Are you gearing up for a career in Manufacturing Assembler? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Manufacturing Assembler and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

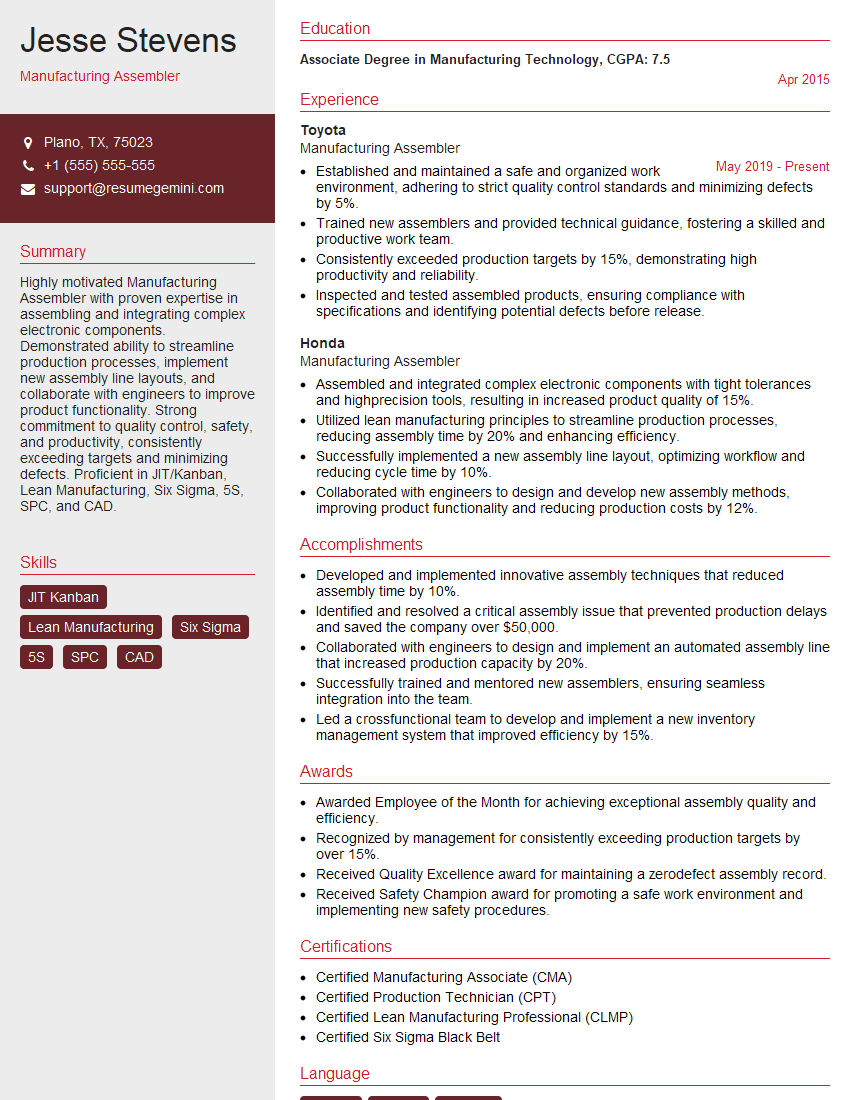

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Manufacturing Assembler

1. Explain the key steps involved in the manufacturing assembly process?

The key steps involved in the manufacturing assembly process include:

- Receiving and inspecting raw materials and components

- Assembling components into subassemblies and final products

- Testing and inspecting assembled products

- Packaging and shipping finished products

2. What are the different types of assembly methods used in manufacturing?

Manual Assembly

- Involves assembling components by hand using tools such as screwdrivers, wrenches, and pliers.

Automated Assembly

- Involves using machines or robots to perform assembly tasks, reducing the need for manual labor.

Hybrid Assembly

- Combines manual and automated assembly methods, with machines performing repetitive tasks while humans handle more complex or delicate operations.

3. What are the key quality control measures implemented in a manufacturing assembly process?

Key quality control measures implemented in a manufacturing assembly process include:

- Visual inspections of components and assemblies

- Dimensional measurements using calipers, micrometers, and other tools

- Functional testing to ensure products meet performance specifications

- Statistical process control (SPC) techniques to monitor and improve processes

4. Describe the importance of safety procedures in a manufacturing assembly environment.

Safety procedures are crucial in a manufacturing assembly environment to:

- Prevent accidents and injuries to employees

- Protect equipment and machinery from damage

- Maintain a safe and healthy work environment

- Comply with regulatory requirements and industry standards

5. How do you handle working in a fast-paced manufacturing assembly environment?

In a fast-paced manufacturing assembly environment, I manage to maintain efficiency and accuracy by:

