Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Formstone Fitter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

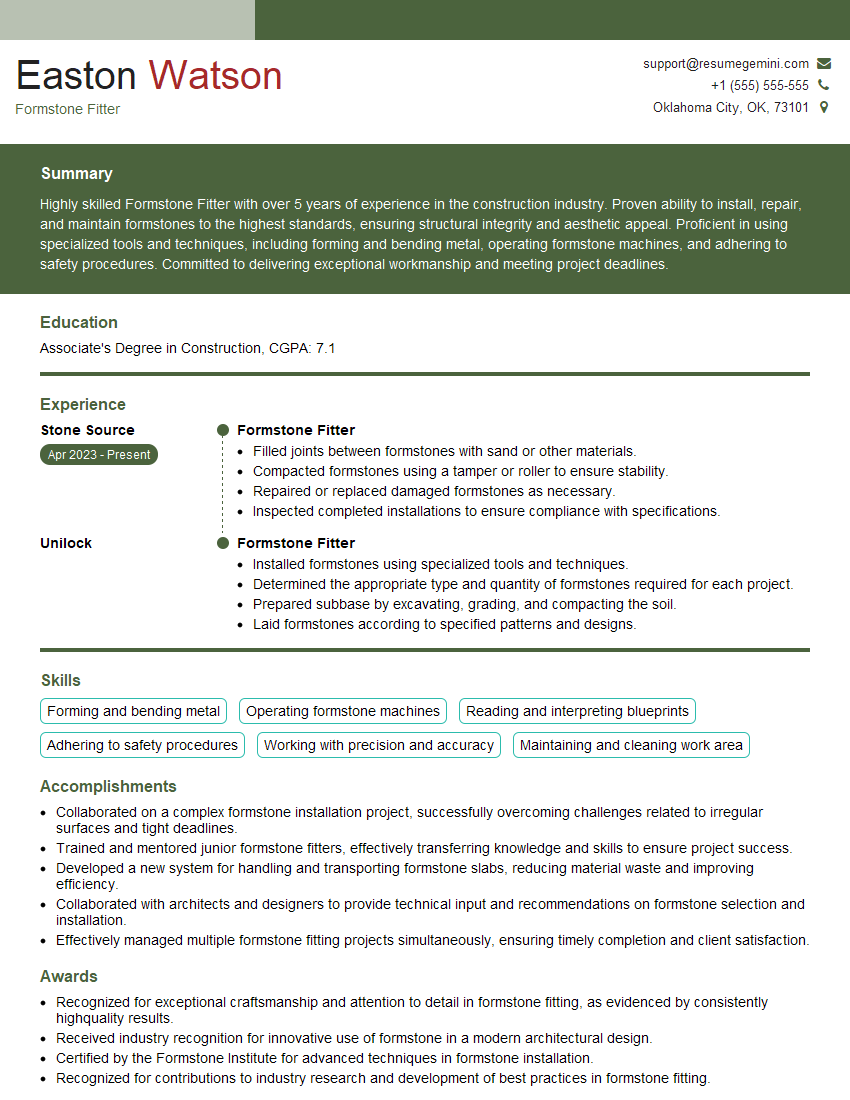

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Formstone Fitter

1. What are the different types of formstone available and their key characteristics?

There are several types of formstone available, including:

- Natural stone: This type of formstone is made from quarried stone, and it offers the most natural appearance. Natural stone is durable and long-lasting, but it can also be more expensive than other types of formstone.

- Manufactured stone: This type of formstone is made from a combination of cement, sand, and aggregates. It is less expensive than natural stone, and it is available in a wide range of colors and textures.

- Polystyrene formstone: This type of formstone is made from expanded polystyrene, and it is the most lightweight and affordable option. Polystyrene formstone is not as durable as natural or manufactured stone, but it is easy to install and can be painted or stained to match any décor.

2. Can you explain the key steps involved in installing formstone?

Preparation

- Inspect the surface to be covered and make sure it is level and free of debris.

- Apply a bonding agent to the surface.

- Lay out the formstone pieces to determine the best placement.

Installation

- Apply a layer of mortar to the back of the formstone piece.

- Set the formstone piece in place and press it firmly into the mortar.

- Repeat this process until all of the formstone pieces are installed.

Finishing

- Allow the mortar to cure for 24 hours.

- Grout the joints between the formstone pieces.

- Seal the formstone to protect it from the elements.

3. What are some common mistakes to avoid when installing formstone?

- Not preparing the surface properly.

- Not using the right type of mortar.

- Not setting the formstone pieces in the mortar properly.

- Not grouting the joints properly.

- Not sealing the formstone properly.

