Are you gearing up for a career in Locomotive Boilermaker? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Locomotive Boilermaker and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

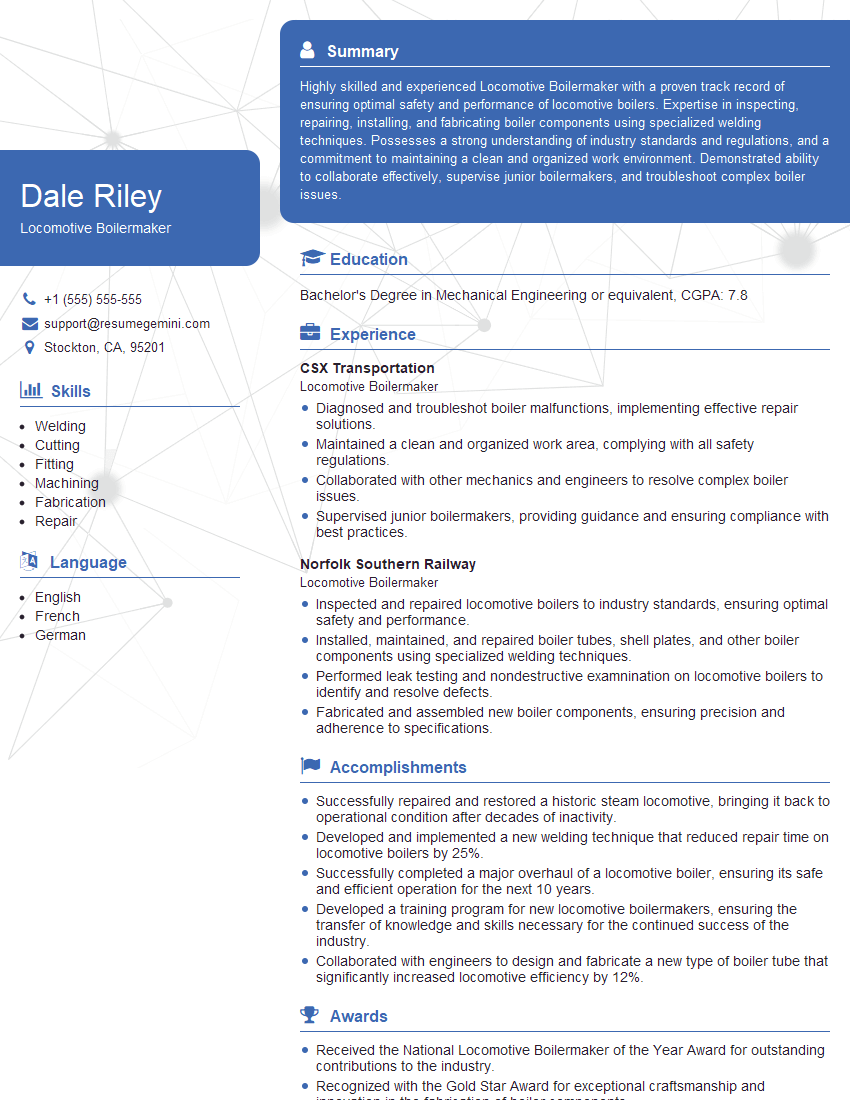

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Locomotive Boilermaker

1. Can you describe the process of inspecting locomotive boilers for defects and maintenance issues?

– Conduct visual inspections to identify potential issues such as cracks, corrosion, wear, and leaks. – Use non-destructive testing methods such as ultrasonic, eddy current, and magnetic particle testing. – Refer to inspection plans and manuals to determine the scope and frequency of scheduled inspections. – Document and report findings, recommending repairs or replacements as necessary.

2. How do you approach the repair and maintenance of boiler tubes, including tube replacement and tube rolling?

Tube Replacement

- Identify the damaged tube and cut it out.

- Clean the tube ends and inspect the surrounding area.

- Install a new tube and expand it into place.

- Hydraulically test to ensure proper fit.

Tube Rolling

- Expand the tube ends using a tube roller.

- Inspect the expanded tube ends and ensure proper contact with the tube sheet.

- Hydraulically test to verify the seal.

3. Can you explain the boiler’s water treatment system, including the purpose of chemical additives and the monitoring of water quality?

– Describe the chemical additives used to prevent corrosion, scale formation, and foaming. – Explain the role of monitoring water quality parameters such as pH, conductivity, and dissolved solids. – Discuss the importance of regular water testing and treatment to ensure boiler efficiency and safety.

4. How do you ensure compliance with industry standards and regulations related to locomotive boiler maintenance?

– Refer to relevant codes and standards, such as ASME Boiler and Pressure Vessel Code. – Stay updated on industry best practices and advancements. – Participate in training and certification programs. – Collaborate with regulatory bodies and inspectors to ensure compliance and obtain necessary approvals.

5. Can you describe the safety precautions and protocols you follow when working with high-pressure boilers?

- Wear appropriate personal protective equipment (PPE) such as flame-resistant clothing, eye protection, and gloves.

- Lock out and tag out boiler systems before performing maintenance.

- Follow proper depressurization and cool-down procedures.

- Inspect safety valves and pressure gauges regularly.

- Be aware of potential hazards such as steam leaks, electrical hazards, and restricted access.

6. How do you troubleshoot locomotive boiler problems, and can you give an example of a troubleshooting scenario?

– Explain the systematic approach to troubleshooting, including gathering data, analyzing symptoms, and identifying potential causes. – Discuss the use of diagnostic tools and equipment. – Provide an example of a troubleshooting scenario, such as addressing a drop in boiler pressure or a steam leak.

