Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Ladle Builder interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Ladle Builder so you can tailor your answers to impress potential employers.

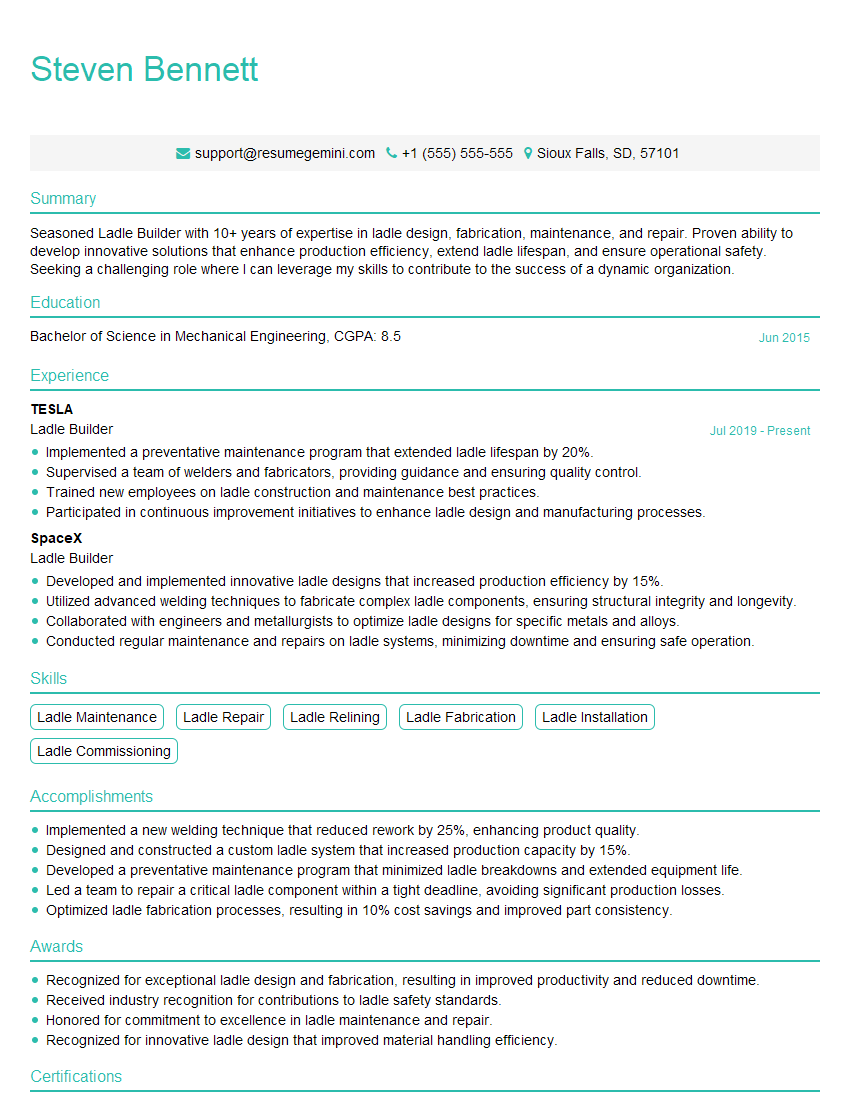

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ladle Builder

1. Describe the process of designing a ladle for a steelmaking facility, including the factors that need to be considered?

- Determine the capacity and shape of the ladle based on the production requirements.

- Select materials that can withstand the high temperatures and corrosive nature of molten steel.

- Design the ladle’s refractory lining to protect the shell from heat and erosion.

- Incorporate features such as pouring spouts, slag dams, and trunnions for handling and pouring.

- Ensure compliance with industry standards and safety regulations.

2. Explain the different types of refractories used in ladle construction and their properties?

Acidic Refractories

- Made from silica or fireclay

- Suitable for acidic slags and molten steel with low basicity

- High thermal conductivity

Basic Refractories

- Made from magnesia, dolomite, or lime

- Suitable for basic slags and molten steel with high basicity

- Lower thermal conductivity than acidic refractories

3. How do you ensure the quality and reliability of ladle refractory linings?

- Use high-quality refractory materials and bonding agents.

- Follow proper installation techniques and curing procedures.

- Conduct regular inspections and maintenance to monitor the condition of the lining.

- Utilize predictive modeling and data analysis to identify potential problems.

- Collaborate with refractory suppliers to optimize lining performance.

4. Describe the different methods of preheating ladles and their advantages and disadvantages?

Electric Induction Heating

- Advantages: Uniform heating, precise temperature control

- Disadvantages: High energy consumption, complex equipment

Gas-Fired Heating

- Advantages: Lower cost, simple equipment

- Disadvantages: Less uniform heating, potential for contamination

Radiant Heating

- Advantages: Fast heating, low energy consumption

- Disadvantages: Non-uniform heating, potential for temperature overshoot

5. How do you manage the thermal stresses that occur in ladles during use?

- Use materials with low thermal expansion coefficients.

