Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Cabinetmaker interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Cabinetmaker so you can tailor your answers to impress potential employers.

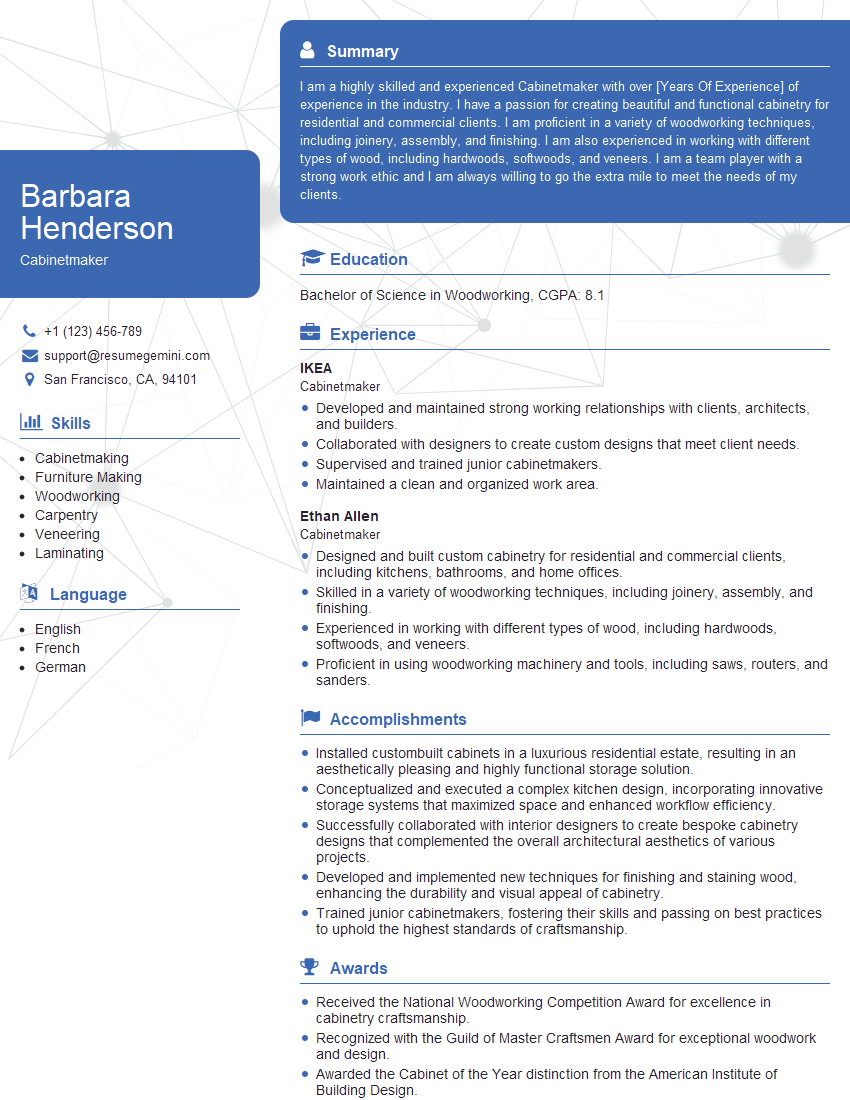

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cabinetmaker

1. What are the different types of wood joints used in cabinetmaking?

- Mitre joint: Used to join two pieces of wood at a 45-degree angle, commonly used in picture frames and moldings.

- Mortise and tenon joint: Creates a strong and durable connection between two pieces of wood, where a mortise (hole) is cut into one piece and a tenon (projection) is cut into the other, allowing them to fit together securely.

- Dovetail joint: A highly durable joint used for drawers and boxes, where interlocking pins and tails are cut into the edges of two pieces of wood, creating a strong and attractive connection.

- Rabbet joint: A joint where one piece of wood has a groove or recess cut into it, and the other piece has a matching tongue or projection that fits into the groove, commonly used for attaching shelves or panels to cabinet frames.

- Biscuit joint: Uses small oval-shaped wooden biscuits to align and join two pieces of wood, providing a strong and concealed connection.

2. What are the essential power tools used in cabinetmaking?

- Table saw: For cutting straight lines, ripping, and crosscutting.

- Miter saw: For making precise angle cuts.

- Drill press: For drilling precise holes.

- Router: For cutting decorative edges, dados, and grooves.

- Sander: For smoothing surfaces and removing imperfections.

- Planer: For leveling and thickening wood.

- Jointer: For straightening edges and flattening surfaces.

3. What is the process of veneering?

- Preparation: Selecting and preparing the substrate and veneer.

- Application: Applying adhesive to the substrate and veneer, then aligning and pressing them together.

- Trimming: Removing excess veneer around the edges.

- Sanding: Smoothing the surface and removing any imperfections.

- Finishing: Applying protective coatings such as stains, sealers, or topcoats.

4. What are the different types of finishing techniques used in cabinetmaking?

- Staining: Applying a pigmented liquid to color and enhance the natural grain of the wood.

- Sealing: Applying a clear finish to protect the wood from moisture and wear.

- Topcoating: Applying a durable finish such as polyurethane, lacquer, or varnish to provide additional protection and sheen.

- Glazing: Applying a semi-transparent glaze to create depth and dimension.

- Aging: Using techniques like distressing or antiquing to give the finished product a vintage or weathered look.

5. What are the important safety precautions to observe in a cabinetmaking workshop?

- Wear appropriate safety gear: Including safety glasses, earplugs, and a dust mask.

