Feeling lost in a sea of interview questions? Landed that dream interview for Epoxy Specialist but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Epoxy Specialist interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

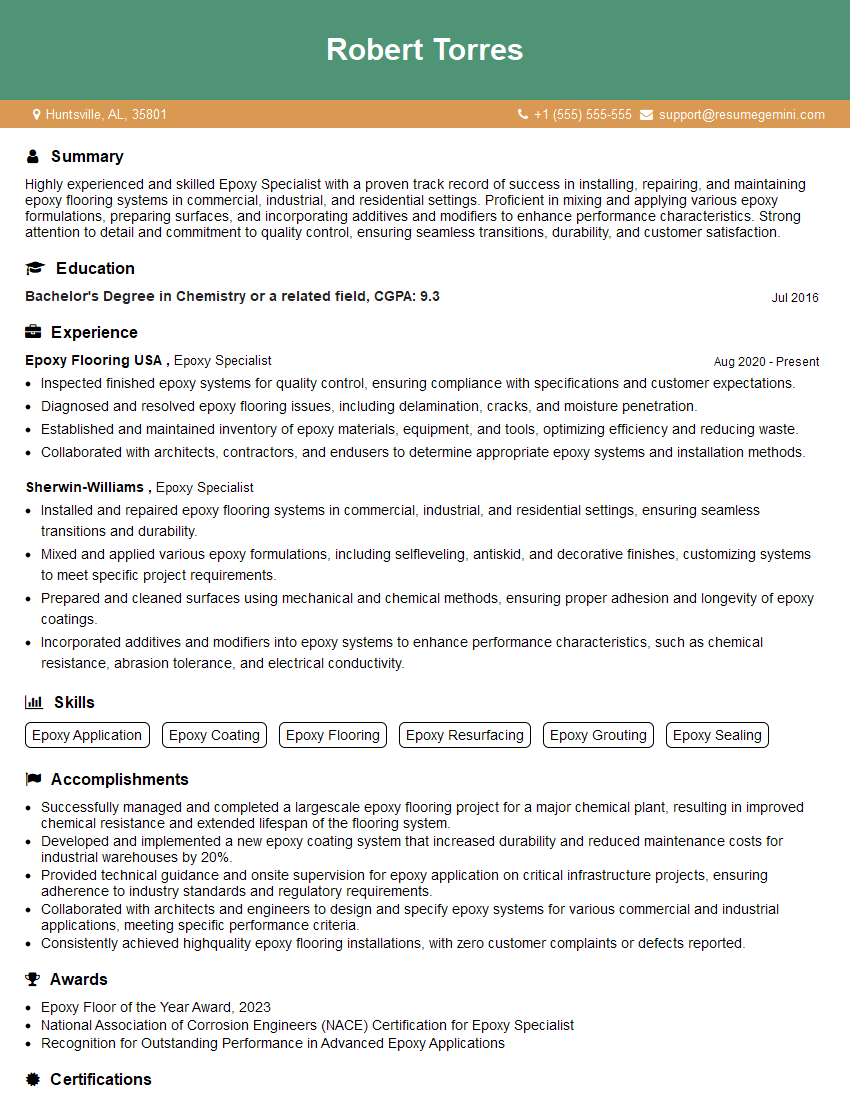

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Epoxy Specialist

1. Tell me about your experience with epoxy flooring installation?

In my previous role as an Epoxy Specialist, I was responsible for the installation of epoxy flooring in various commercial and industrial settings. I have extensive experience in preparing surfaces, mixing and applying epoxy coatings, and ensuring proper curing and finishing. I am proficient in using different types of epoxy systems, including self-leveling, trowelable, and flake-filled epoxies.

2. What are the key factors to consider when preparing a surface for epoxy flooring installation?

Surface condition:

- The surface should be clean, dry, and free of any contaminants, such as grease, oil, or dust.

- Any cracks or imperfections should be repaired before applying the epoxy coating.

Moisture content:

- The surface should have a moisture content below 4% to ensure proper adhesion of the epoxy coating.

- Moisture testing may be necessary to determine the moisture level of the surface.

Temperature:

- The surface and surrounding environment should be at the appropriate temperature range for the specific epoxy system being used.

- Typically, epoxy coatings are applied at temperatures between 50°F and 75°F.

3. How do you calculate the amount of epoxy needed for a given project?

- Calculate the total square footage of the area to be coated.

- Determine the recommended coverage rate of the epoxy system being used (usually specified by the manufacturer).

- Multiply the square footage by the coverage rate to determine the total amount of epoxy needed.