- Prioritizing tasks and working within set timeframes

- Following established assembly procedures and quality standards

- Communicating effectively with colleagues and supervisors

- Staying focused and avoiding distractions

6. Describe your experience in using assembly tools and equipment.

Throughout my experience, I have worked with a variety of assembly tools and equipment, including:

- Hand tools (e.g., screwdrivers, wrenches, pliers)

- Power tools (e.g., drills, grinders, sanders)

- Measuring and inspection equipment (e.g., calipers, micrometers)

- Automated assembly machines (e.g., robots, conveyors)

7. How do you ensure accuracy and precision in your assembly work?

To ensure accuracy and precision in my assembly work, I adhere to the following practices:

- Thoroughly reviewing assembly instructions and specifications

- Using appropriate tools and equipment calibrated to industry standards

- Implementing quality control measures (e.g., visual inspections, dimensional measurements)

- Seeking clarification from supervisors or colleagues when needed

8. Give an example of a time when you had to troubleshoot a problem in an assembly process.

During a recent assembly project, I encountered an issue where a subassembly was not fitting properly into the main assembly. Through troubleshooting, I identified that a component was slightly misaligned. I adjusted the component and successfully assembled the subassembly without compromising quality.

9. How do you stay up-to-date with the latest assembly techniques and technologies?

To stay up-to-date with the latest assembly techniques and technologies, I regularly:

- Attend industry conferences and workshops

- Read technical publications and articles

- Engage in online forums and social media groups related to manufacturing assembly

- Explore new technologies through research and discussions with colleagues

10. What are your strengths and weaknesses as a Manufacturing Assembler?

Strengths:

- Strong attention to detail and accuracy

- Proficient in manual and automated assembly techniques

- Ability to work efficiently in a fast-paced environment

- Excellent communication and teamwork skills

Weaknesses:

- Limited experience with complex electrical assembly

- Working extended hours may be challenging at times

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Manufacturing Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Manufacturing Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Manufacturing Assemblers play a crucial role in the production of numerous products, from electronics and automobiles to medical devices and aerospace components. Their primary responsibilities encompass the following:

1. Assembly and Installation

Assemblers meticulously assemble various components, parts, and subassemblies according to precise instructions and specifications.

- Follow detailed assembly procedures and blueprints

- Utilize a range of tools and equipment to connect and fasten components

- Calibrate and adjust assembled units to meet performance standards

2. Quality Control

Assemblers conduct rigorous quality checks throughout the assembly process to ensure products meet established standards.

- Inspect incoming materials and components for defects

- Monitor assembly processes and identify potential issues

- Conduct final inspections to verify product quality and functionality

3. Production Support

Assemblers contribute to the smooth operation of production lines by supporting various tasks.

- Maintain a clean and organized work area

- Assist in troubleshooting and resolving production issues

- Participate in continuous improvement initiatives

4. Safety and Compliance

Adhering to safety regulations and maintaining a safe work environment is paramount for assemblers.

- Follow established safety protocols and wear appropriate protective gear

- Handle hazardous materials with care and in accordance with regulations

- Maintain a clean and clutter-free work area to prevent accidents

Interview Tips

To ace your interview for a Manufacturing Assembler position, consider the following tips:

1. Research the Company and Industry

Demonstrate your interest and enthusiasm by researching the company’s products, services, and industry trends.

- Visit the company’s website to gather information about their mission, values, and recent developments

- Explore industry publications and news articles to stay informed about the latest advancements and challenges

2. Highlight Your Skills and Experience

Tailor your resume and interview responses to showcase your relevant skills and experience.

- Emphasize your proficiency in assembly techniques, quality control methods, and production support tasks

- Quantify your accomplishments and provide specific examples of how you have contributed to the success of previous projects

3. Demonstrate Your Attention to Detail

Manufacturing Assemblers must possess a keen eye for detail and accuracy.

- Describe your systematic approach to assembly processes, ensuring precision and adherence to specifications

- Share examples of how you have identified and resolved assembly issues or quality defects

4. Emphasize Your Safety Consciousness

Safety is paramount in manufacturing environments.

- Highlight your commitment to following established safety protocols and wearing appropriate protective gear

- Discuss your understanding of hazardous materials handling and waste disposal procedures

5. Showcase Your Teamwork and Communication Skills

Manufacturing Assemblers often work in teams and communicate with various stakeholders.

- Describe your experience collaborating with colleagues, supervisors, and customers

- Emphasize your ability to communicate effectively, both verbally and in writing

6. Prepare Relevant Questions

Asking well-informed questions at the end of the interview demonstrates your interest and engagement.

- Inquire about the company’s plans for future growth or new product development

- Ask about opportunities for professional development and training within the organization

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Manufacturing Assembler interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.