- Keep the workspace clean and organized: To prevent tripping or slipping.

- Ensure proper ventilation: To remove toxic fumes and dust.

- Operate power tools safely: By following manufacturer instructions and using guards and safety devices.

- Handle materials carefully: To avoid cuts, splinters, or other injuries.

- Be aware of electrical hazards: By using grounded equipment and avoiding frayed wires.

6. What is the importance of moisture content in wood?

- Dimensional stability: Moisture content affects the size and shape of wood, as it expands when it absorbs moisture and contracts when it dries out. Controlling moisture content helps maintain the desired dimensions of cabinets.

- Warpage: Uneven moisture distribution can cause wood to warp, making it difficult to assemble cabinets properly.

- Fungal growth: High moisture content can create a favorable environment for mold and mildew growth, damaging the wood and potentially affecting indoor air quality.

- Adhesive performance: Moisture content can affect the adhesion of glues and other bonding agents, impacting the strength of joints.

- Finishing: Moisture content can influence the application and performance of finishes, affecting their durability and appearance.

7. What are the key factors to consider when designing a kitchen layout?

- Work triangle: Ensuring efficient movement between the refrigerator, sink, and stove.

- Storage needs: Planning adequate storage space to accommodate kitchen supplies, appliances, and food.

- Appliance placement: Considering the size, functionality, and ventilation requirements of appliances.

- Lighting: Designing a lighting plan that provides adequate illumination for tasks and creates a desired ambiance.

- Ergonomics: Designing the layout to minimize strain and promote comfort while working in the kitchen.

- Aesthetic considerations: Matching the design style and finishes to the overall home decor.

8. What is the role of computer-aided design (CAD) in cabinetmaking?

- Design accuracy: CAD software enables precise design and visualization, minimizing errors and ensuring a high level of accuracy.

- Efficiency: CAD tools streamline the design process, allowing for faster creation and modification of plans.

- Collaboration: CAD files can be easily shared and reviewed, facilitating collaboration between designers, clients, and manufacturers.

- Material optimization: CAD software can help optimize material usage, reducing waste and costs.

- Virtual rendering: CAD programs allow for realistic visualization of designs, enabling clients to preview the finished product before production.

9. How do you ensure the quality of your cabinetmaking work?

- Attention to detail: Paying meticulous attention to each aspect of the design and construction process.

- Quality materials: Using high-quality wood, hardware, and other materials that meet industry standards.

- Proper techniques: Employing proven techniques and best practices to ensure durability and precision.

- Quality control: Implementing quality control measures at every stage of production, including inspections and testing.

- Customer feedback: Valuing customer feedback and using it to continuously improve products and services.

10. Why are you interested in working as a cabinetmaker in our company?

- Reputation: Expressing admiration for the company’s reputation for excellence in cabinetmaking.

- Values: Aligning with the company’s values of quality, craftsmanship, and customer satisfaction.

- Growth opportunities: Seeing the potential for professional growth and development within the company.

- Teamwork: Emphasizing a collaborative and team-oriented approach to work.

- Contribution: Expressing enthusiasm for contributing to the company’s success through high-quality craftsmanship.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cabinetmaker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cabinetmaker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cabinetmakers are responsible for creating custom-built wooden cabinets and furniture. They use a variety of tools and techniques to create high-quality products.

1. Design and Planning

They work with clients to design and plan custom-built cabinets and furniture. They need to understand the client’s needs and preferences and be able to translate them into a working design.

- Meeting with clients to discuss their needs and preferences

- Creating design plans and specifications

2. Build and Assemble

They build and assemble cabinets and furniture using a variety of tools and techniques. They need to be proficient in the use of power tools and equipment.

- Cutting and shaping wood

- Assembling cabinets and furniture

- Installing hardware and finishes

3. Finishing

They apply finishes to cabinets and furniture to protect them and improve their appearance. They need to be familiar with different types of finishes and how to apply them.

- Sanding and smoothing surfaces

- Applying stains and finishes

4. Installation

They install cabinets and furniture in homes and businesses. They need to be able to work independently and follow instructions carefully.

- Installing cabinets and furniture in homes and businesses

- Ensuring that cabinets and furniture are installed properly

Interview Tips

Preparing for a cabinetmaker interview can be daunting, but with the right tips and strategies, you can increase your chances of success. Here are a few tips to help you ace your interview:

1. Research the Company

Researching the company before your interview shows that you are interested in the position and the company itself. This will also help you to answer questions about the company’s history, mission, and values.

- Visit the company’s website

- Read the company’s blog and social media pages

2. Practice Your Answers

Take some time to practice answering common interview questions. This will help you to feel more confident and prepared during the interview. Some common questions you may be asked include:

- Tell me about your experience as a cabinetmaker.

- What are your strengths and weaknesses as a cabinetmaker?

- Why are you interested in working for this company?

- What are your salary expectations?

3. Dress Professionally

First impressions matter, so make sure to dress professionally for your interview. This means wearing clean, pressed clothing that is appropriate for the office environment.

- Wear a suit or dress pants and a button-down shirt

- Make sure your shoes are clean and polished

4. Be Prepared to Show Your Portfolio

If you have a portfolio of your work, be prepared to share it with the interviewer. This is a great way to showcase your skills and experience.

- Include examples of your best work

- Be able to discuss the details of your projects

5. Ask Questions

Asking questions at the end of the interview shows that you are interested in the position and the company. It also gives you an opportunity to learn more about the company and the position.

- Ask about the company’s culture

- Ask about the company’s training and development programs

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cabinetmaker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.