4. What are the advantages and disadvantages of using formstone over other types of cladding materials?

Advantages

- Durability

- Versatility

- Affordability

- Ease of installation

Disadvantages

- Weight

- Can be difficult to repair

- Not as fire-resistant as some other materials

5. What safety precautions should be taken when working with formstone?

- Wear gloves and safety glasses.

- Use a dust mask when cutting or grinding formstone.

- Be aware of the weight of the formstone pieces and lift them carefully.

- Use a ladder or scaffolding when working on elevated surfaces.

- Follow all manufacturer’s instructions for the safe use of formstone.

6. What are some tips for cutting formstone?

- Use a wet saw with a diamond blade.

- Score the formstone piece before cutting it to help prevent chipping.

- Use a straight edge to guide the saw.

- Wear gloves and safety glasses when cutting formstone.

7. What are some tips for grouting formstone?

- Use a grout that is specifically designed for formstone.

- Mix the grout according to the manufacturer’s instructions.

- Apply the grout to the joints between the formstone pieces using a grout float.

- Wipe away any excess grout with a damp sponge.

- Allow the grout to cure for 24 hours before sealing it.

8. What are some tips for sealing formstone?

- Use a sealer that is specifically designed for formstone.

- Apply the sealer according to the manufacturer’s instructions.

- Allow the sealer to dry completely before using the formstone surface.

- Reseal the formstone surface every 2-3 years to maintain its protection.

9. What are some common problems that can occur with formstone and how can they be fixed?

Problem: Efflorescence

- Cause: Moisture seeping through the formstone and carrying salts to the surface.

- Solution: Remove the efflorescence with a wire brush or a mild acid solution.

Problem: Staining

- Cause: Dirt, mildew, or other contaminants accumulating on the formstone surface.

- Solution: Clean the formstone surface with a mild detergent or a bleach solution.

Problem: Chipping

- Cause: Impact from objects or improper installation.

- Solution: Repair the chipped area with a patching compound or a piece of matching formstone.

10. What are the key qualities of a successful formstone fitter?

- Attention to detail

- Strong work ethic

- Physical fitness

- Ability to work independently and as part of a team

- Excellent communication skills

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Formstone Fitter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Formstone Fitter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Formstone Fitters are skilled tradespeople responsible for installing and maintaining formstone on buildings and other structures. They work with various types of formstone, including precast concrete, artificial stone, and natural stone. Formstone Fitters must have a strong understanding of construction principles and be able to work independently and as part of a team.

1. Installing Formstone

Formstone Fitters typically follow these steps to install formstone:

- Prepare the surface by cleaning and leveling it.

- Apply a layer of mortar or adhesive to the surface.

- Set the formstone in place and press it into the mortar or adhesive.

- Grout the joints between the formstone pieces.

2. Maintaining Formstone

Formstone Fitters may also be responsible for maintaining formstone. This may include:

- Inspecting formstone for damage.

- Repairing damaged formstone.

- Cleaning formstone.

3. Other Duties

In addition to installing and maintaining formstone, Formstone Fitters may also perform other duties, such as:

- Estimating the cost of formstone projects.

- Ordering materials.

- Supervising other workers.

Interview Tips

Here are some tips to help you ace your interview for a Formstone Fitter position:

1. Research the Company and the Position

Before you go on an interview, it is important to research the company and the position you are applying for. This will help you understand the company’s culture and values, as well as the specific requirements of the job. You can research the company’s website, read articles about the company, and talk to people who work there.

- Research common interview questions and practice your answers.

- Be prepared to talk about your experience and skills.

- Dress professionally and arrive on time for your interview.

2. Highlight Your Skills and Experience

In your interview, be sure to highlight your skills and experience that are relevant to the Formstone Fitter position. For example, you can talk about your experience installing and maintaining formstone, as well as your knowledge of construction principles. You can also mention any other skills or experience that would make you a valuable asset to the company.

- Be enthusiastic and positive about the job.

- Ask questions about the company and the position.

- Follow up with the interviewer after the interview.

3. Be Prepared to Answer Questions

During your interview, you will likely be asked a variety of questions about your skills, experience, and qualifications. Be prepared to answer these questions in a clear and concise manner. Some common interview questions include:

- Tell me about your experience installing and maintaining formstone.

- What are your strengths and weaknesses as a Formstone Fitter?

- Why are you interested in working for our company?

4. Ask Questions

At the end of your interview, be sure to ask the interviewer any questions you have about the company or the position. This shows that you are interested in the job and that you are taking the interview seriously. Some good questions to ask include:

- What are the biggest challenges facing the company right now?

- What are the opportunities for advancement within the company?

- What is the company culture like?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Formstone Fitter interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.