Are you gearing up for an interview for a Kiln Door Builder position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Kiln Door Builder and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

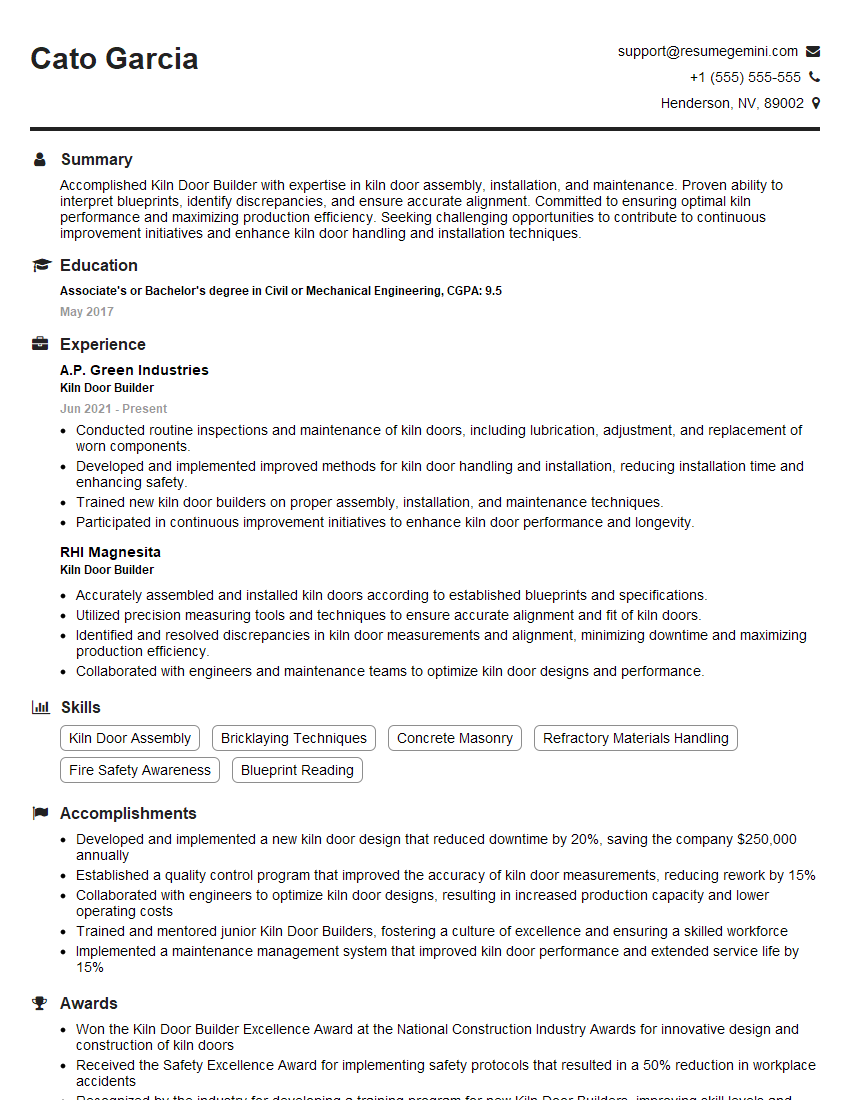

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Kiln Door Builder

1. Describe the key steps involved in designing a custom kiln door?

The key steps involved in designing a custom kiln door are as follows:

- Consultation: Meeting with the customer to discuss their specific requirements and project specifications.

- Site survey: Visiting the project site to assess the existing kiln and door opening, as well as any potential constraints.

- Design: Creating detailed drawings and specifications for the custom door, ensuring it meets the customer’s requirements and industry standards.

- Engineering: Performing structural calculations and analysis to determine the door’s load-bearing capacity and durability.

- Material selection: Choosing the appropriate materials based on factors such as temperature resistance, corrosion resistance, and structural strength.

- Fabrication: Cutting, welding, and assembling the door components according to the design specifications.

- Quality control: Inspecting the finished door to ensure it meets the required standards and specifications.

- Installation: Installing the custom door into the kiln, ensuring a secure and proper fit.