- Incorporate expansion joints and flexible elements in the ladle design.

- Control the temperature gradient within the ladle during heating and cooling cycles.

- Monitor the ladle’s structural integrity through regular inspections and non-destructive testing.

6. Describe the safety precautions that you take when working with ladles?

- Wear appropriate protective gear (e.g., heat-resistant clothing, gloves, helmet).

- Ensure proper grounding and electrical safety.

- Follow lifting and handling procedures.

- Maintain a safe distance from hot ladles and molten metal.

- Be aware of potential hazards such as spills, explosions, and burns.

7. How do you troubleshoot common problems that arise with ladles?

- Refractory damage: Inspect for cracks, erosion, or contamination.

- Thermal stress: Check for bowing, bulging, or cracking.

- Electrical issues: Test for grounding, insulation, and loose connections.

- Hydraulic problems: Inspect for leaks, pressure issues, or component malfunctions.

- Pouring difficulties: Examine the pouring spout, slag dam, and stopper system.

8. Explain the role of automation and technology in modern ladle design and operation?

- Automated ladle handling systems reduce manual labor and improve safety.

- Sensors and monitoring systems provide real-time data on ladle temperature, refractory condition, and structural integrity.

- Predictive analytics help identify potential problems and optimize maintenance schedules.

- Advanced simulations and modeling tools allow for more precise design and analysis.

9. How do you stay informed about the latest advancements and best practices in ladle building?

- Attend industry conferences and workshops.

- Read technical publications and research papers.

- Collaborate with experts in the field.

- Participate in professional organizations.

- Stay updated on supplier innovations and product developments.

10. What are your career goals and aspirations as a Ladle Builder?

- Advance my knowledge and expertise in ladle design and construction.

- Contribute to the development of innovative and sustainable ladle solutions.

- Assume leadership roles in the industry and mentor future professionals.

- Collaborate with customers and colleagues to optimize ladle performance and safety.

- Stay abreast of emerging technologies and best practices to drive continuous improvement.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ladle Builder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ladle Builder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Ladle Builder is a skilled professional who plays a crucial role in the production of steel and other metals. Their primary responsibility is to construct and maintain ladles, which are essential vessels for transferring molten metal during various stages of metal production. Here are the key job responsibilities of a Ladle Builder:

1. Ladle Construction

Building and assembling new ladles of varying sizes and capacities based on specifications and engineering drawings.

- Fabricating ladle shells, trunnions, and other components using welding, cutting, and forming techniques.

- Installing refractory linings to protect the ladle from extreme temperatures and chemical reactions.

2. Ladle Maintenance and Repair

Performing scheduled inspections and preventative maintenance on existing ladles to ensure their safe and efficient operation.

- Inspecting ladles for wear, damage, and corrosion.

- Repairing or replacing defective components, such as trunnions, bearings, and relining refractories.

3. Quality Control

Ensuring the quality and integrity of ladles throughout the construction and maintenance process.

- Conducting non-destructive testing (NDT) to detect any defects in materials.

- Adhering to established quality control standards and procedures to maintain a high level of workmanship.

4. Safety and Compliance

Understanding and complying with all relevant safety regulations and guidelines.

- Following proper handling and storage procedures for hazardous materials.

- Wearing appropriate personal protective equipment (PPE).

Interview Tips

To ace an interview for a Ladle Builder position, it is essential to demonstrate your technical skills, knowledge of industry standards, and a strong commitment to safety. Here are some interview tips to help you prepare:

1. Research the Company and Position

Before the interview, take the time to thoroughly research the company and the specific Ladle Builder position. This will give you a better understanding of their operations, requirements, and expectations.

- Visit the company website to learn about their products, services, and company culture.

- Review the job description carefully and identify the key skills and responsibilities.

2. Highlight Your Technical Skills

In the interview, emphasize your technical abilities and experience in ladle construction and maintenance. Be prepared to discuss specific techniques and methodologies you have used.

- Describe your proficiency in welding, cutting, and forming techniques.

- Explain your knowledge of refractory lining materials and installation methods.

3. Showcase Your Problem-Solving Abilities

Ladle Builders often encounter unexpected challenges during construction and maintenance. Be prepared to share examples of how you have solved problems and overcome obstacles in your previous roles.

- Discuss a situation where you diagnosed and repaired a ladle issue efficiently.

- Explain how you have implemented innovative solutions to improve ladle performance or safety.

4. Demonstrate Your Safety and Compliance Knowledge

Emphasize your understanding of safety protocols and industry regulations. Explain how you ensure the safe handling and operation of ladles in your workplace.

- Describe your familiarity with relevant safety standards, such as OSHA and ANSI.

- Discuss your experience in conducting safety inspections and adhering to established procedures.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Ladle Builder, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Ladle Builder positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.