Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Ladle Patcher interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Ladle Patcher so you can tailor your answers to impress potential employers.

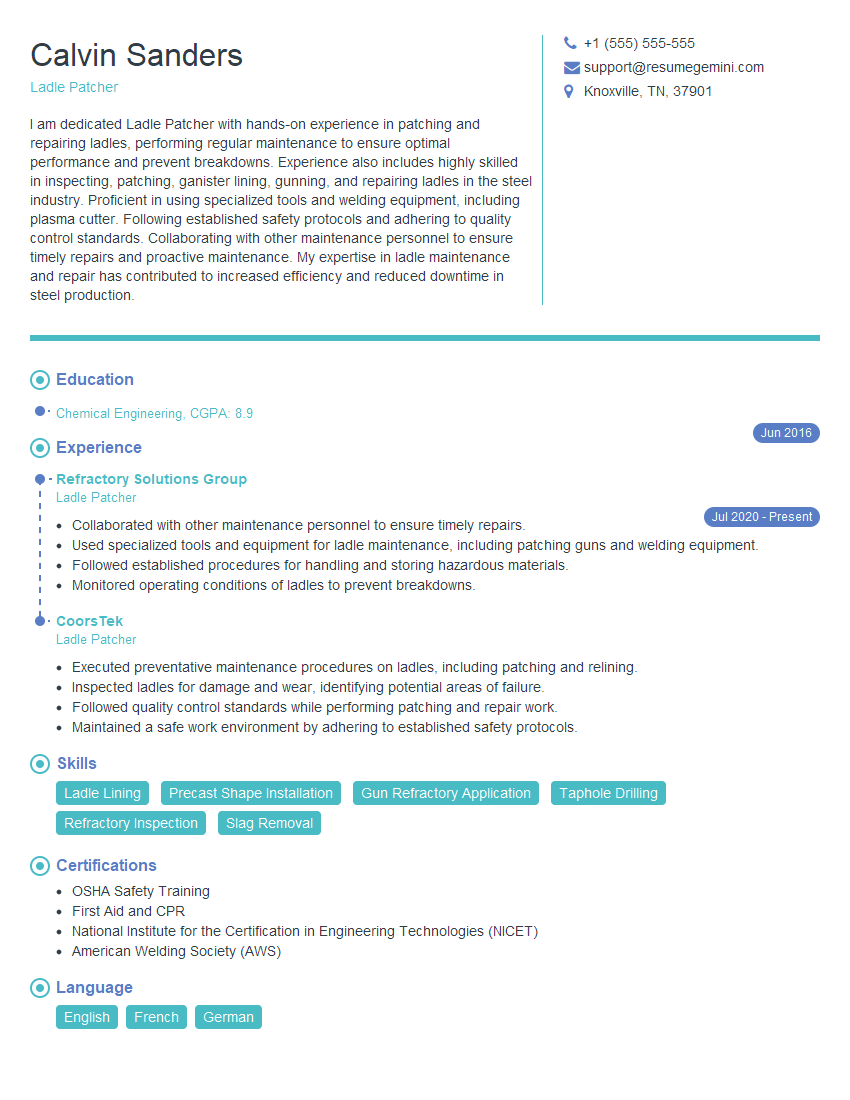

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ladle Patcher

1. What are the key responsibilities of a Ladle Patcher?

The key responsibilities of a Ladle Patcher include:

- Inspecting ladles for damage and wear

- Preparing and repairing ladles using refractory materials

- Operating and maintaining patching equipment

- Ensuring that ladles meet safety and quality standards

- Working with other members of the production team to maintain a safe and efficient work environment

2. What types of refractory materials are used to repair ladles?

The types of refractory materials used to repair ladles include:

- Fireclay

- High-alumina

- Magnesia

- Zirconia

- Carbon

The specific type of refractory material used will depend on the ladle’s operating conditions and the type of damage.

3. What are the steps involved in preparing a ladle for patching?

The steps involved in preparing a ladle for patching include:

- Inspecting the ladle for damage

- Cleaning the ladle

- Preheating the ladle

- Applying a release agent

- Installing a mold or form

4. What are the different methods of repairing ladles?

The different methods of repairing ladles include:

- Gunning

- Casting

- Hand patching

- Welding

The specific method used will depend on the type of damage and the operating conditions of the ladle.

5. What are the safety precautions that must be taken when patching ladles?

The safety precautions that must be taken when patching ladles include:

- Wearing appropriate protective clothing and equipment

- Working in a well-ventilated area

- Using caution when handling hot materials

- Being aware of the potential hazards of the materials being used

- Following all safety procedures and guidelines

6. What are the quality control procedures that are used to ensure that ladles are properly repaired?

The quality control procedures that are used to ensure that ladles are properly repaired include:

- Inspecting the repaired ladle for defects

- Testing the repaired ladle to ensure that it meets the required specifications

- Documenting the repair work

7. What is the importance of maintaining ladles in good condition?

Maintaining ladles in good condition is important for the following reasons:

- To prevent accidents

- To improve productivity

- To reduce costs

- To maintain the quality of the products being produced

8. What are the challenges of working as a Ladle Patcher?

The challenges of working as a Ladle Patcher include:

- Working in a hot and hazardous environment

- Working with heavy and dangerous materials

- Working under tight deadlines

- Working in a team environment

9. What are the rewards of working as a Ladle Patcher?

The rewards of working as a Ladle Patcher include:

- Job satisfaction

- Competitive salary

- Opportunities for advancement

- A sense of accomplishment

10. Why are you interested in working as a Ladle Patcher?

I am interested in working as a Ladle Patcher because I have a strong interest in the steel industry and I am looking for a challenging and rewarding career. I am confident that my skills and experience would make me a valuable asset to your team.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ladle Patcher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ladle Patcher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Ladle Patcher, you will play a vital role in maintaining and repairing ladles, critical equipment in metal manufacturing facilities. Your duties will encompass:

1. Ladle Maintenance and Repair:

Inspecting ladles for cracks, damage, and wear

- Removing and replacing worn or damaged components

- Patching and repairing cracks and holes using refractory materials

- Relining ladles with new refractory bricks

2. Refractory Material Handling:

Preparing refractory materials for application

- Mixing and installing refractory materials according to specifications

- Ensuring proper drying and curing of refractory materials

3. Equipment Operation:

Operating equipment such as jackhammers, cutting torches, and grinders

- Using specialized tools and techniques to repair ladles

4. Safety and Compliance:

Adhering to safety regulations and following established procedures

- Maintaining a clean and organized work area

- Wearing appropriate personal protective equipment (PPE)

Interview Tips

To ace the interview for a Ladle Patcher position, consider the following tips:

1. Research the Company and Industry:

Familiarize yourself with the company, its products or services, and the metal manufacturing industry.

- Visit the company’s website and social media pages.

- Read industry publications and news articles.

2. Highlight Relevant Experience:

Emphasize your previous experience in ladle maintenance or related fields.

- Quantify your accomplishments using specific metrics, such as the number of ladles repaired or the time saved.

- Be prepared to discuss your knowledge of refractory materials and repair techniques.

3. Demonstrate Safety Consciousness:

Stress your commitment to safety and compliance.

- Provide examples of how you have ensured safety in previous roles.

- Discuss your understanding of the importance of PPE and proper work procedures.

4. Show Enthusiasm for Continuous Learning:

Express your eagerness to learn and stay updated with industry developments.

- Mention any training or certifications you have obtained.

- Ask questions about the company’s training and development opportunities.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Ladle Patcher interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!