2. Explain the different types of kiln doors and their applications.

There are various types of kiln doors, each with its own specific applications:

- Swing doors: Hinged at one side, these doors are commonly used for smaller kilns and provide easy access.

- Sliding doors: Horizontally or vertically sliding, these doors are suitable for larger kilns where space is a constraint.

- Roll-up doors: Consisting of interlocking slats that roll up into a drum, these doors are commonly used for high-temperature kilns.

- Lift-away doors: Easily removed and re-installed, these doors are ideal for kilns requiring frequent access or maintenance.

- Pneumatic doors: Operated by air pressure, these doors provide automated operation and can be integrated with safety systems.

3. How do you determine the appropriate materials for a kiln door based on temperature and atmosphere conditions?

The selection of materials for a kiln door is crucial and depends on the specific temperature and atmosphere conditions within the kiln:

- Temperature resistance: Materials such as stainless steel, high-temperature alloys, and ceramics are used for doors exposed to extreme temperatures.

- Corrosion resistance: Acid-resistant materials like stainless steel and alloys are preferred for kilns with acidic atmospheres.

- Thermal expansion: Materials with low thermal expansion, such as refractory bricks and ceramics, are chosen to minimize door deformation.

- Structural strength: The door’s load-bearing capacity is determined by the materials used, their thickness, and design.

4. Explain the principles of heat transfer and how they apply to kiln door design.

Heat transfer principles are essential for designing efficient kiln doors:

- Conduction: Heat transfer through direct contact between the door and the kiln atmosphere.

- Convection: Heat transfer through the movement of hot air or gases around the door.

- Radiation: Heat transfer through electromagnetic waves emitted by the kiln.

- Insulation: Utilizing materials with low thermal conductivity to reduce heat loss through the door.

- Gaskets and seals: Ensuring a tight seal around the door’s perimeter to prevent air leakage and heat loss.

5. Describe the safety considerations that must be taken into account when designing and installing a kiln door.

Safety is paramount in kiln door design and installation:

- Thermal protection: Providing insulation and shielding to prevent operators from exposure to extreme temperatures.

- Fire safety: Using fire-resistant materials and incorporating safety features like automatic shut-offs and interlocks.

- Pinch points: Avoiding sharp edges or moving parts in close proximity to operators.

- Electrical safety: Ensuring proper grounding and adherence to electrical codes.

- Emergency access: Providing a means of escape or quick access in case of emergencies.

- Compliance: Adhering to applicable safety standards and regulations.

6. Explain the use of refractory materials in kiln door construction.

Refractory materials play a critical role in kiln door construction:

- High-temperature resistance: Withstanding extreme temperatures without melting or degrading.

- Low thermal conductivity: Minimizing heat loss and improving energy efficiency.

- Chemical stability: Resisting reactions with acidic or corrosive atmospheres within the kiln.

- Insulation: Forming a protective barrier to prevent heat transfer through the door.

- Structural strength: Providing support and stability to the door structure.

7. Describe the maintenance requirements for kiln doors and how to ensure their long-term performance.

Regular maintenance is essential to maintain the performance of kiln doors:

- Regular inspections: Checking for any damage, wear, or corrosion.

- Cleaning and lubrication: Removing debris and applying lubricants to moving parts.

- Gasket replacement: Replacing worn or damaged gaskets to maintain proper sealing.

- Electrical component maintenance: Ensuring proper operation of sensors, actuators, and other electrical components.

- Refractory repairs: Repairing or replacing any damaged refractory lining.

8. Explain the different types of actuators used in automated kiln doors and their advantages and disadvantages.

Automated kiln doors utilize various types of actuators:

- Pneumatic actuators: Using compressed air to provide force and motion, they are fast-acting but require an air supply.

- Electric actuators: Using electric motors to generate force, they are precise and energy-efficient but can be slower than pneumatic actuators.

- Hydraulic actuators: Using hydraulic fluid to transmit force, they offer high power and precision but require a hydraulic system.

- Electro-mechanical actuators: Combining electric motors and mechanical linkages, they provide a balance of speed, power, and efficiency.

