Are you gearing up for a career in Stone Mason? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Stone Mason and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

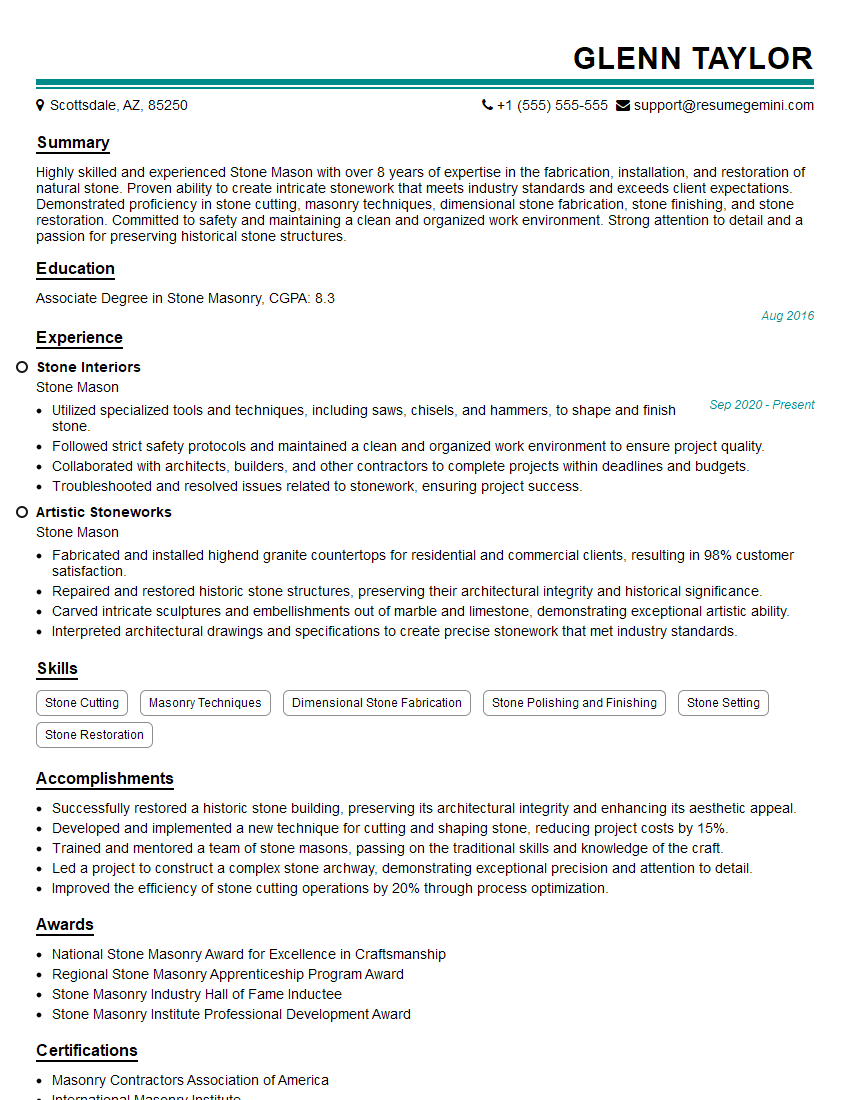

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Stone Mason

1. Describe the process of preparing a stone surface for laying?

To prepare a stone surface for laying, I follow these steps:

- Inspect the surface: I check for any unevenness, cracks, or other imperfections that need to be addressed.

- Clean the surface: I thoroughly clean the surface using a pressure washer or a stiff-bristled brush to remove dirt, debris, and any loose particles.

- Level the surface: If necessary, I level the surface using a screed or a leveling compound to create a smooth and even base.

- Apply a bonding agent: I apply a bonding agent to the surface to improve the adhesion between the stone and the underlying substrate.

2. What are the different types of stone finishes and how do you achieve them?

Polished Finish

- Using diamond-abrasive pads or polishing wheels, I grind and polish the stone surface to create a smooth, glossy finish that reflects light.

Honed Finish

- Instead of polishing, I use abrasive pads or stones to create a smooth but matte finish that has a soft, velvety texture.

Flamed Finish

- I subject the stone surface to a high-temperature flame, which causes the surface to become rough and textured.

Brushed Finish

- Using a wire brush or a rotary hammer with a brush attachment, I create a textured finish with visible brush strokes.

3. How do you handle and transport large and heavy stone slabs safely?

To safely handle and transport large and heavy stone slabs, I take the following precautions:

- Use proper equipment: I employ lifting straps, dollies, and cranes to move the slabs without causing damage or injury.

- Secure the slabs: I use straps or ropes to secure the slabs securely to the lifting equipment to prevent them from shifting or falling.

- Protect the slabs: I wrap the slabs in protective materials, such as blankets or foam, to prevent scratches or damage during transportation.

- Plan the route: I carefully plan the transportation route to avoid obstacles and ensure the safe passage of the slabs.

4. What are the common mistakes to avoid when cutting and shaping stone?

To avoid common mistakes when cutting and shaping stone, I pay attention to the following:

- Using the wrong tools: I ensure I have the appropriate cutting and shaping tools for the type of stone I’m working with.

- Not securing the stone properly: I secure the stone firmly in place before cutting or shaping to prevent movement and ensure precision.

- Applying excessive force: I avoid using excessive force when cutting or shaping the stone, as this can lead to cracks or breakage.

