typically used to join non-ferrous metals or components that require lower joint strength.

3. How do you interpret boiler drawings and specifications?

I interpret boiler drawings and specifications by:

- Understanding the symbols, lines, and conventions used in the drawings.

- Identifying the different components and their relationships to each other.

- Reading the specifications carefully to understand the performance and safety requirements.

- Measuring and verifying dimensions against the drawings as needed.

- Consulting with engineers or supervisors if I have any questions or need clarification.

4. Describe the safety precautions you observe when working on high-pressure boilers.

- Wearing appropriate personal protective equipment (PPE) such as safety glasses, gloves, and boiler suits.

- Ensuring the boiler is properly isolated and depressurized before working on it.

- Using proper lifting and rigging techniques to move heavy components.

- Following lockout/tagout procedures to prevent accidental energy release.

- Being aware of potential hazards such as steam, heat, and electricity.

5. How do you handle and store boiler tubes properly?

- Using proper lifting techniques and equipment to avoid bending or damage.

- Storing tubes in a clean and dry environment to prevent corrosion.

- Inspecting tubes for any defects or damage before installation.

- Following manufacturer’s recommendations for handling and storage.

- Using anti-corrosion coatings or protective caps to preserve tube integrity.

6. What are the common troubleshooting techniques for boiler malfunction?

- Identifying the symptoms and potential causes of the malfunction.

- Checking instrumentation and controls for proper operation.

- Inspecting fuel supply, combustion system, and water level.

- Consulting with a boiler technician or engineer if the problem persists.

- Following safety protocols throughout the troubleshooting process.

7. Describe the process of hydrostatically testing a boiler.

- Filling the boiler with water and applying pressure to the system.

- Inspecting the boiler for any leaks or weaknesses.

- Recording the pressure and observing the behavior of the boiler under pressure.

- Adjusting and repairing any issues found during the test.

- Following safety procedures and wearing proper protective gear.

8. How do you maintain and inspect boiler safety valves?

- Regularly testing the safety valves by lifting the lever or using a test device.

- Inspecting the valve seat and sealing surfaces for wear and tear.

- Cleaning and lubricating the valve as needed.

- Adjusting the set point and blowdown rate according to manufacturer’s specifications.

- Maintaining records of safety valve inspections and tests.

9. What are the different types of boiler fuels used, and how do you handle each type safely?

- Natural gas: Requires proper ventilation and gas leak detection systems.

- Oil: Needs careful storage, handling, and combustion control to prevent fires and explosions.

- Coal: Requires proper handling and disposal of ash and dust to maintain safety and environmental compliance.

- Biomass: Involves managing fuel moisture content and preventing spontaneous combustion.

10. Explain the importance of adhering to boiler maintenance schedules and how you ensure compliance.

- Regular maintenance prevents breakdowns, extends equipment life, and ensures safety.

- I use checklists, maintenance logs, and preventive maintenance software to track tasks and ensure adherence.

- I prioritize critical tasks and coordinate with other team members to minimize downtime.

- I report any maintenance concerns or potential issues promptly to ensure timely attention.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Boiler Erector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Boiler Erector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Boiler erectors play a crucial role in the construction, installation, and maintenance of industrial boilers and related equipment. Their primary responsibilities include:

1. Boiler Assembly and Disassembly

Rigging and positioning boiler components, including drums, tubes, headers, and fittings.

- Reading and interpreting blueprints and specifications.

- Bolting, welding, and assembling boiler components according to specified procedures.

2. Equipment Installation

Installing and connecting ancillary equipment, such as pumps, fans, and piping systems.

- Ensuring proper alignment, fit, and functionality.

- Following safety protocols and industry standards.

3. Welding and Fabrication

Fabricating and repairing boiler components, including tubes, casings, and accessories.

- Utilizing welding techniques, such as MIG, TIG, and stick welding.

- Inspecting welds to ensure structural integrity.

4. Testing and Troubleshooting

Testing and troubleshooting boiler systems to identify and resolve any issues.

- Conducting hydrostatic, non-destructive, and pressure tests.

- Analyzing results and implementing appropriate corrective measures.

5. Maintenance and Repair

Maintaining and repairing boilers and associated equipment.

- Performing scheduled inspections, cleaning, and adjustments.

- Replacing worn or damaged parts and components.

Interview Tips

Preparing effectively for a boiler erector interview can increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Familiarize yourself with the company’s history, products, services, and industry trends.

- Visit the company website and social media pages.

- Read industry publications and articles.

2. Practice Answering Common Interview Questions

Prepare for questions about your skills, experience, and why you’re interested in the role.

- Review job descriptions and identify key qualifications.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

3. Highlight Your Technical Skills and Experience

Emphasize your knowledge of boiler systems, welding techniques, and fabrication methods.

- Quantify your experience and accomplishments, using specific examples.

- Provide evidence of your certifications and training.

4. Demonstrate Your Problem-Solving Abilities

Share examples of how you’ve successfully identified and resolved problems related to boilers.

- Explain your analytical thought process and technical expertise.

- Highlight your ability to work under pressure and meet deadlines.

5. Convey Your Passion for the Industry

Express your enthusiasm for working with boilers and your commitment to delivering high-quality results.

- Explain why you’re drawn to the field and how your skills and experience make you a suitable candidate.

- Share your contributions to the industry, such as involvement in professional organizations or technical forums.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Boiler Erector interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!