9. Describe the role of sensors in kiln door operation and how they contribute to safety and efficiency.

Sensors play a crucial role in kiln door operation:

- Temperature sensors: Monitoring the temperature around the door to prevent overheating and damage.

- Position sensors: Detecting the door’s position to ensure proper opening and closing.

- Safety sensors: Triggering alarms or emergency shutdowns in case of unsafe conditions like over-temperature or obstruction.

- Interlocks: Preventing the door from opening under unsafe conditions, such as when the kiln is in operation.

- Diagnostic sensors: Monitoring the performance of the door and its components to facilitate predictive maintenance.

10. Explain your experience in using design software for kiln door development.

I have extensive experience in using design software for kiln door development, including:

- CAD software (Computer-Aided Design): Creating detailed drawings and models of kiln doors.

- FEA software (Finite Element Analysis): Performing structural analysis and simulations to optimize door design.

- CFD software (Computational Fluid Dynamics): Analyzing heat transfer and airflow patterns around the door to improve efficiency.

- CAM software (Computer-Aided Manufacturing): Generating CNC (Computer Numerical Control) code for automated fabrication of kiln doors.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Kiln Door Builder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Kiln Door Builder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Kiln Door Builders are responsible for fabricating, installing, and maintaining kiln doors and related equipment used in the production of cement, lime, and other materials. They work independently and as part of a team to ensure that the kilns operate efficiently and safely.

1. Fabricate and Install Kiln Doors

Kiln Door Builders use a variety of materials and techniques to fabricate and install kiln doors. They must have a strong understanding of the properties of different materials and how they will perform under the extreme conditions inside a kiln.

- Select and prepare materials, such as steel, refractory brick, and insulation.

- Cut, shape, and weld steel components using a variety of tools and equipment.

- Assemble and install kiln doors according to specifications.

- Ensure that kiln doors meet all safety and quality standards.

2. Maintain Kiln Doors and Related Equipment

Kiln Door Builders are also responsible for maintaining kiln doors and related equipment. They must be able to identify and repair problems quickly and efficiently to minimize downtime.

- Inspect kiln doors and related equipment regularly for signs of wear and tear.

- Repair or replace damaged components as needed.

- Lubricate and adjust moving parts.

- Keep work area clean and organized.

3. Work Safely

Working around kilns can be dangerous, so Kiln Door Builders must be aware of the potential hazards and take precautions to protect themselves and others. They must wear appropriate personal protective equipment (PPE) and follow all safety procedures.

- Identify and assess potential hazards.

- Follow all safety procedures.

- Wear appropriate PPE.

- Use tools and equipment properly.

4. Work Independently and as Part of a Team

Kiln Door Builders often work independently, but they also must be able to work as part of a team. They must be able to communicate effectively with other workers and supervisors.

- Work independently and as part of a team.

- Communicate effectively with others.

- Follow instructions and directions.

- Meet deadlines and commitments.

Interview Tips

Preparing for a Kiln Door Builder interview can be daunting, but with the right preparation, you can increase your chances of success. Here are a few tips to help you ace your interview:

1. Research the Company and the Position

Before your interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and goals. It will also help you tailor your answers to the specific requirements of the position.

- Visit the company’s website.

- Read industry news and articles.

- Talk to people who work for the company.

2. Practice Answering Common Interview Questions

There are a few common interview questions that you are likely to be asked, regardless of the position you are applying for. It is important to practice answering these questions so that you can do so confidently and concisely.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What are your salary expectations?

3. Be Prepared to Talk About Your Experience

The interviewer will want to know about your experience and how it relates to the position you are applying for. Be prepared to talk about your skills, accomplishments, and any relevant experience you have.

- Highlight your skills and accomplishments.

- Use specific examples to illustrate your experience.

- Quantify your results whenever possible.

4. Ask Questions

At the end of the interview, the interviewer will likely ask if you have any questions. This is your opportunity to ask about the company, the position, and the next steps in the hiring process. Asking thoughtful questions shows that you are interested in the position and that you are taking the interview seriously.

- Ask about the company’s culture.

- Ask about the position’s responsibilities.

- Ask about the next steps in the hiring process.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Kiln Door Builder, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Kiln Door Builder positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.