Feeling lost in a sea of interview questions? Landed that dream interview for Reliner but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Reliner interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

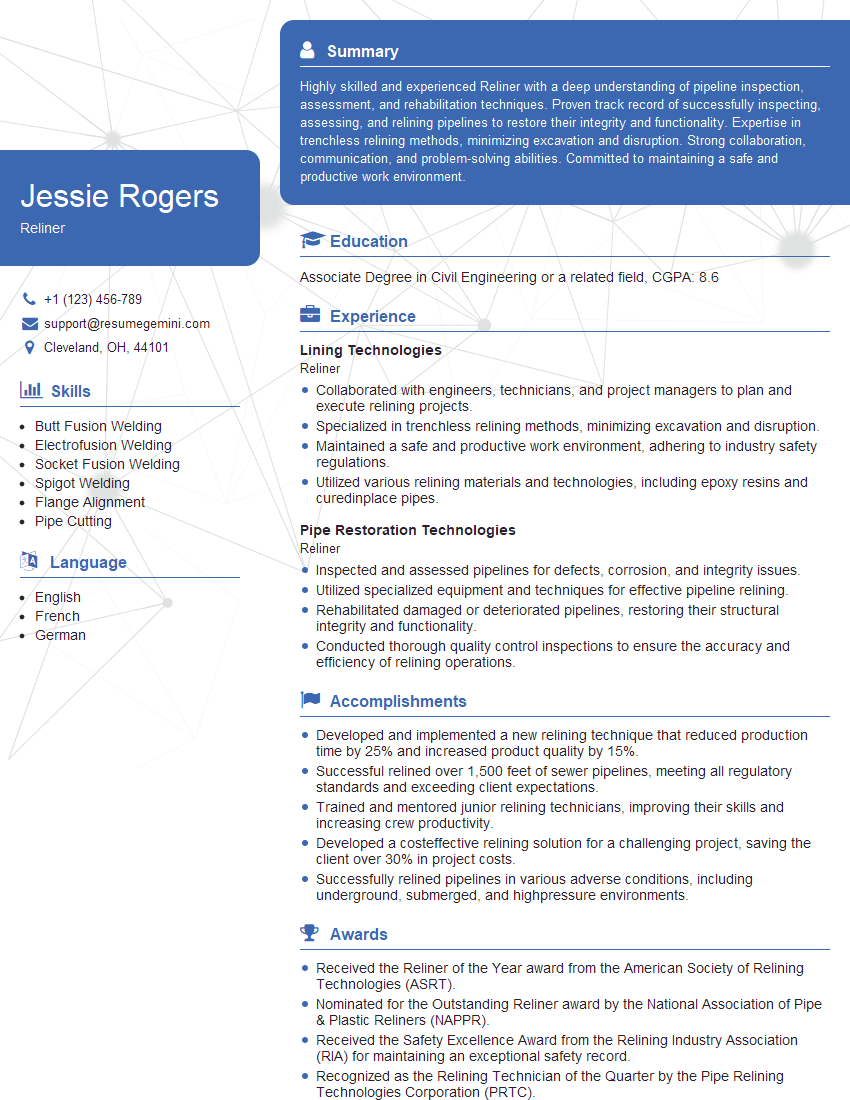

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Reliner

1. What are the different types of relining materials available?

There are several types of relining materials available, including:

- Cured-in-place pipe (CIPP): A flexible liner that is inserted into the existing pipe and then cured, creating a new inner pipe.

- Slip lining: A pipe made of a flexible material, such as polyethylene, that is inserted into the existing pipe and secured.

- Spray lining: A coating that is applied to the interior of the existing pipe, creating a new inner layer.

- Roll-down lining: A lining material that is rolled down the inside of the existing pipe and secured.

2. What are the factors to consider when selecting a relining material?

The following factors should be considered when selecting a relining material:

- The condition of the existing pipe

- The diameter and length of the pipe

- The flow rate and pressure

- The budget

- The availability of skilled labor

3. What are the advantages of relining over traditional pipe replacement?

Relining offers several advantages over traditional pipe replacement, including:

- Less disruption: Relining can be done without digging up the pipe, which minimizes disruption to traffic and businesses.

- Faster installation: Relining can be completed in a matter of days, compared to weeks or months for traditional pipe replacement.

- Lower cost: Relining is typically less expensive than traditional pipe replacement.

- Extended lifespan: Relined pipes can last for decades, extending the life of the existing infrastructure.

4. What are the challenges of relining?

Some of the challenges associated with relining include:

- Proper site preparation: The existing pipe must be properly cleaned and prepared before the liner can be installed.

- Access to the pipe: Relining can be difficult if the pipe is located in a tight or confined space.

- Quality control: It is important to ensure that the liner is properly installed and cured to prevent leaks or failures.