7. What techniques do you use to monitor boiler performance and ensure efficient operation?

- Monitor steam pressure, temperature, and flow.

- Conduct regular efficiency tests to evaluate fuel consumption and heat transfer rates.

- Inspect and clean boiler components to maintain proper heat transfer surfaces.

- Adjust burner settings and controls to optimize combustion efficiency.

8. How do you work with other team members and stakeholders, including mechanics, engineers, and supervisors?

- Collaborate with mechanics to perform repairs and maintenance tasks.

- Communicate with engineers to discuss technical issues and plan boiler modifications.

- Follow supervisors’ instructions and coordinate with other team members to ensure efficient workflow.

- Contribute to team discussions and share knowledge and expertise.

9. Can you describe your experience with welding and fabrication techniques used in locomotive boiler maintenance?

- Arc welding processes such as shielded metal arc welding (SMAW) and gas metal arc welding (GMAW).

- Oxy-fuel cutting and brazing techniques.

- Fabricating and installing replacement boiler components, such as tubes, headers, and stays.

- Following welding procedures and quality control standards.

10. How do you stay updated on the latest developments and technologies in locomotive boiler inspection, repair, and maintenance?

- Attend industry conferences and workshops.

- Read technical journals and articles.

- Participate in online forums and discussions.

- Collaborate with manufacturers and suppliers to learn about new products and technologies.

- Pursue additional training and certifications.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Locomotive Boilermaker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Locomotive Boilermaker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Locomotive Boilermakers are responsible for the fabrication, assembly, and repair of locomotive boilers and other pressure vessels. They work with a variety of materials, including steel, aluminum, and composite materials, and use a variety of tools and equipment, including welding machines, cutting torches, and hydraulic presses.

1. Fabrication and Assembly

Locomotive Boilermakers fabricate and assemble new boilers and other pressure vessels according to blueprints and specifications. They cut, shape, and weld metal plates and other components to create the desired shape and size. They also assemble and install various components, such as tubes, headers, and fittings.

- Cut, shape, and weld metal plates and other components to create the desired shape and size.

- Assemble and install various components, such as tubes, headers, and fittings.

2. Repair and Maintenance

Locomotive Boilermakers repair and maintain existing boilers and other pressure vessels. They inspect boilers for damage and wear, and make repairs as needed. They also perform routine maintenance tasks, such as cleaning and lubricating boilers.

- Inspect boilers for damage and wear, and make repairs as needed.

- Perform routine maintenance tasks, such as cleaning and lubricating boilers.

3. Quality Control

Locomotive Boilermakers are responsible for ensuring that boilers and other pressure vessels meet all applicable safety standards. They perform quality control inspections to ensure that all welds and other components are properly made and that the boiler is operating safely.

- Perform quality control inspections to ensure that all welds and other components are properly made and that the boiler is operating safely.

4. Safety

Locomotive Boilermakers must be aware of all safety hazards associated with their work, and they must take appropriate precautions to protect themselves and others. They must also follow all safety regulations and procedures.

- Be aware of all safety hazards associated with their work, and they must take appropriate precautions to protect themselves and others.

- Follow all safety regulations and procedures.

Interview Tips

In order to ace an interview for a Locomotive Boilermaker position, there are several key tips to keep in mind:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific position you are applying for. This will help you better understand the company’s culture, goals, and expectations for the role. It will also allow you to tailor your answers to the interviewer’s questions and demonstrate your interest in the position.

- Visit the company website to learn about their history, mission, and values.

- Read industry news and articles to stay up-to-date on the latest trends and developments.

- Network with people who work in the industry to get insights into the company and the position.

2. Highlight Your Skills and Experience

During the interview, be sure to highlight your skills and experience that are relevant to the position. Be sure to provide specific examples of your work experience and how it has prepared you for the role. You should also be prepared to discuss your technical skills and knowledge, as well as your safety experience.

- Prepare a portfolio of your work to showcase your skills and experience.

- Practice answering common interview questions related to your skills and experience.

- Be prepared to discuss your safety experience and knowledge.

3. Be Prepared to Answer Behavioral Questions

In addition to questions about your skills and experience, the interviewer may also ask you behavioral questions. These questions are designed to assess your personality and work style. Common behavioral questions include “Tell me about a time when you had to overcome a challenge” or “Describe a time when you worked effectively in a team.” When answering behavioral questions, be sure to use the STAR method (Situation, Task, Action, Result) to provide a clear and concise answer.

- Practice answering behavioral questions using the STAR method.

- Prepare a list of examples of your work experience that you can use to answer behavioral questions.

4. Dress Professionally and Arrive on Time

First impressions matter, so be sure to dress professionally for your interview. You should also arrive on time for your interview. Punctuality shows that you are respectful of the interviewer’s time and that you are serious about the position.

- Choose an outfit that is clean, pressed, and appropriate for a professional setting.

- Arrive at the interview location 10-15 minutes early to allow time for unexpected delays.

5. Be Yourself and Be Enthusiastic

Throughout the interview, be yourself and be enthusiastic about the position. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Be genuine and let your personality shine through. Also, be sure to ask questions about the company and the position. This shows that you are interested in the role and that you are taking the interview seriously.

- Be confident and assertive, but don’t be overbearing or aggressive.

- Maintain eye contact with the interviewer and speak clearly and confidently.

- Ask questions about the company and the position to show your interest and enthusiasm.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Locomotive Boilermaker, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Locomotive Boilermaker positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.