Feeling lost in a sea of interview questions? Landed that dream interview for Mold Carpenter but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Mold Carpenter interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

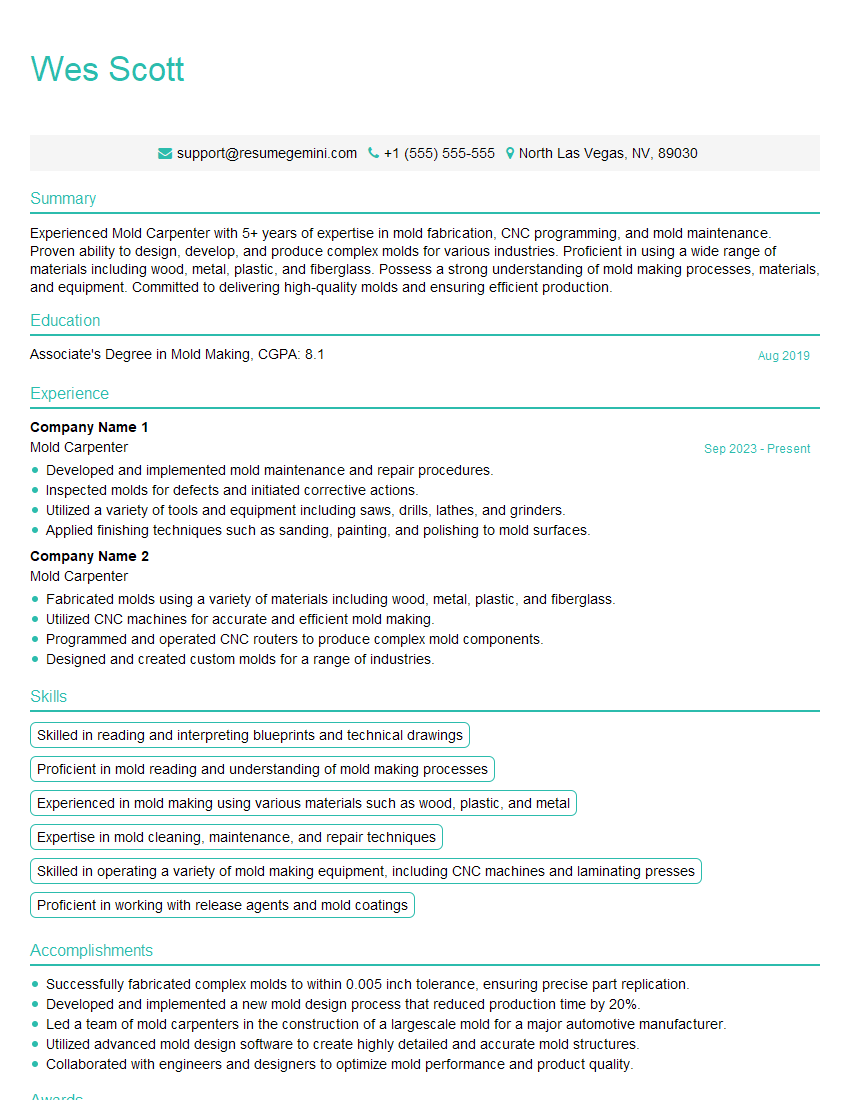

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Mold Carpenter

1. What are the different types of molds used in carpentry?

- Core box

- Drag

- Cope

- Pattern

- Flask

2. Describe the process of molding and casting using a sand mold.

Pattern making

- Create a pattern of the desired casting.

- The pattern is made of wood or metal.

Mold making

- Pack sand around the pattern to create a mold.

- The mold is then separated into two halves.

Casting

- Molten metal is poured into the mold.

- The metal solidifies and takes the shape of the mold.

3. What are the different materials used for making molds?

- Sand

- Metal

- Plastic

- Rubber

- Silicone

4. What are the key factors to consider when designing a mold?

- The geometry of the part being cast

- The material being cast

- The casting process

- The cost of the mold

5. What are the different techniques used to repair molds?

- Patching

- Welding

- Casting

6. What are the safety precautions that must be taken when working with molds?

- Wear protective clothing

- Use ventilation

- Handle molds with care

- Dispose of molds properly

7. What are the different types of mold release agents used in carpentry?

- Wax

- Oil

- Silicone

- Powder

8. How do you calculate the shrinkage allowance for a casting?

- The shrinkage allowance is the amount of material that will shrink during cooling.

- The shrinkage allowance is calculated by multiplying the length of the casting by the shrinkage factor for the material being cast.

9. What are the different types of casting defects?

- Shrinkage cavities

- Gas porosity

- Sand inclusions

- Cold shuts

- Misruns

10. How do you prevent casting defects?

- Use a proper gating system

- Control the pouring temperature

- Use a mold release agent

- Allow the casting to cool slowly

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Mold Carpenter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Mold Carpenter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Mold Carpenters are highly skilled craftspeople who specialize in creating molds and patterns used in various industries, including manufacturing, construction, and design. Their primary responsibilities include:

1. Mold Making

Design and construct molds using materials such as wood, metal, plastic, or composite materials.

- Interpret blueprints and specifications to create molds that meet precise dimensions and tolerances.

- Select and use appropriate materials and techniques to ensure mold durability and accuracy.

2. Pattern Making

Create patterns for casting or forming products. These patterns serve as guides for shaping materials.

- Develop patterns based on designs and specifications.

- Cut, shape, and assemble pattern components with precision.

3. Equipment Operation

Operate and maintain specialized machinery, such as routers, CNC machines, and grinders.

- Use computer-aided design (CAD) software to create and modify molds and patterns.

- Ensure equipment is calibrated and functioning correctly.

4. Quality Control

Inspect molds and patterns to ensure they meet specifications and quality standards.

- Use measuring tools and gauges to verify dimensions and tolerances.

- Identify and correct defects or inaccuracies.

Interview Tips

Preparing for a Mold Carpenter interview requires careful planning and research. Here are some tips to help you ace the interview:

1. Research the Company and Position

Thoroughly research the company, its products or services, and the specific role you’re applying for.

- Visit the company’s website and social media pages.

- Read industry publications and news articles to stay informed about the company and the sector.

2. Highlight Your Skills and Experience

Tailor your resume and cover letter to emphasize the skills and experience most relevant to the position.

- Quantify your accomplishments and provide specific examples of your contributions.

- Use industry-specific terminology and demonstrate your knowledge of mold making and pattern making techniques.

3. Prepare for Technical Questions

Expect technical questions related to mold making, pattern making, and equipment operation.

- Review basic principles of mold design, materials, and construction.

- Practice answering questions about your experience with different types of equipment and software.

4. Practice Your Presentation

Prepare answers to common interview questions, such as “Tell me about yourself” or “Why are you interested in this position?”

- Rehearse your answers aloud to improve your delivery and confidence.

- Seek feedback from a mentor or career counselor to refine your presentation.

5. Dress Professionally and Arrive Punctually

First impressions matter. Dress professionally and arrive at the interview on time.

- Consider wearing business attire or clothes that are appropriate for the company culture.

- Plan your route beforehand to avoid any delays or mishaps.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Mold Carpenter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!