- Add an additional 10-15% for material loss and application variances.

4. What are the different types of epoxy flooring systems available?

- Self-leveling epoxy: Creates a smooth, seamless finish, ideal for areas requiring a high-gloss appearance.

- Trowelable epoxy: Applied with a trowel, providing a thicker, textured finish, suitable for areas with heavy traffic.

- Flake-filled epoxy: Contains decorative flakes that are broadcast into the wet epoxy, creating a unique and aesthetically pleasing look.

- Metallic epoxy: Infused with metallic pigments, producing a shimmering, three-dimensional effect.

5. How do you ensure proper curing of epoxy flooring?

- Maintain the appropriate temperature and humidity levels during the curing process.

- Avoid foot traffic or heavy loads on the newly installed epoxy until it has fully cured.

- Use fans or ventilation to promote air circulation and remove any fumes.

- Follow the manufacturer’s recommended curing time, which can vary depending on the epoxy system and environmental conditions.

6. What are some common problems that can occur during epoxy flooring installation and how do you troubleshoot them?

- Bubbles: Can be caused by trapped air or moisture. Use a roller or brush to release the bubbles.

- Orange peel: An uneven surface texture. Adjust the application technique or use a different epoxy system.

- Discoloration: Can be caused by exposure to UV light or chemicals. Apply a protective topcoat or use a UV-resistant epoxy system.

- Delamination: Separation of the epoxy from the substrate. Ensure proper surface preparation and adhesion.

7. How do you maintain epoxy flooring to ensure its longevity?

- Regular cleaning with a pH-neutral cleaner.

- Avoid using abrasive cleaners or harsh chemicals.

- Protect the flooring from heavy loads and impact.

- Reapply a protective topcoat as needed to maintain the glossy finish and protect against wear and tear.

8. What safety precautions should be taken when working with epoxy?

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a respirator.

- Ensure proper ventilation to avoid inhalation of fumes.

- Handle epoxy in a well-ventilated area.

- Dispose of epoxy and related materials according to local regulations.

9. How do you stay up-to-date with the latest advancements in epoxy flooring technology?

- Attend industry conferences and workshops.

- Read trade publications and online resources.

- Consult with manufacturers and suppliers for product updates and technical information.

- Participate in online forums and discussion groups dedicated to epoxy flooring.

10. Describe a challenging epoxy flooring project you have worked on and how you overcame the challenges.

In a recent project, we encountered a large industrial warehouse with an uneven and heavily damaged concrete floor. To address these challenges, we used a combination of grinding, patching, and leveling compounds to create a smooth and stable surface. We then installed a self-leveling epoxy coating that provided excellent leveling and a high-gloss finish, despite the floor’s imperfections. The end result was a durable and aesthetically pleasing epoxy floor that met the client’s specifications.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Epoxy Specialist.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Epoxy Specialist‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Epoxy Specialist is responsible for various aspects of epoxy flooring installation and maintenance. Key job responsibilities include:1. Surface Preparation

Prepare surfaces for epoxy application by cleaning, grinding, and repairing cracks or imperfections.

2. Epoxy Application

Mix, apply, and spread epoxy resins, ensuring proper thickness and leveling.

3. Finish and Inspection

Apply protective coatings or non-slip finishes, inspect completed flooring for quality, and ensure adherence to specifications.

4. Equipment Maintenance

Maintain equipment used in epoxy application, including mixers, grinders, and safety gear.

5. Safety and Compliance

Follow safety protocols, handle hazardous materials responsibly, and comply with environmental regulations.

Interview Tips

To ace an Epoxy Specialist interview, consider the following tips:1. Research the Company and Role

Gather information about the company’s culture, values, and specific project requirements.

Review the job description thoroughly to understand the responsibilities and expectations.

2. Highlight Experience and Skills

Emphasize your experience and skills in epoxy flooring installation, surface preparation, and equipment handling.

Present examples that demonstrate your ability to achieve high-quality results and meet project deadlines.

3. Prepare for Technical Questions

Expect questions about epoxy chemistry, application techniques, and troubleshooting common issues.

Prepare answers that showcase your knowledge and problem-solving abilities.

4. Demonstrate Safety Awareness

Highlight your understanding of safety protocols and best practices in handling epoxy materials.

Explain how you ensure the safety of yourself and others during epoxy application.

5. Ask Informed Questions

At the end of the interview, ask thoughtful questions about the company’s projects, team dynamics, and opportunities for growth.

This shows your engagement and interest in the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Epoxy Specialist interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.