- Long-term performance: The long-term performance of a relined pipe depends on the quality of the materials and installation.

5. What are the latest trends in relining technology?

Some of the latest trends in relining technology include:

- The use of robotics: Robots can be used to inspect pipes and install liners, making the process more efficient and cost-effective.

- The development of new materials: New materials are being developed that are more durable, flexible, and resistant to corrosion.

- The use of trenchless techniques: Trenchless techniques are being developed that allow relining to be done without digging up the pipe.

- The development of predictive analytics: Predictive analytics can be used to identify pipes that are at risk of failure, allowing relining to be done before a problem occurs.

6. What is the future of relining?

Relining is expected to become increasingly popular in the future as a cost-effective and environmentally friendly way to rehabilitate aging infrastructure.

- The development of new technologies: The development of new technologies will make relining more efficient, cost-effective, and reliable.

- The increasing demand for infrastructure rehabilitation: The aging infrastructure in many countries will create a growing demand for relining services.

- The increasing awareness of the environmental benefits of relining: Relining is a more environmentally friendly alternative to traditional pipe replacement, as it reduces the amount of waste generated and the disruption to the environment.

7. How do you stay up-to-date on the latest relining technology?

I stay up-to-date on the latest relining technology by:

- Attending industry conferences and trade shows

- Reading technical journals and articles

- Networking with other professionals in the field

- Taking continuing education courses

8. What is your experience with relining projects?

I have worked on a variety of relining projects, including:

- Rehabilitation of a 24-inch water main using CIPP

- Installation of a slip lining in a 12-inch sewer pipe

- Spray lining of a 6-inch gas pipeline

- Roll-down lining of a 4-inch oil pipeline

9. What is your favorite type of relining project?

My favorite type of relining project is one that is challenging and requires a creative solution.

- I enjoy working on projects that involve the rehabilitation of historic pipes

- I also enjoy working on projects that involve the use of new and innovative technologies.

10. What is the most important thing to remember when relining a pipe?

The most important thing to remember when relining a pipe is to:

- Properly prepare the existing pipe

- Select the right relining material and installation method

- Follow the manufacturer’s instructions carefully

- Inspect the relined pipe thoroughly before putting it back into service

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Reliner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Reliner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Reliner is responsible for restoring, repairing, and relining the interior of pipes, tanks, and other structures.

1. Inspection and Assessment

Conduct thorough inspections to determine the condition of pipes, tanks, and other structures, identifying any damage or areas requiring repair.

- Use specialized equipment, such as cameras and ultrasonic testing devices, to assess the extent and severity of damage.

- Prepare detailed reports outlining the findings and recommend appropriate repair or relining solutions.

2. Surface Preparation

Clean and prepare the surfaces of pipes, tanks, or other structures prior to relining.

- Remove rust, scale, and debris using abrasive blasting, chemical cleaning, or other techniques.

- Ensure the surfaces are smooth and free of contaminants to ensure proper adhesion of the relining material.

3. Relining

Apply the relining material to the interior of the structure using various techniques.

- Mix and apply resin-based or epoxy-based materials using specialized spray or trowel techniques.

- Ensure the relining material is evenly distributed and cures properly to provide a durable and corrosion-resistant coating.

4. Curing and Inspection

Monitor the curing process of the relining material and conduct final inspections.

- Ensure the relining material has fully cured and adheres firmly to the surfaces.

- Perform visual and non-destructive testing to verify the integrity and quality of the relining.

Interview Tips

Preparing thoroughly for a relining interview is crucial for success. Here are some effective tips to help you ace your interview:

1. Research the Company and Position

Familiarize yourself with the company’s website, social media profiles, and industry news to understand their mission, values, and recent projects.

- Identify the specific requirements of the reliner position and tailor your resume and interview responses accordingly.

- Prepare questions about the company’s relining processes, safety protocols, and growth opportunities.

2. Practice Your Answers

Anticipate common interview questions and prepare concise, well-thought-out answers that highlight your skills and experience.

- Use the STAR method (Situation, Task, Action, Result) to provide specific examples of your relining work.

- Quantify your accomplishments whenever possible to demonstrate the impact of your efforts.

3. Showcase Your Technical Expertise

Emphasize your knowledge of relining materials, techniques, and industry standards.

- Discuss your experience with different types of relining projects, including pipe lining, tank lining, and manhole rehabilitation.

- Highlight your understanding of safety protocols and quality control measures.

4. Highlight Your Communication Skills

Reliners often interact with clients, engineers, and contractors. Demonstrate your ability to communicate effectively.

- Explain how you convey technical information to non-technical stakeholders.

- Provide examples of how you resolved conflicts and maintained positive relationships on project sites.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Reliner interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.