- Ignoring the grain: I pay attention to the grain direction of the stone and cut or shape accordingly to avoid splitting or weakening the stone.

5. How do you ensure the accuracy and precision of stone cutting and shaping?

To ensure accuracy and precision when cutting and shaping stone, I follow these practices:

- Use templates and guides: I create templates or use measuring tools and guides to mark precise cutting and shaping lines.

- Measure twice, cut once: I double-check all measurements before making any cuts or shaping to minimize errors.

- Use sharp tools: I maintain sharp cutting and shaping tools to ensure clean and precise cuts and shaping.

- Test cuts and adjustments: I make small test cuts or adjustments to refine the accuracy and precision of the final product.

6. What are the safety precautions to observe when working with stone cutting and shaping equipment?

When working with stone cutting and shaping equipment, I prioritize the following safety precautions:

- Wear protective gear: I wear safety glasses, a dust mask, and gloves to protect myself from flying debris and dust.

- Guard machinery: I ensure that all machinery is properly guarded to prevent accidental contact with moving parts.

- Secure equipment: I securely fasten equipment to stable surfaces to prevent movement or vibration.

- Maintain equipment: I regularly inspect and maintain equipment to ensure it’s in good working condition.

7. How do you repair and restore damaged stone surfaces?

To repair and restore damaged stone surfaces, I employ the following techniques:

- Identify the damage: I assess the extent and type of damage to determine the appropriate repair method.

- Clean the surface: I thoroughly clean the damaged area to remove dirt and debris.

- Fill cracks and holes: I use epoxy or stone filler to fill cracks and holes, ensuring a seamless repair.

- Re-polish or re-texture the surface: I re-polish or re-texture the repaired area to match the surrounding surface.

8. What are the different types of stone sealers and how do you choose the right one?

Penetrating Sealers

- These sealers penetrate the stone’s pores to create a barrier against moisture and stains.

Surface Sealers

- These sealers form a protective layer on the surface of the stone to repel water and other liquids.

Impregnating Sealers

- These sealers combine the properties of penetrating and surface sealers, offering both penetration and surface protection.

I choose the right sealer based on the type of stone, its porosity, and the desired level of protection.

9. How do you calculate the amount of stone required for a project?

To calculate the amount of stone required for a project, I:

- Measure the area to be covered: I determine the length and width of the area to calculate the square footage.

- Consider the thickness of the stone: I multiply the square footage by the desired thickness of the stone to get the cubic footage.

- Add a buffer: I add an additional 5-10% to account for waste and breakage.

10. What are the factors to consider when selecting the right stone for a specific application?

When selecting the right stone for a specific application, I consider the following factors:

- Type of application: I determine whether the stone will be used for flooring, countertops, walls, or other purposes.

- Durability and hardness: I assess the foot traffic, wear and tear, and potential impact the stone will be subjected to.

- Resistance to moisture and staining: I consider the potential exposure to water, chemicals, or other staining agents.

- Aesthetics: I match the color, texture, and finish of the stone to the desired design and style.

- Cost and availability: I consider the budget and the availability of the stone in the desired quantity and quality.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Stone Mason.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Stone Mason‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Stone Masons are skilled craftsmen who specialize in the shaping, cutting, and assembling of natural stone. They work on projects of all sizes, from small repairs to large-scale construction.

1. Cutting and Shaping Stone

Stone Masons use a variety of tools to cut and shape stone, including chisels, hammers, and saws. They must be able to accurately follow blueprints and specifications.

- Cut and shape natural stone using hand and power tools

- Follow blueprints and specifications to ensure accuracy

2. Assembling Stone

Once the stone has been cut and shaped, Stone Masons assemble it using mortar or other adhesives. They must ensure that the stones are properly aligned and level.

- Assemble stone using mortar or other adhesives

- Ensure that stones are properly aligned and level

3. Finishing Stone

The final step in the process is to finish the stone. This may involve grinding, polishing, or carving the stone to achieve the desired look.

- Grind, polish, or carve stone to achieve desired look

- Clean and seal stone to protect it from the elements

4. Other Duties

In addition to the above responsibilities, Stone Masons may also be required to:

- Operate heavy machinery

- Load and unload materials

- Clean up work area

Interview Tips

Preparing for an interview can be a daunting task, but there are a few things you can do to increase your chances of success. Follow these tips to help you ace your interview for a Stone Mason position:

1. Research the Company and the Position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and values, as well as the specific requirements of the job.

- Visit the company’s website

- Read articles about the company and its industry

- Talk to people who work for the company

2. Practice Your Answers to Common Interview Questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Take some time to practice your answers to these questions so that you can deliver them confidently and concisely.

- Use the STAR method to answer interview questions

- Practice your answers with a friend or family member

- Time yourself to make sure your answers are concise

3. Dress Professionally

First impressions matter, so make sure you dress professionally for your interview. This means wearing a suit or business casual attire. You should also make sure your clothes are clean and pressed.

- Wear a suit or business casual attire

- Make sure your clothes are clean and pressed

- Avoid wearing strong perfumes or colognes

4. Be Yourself

It is important to be yourself during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Just relax and be yourself, and the interviewer will be able to see your true potential.

- Be honest and authentic in your answers

- Show the interviewer your personality

- Don’t be afraid to ask questions

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Stone Mason, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Stone Mason positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.