Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Railcar Carpenter interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Railcar Carpenter so you can tailor your answers to impress potential employers.

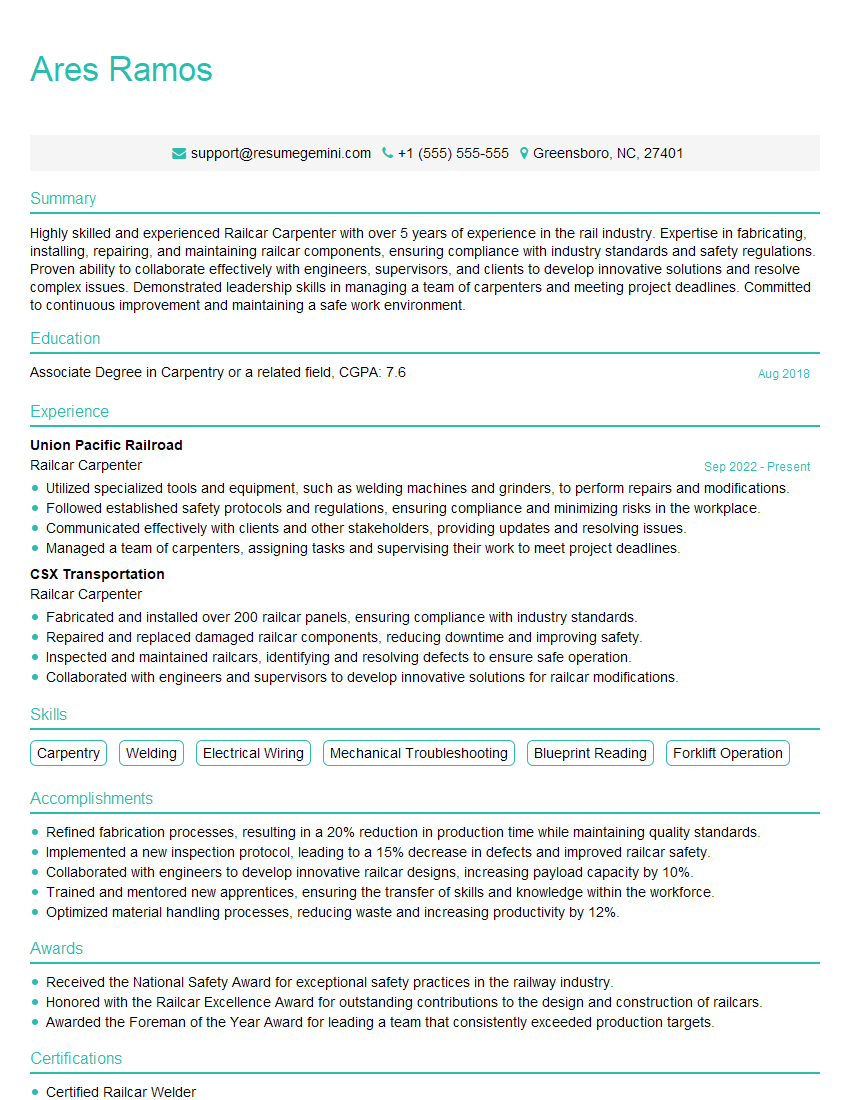

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Railcar Carpenter

1. Describe the process of replacing a damaged railcar side sill?

The process of replacing a damaged railcar side sill typically involves the following steps:

- Secure the railcar and discharge any stored energy.

- Unload the railcar and remove any hazardous materials.

- Disconnect the damaged side sill from the rest of the railcar.

- Cut out the damaged section of the side sill.

- Fabricate and install a new section of side sill.

- Weld the new section of side sill into place.

- Inspect the repair and ensure that it meets all safety standards.

- Perform a pressure test to ensure that the repair is leak-free.

2. What types of welding techniques are used in railcar repair, and when would you use each type?

MIG welding:

- Used for welding mild steel and stainless steel.

- Produces a high-quality weld with minimal spatter.

- Can be used in all positions.

TIG welding:

- Used for welding thin metals and exotic materials.

- Produces a high-quality weld with no spatter.

- Can only be used in the flat and horizontal positions.

Stick welding:

- Used for welding thick metals and in outdoor applications.

- Produces a less-quality weld with more spatter.

- Can be used in all positions.

3. Explain the importance of proper railcar inspection and maintenance.

Proper railcar inspection and maintenance are important for the following reasons:

- To ensure the safety of the railcar and its occupants.

- To prevent breakdowns and delays.

- To extend the life of the railcar.

4. Describe the different types of railcar brake systems, and how each type works.

Air brakes:

- The most common type of railcar brake system.

- Uses compressed air to actuate the brake shoes.

- Provides a gradual and controlled braking action.

Hydraulic brakes:

- Less common than air brakes.

- Uses hydraulic fluid to actuate the brake shoes.

- Provides a more powerful braking action than air brakes.

Electric brakes:

- The newest type of railcar brake system.

- Uses electricity to actuate the brake shoes.

- Provides the most precise and controlled braking action.

5. What are the most common causes of railcar derailments, and how can they be prevented?

The most common causes of railcar derailments are:

- Track defects

- Equipment failures

- Human error

Derailments can be prevented by:

- Maintaining the track in good condition.

- Using reliable equipment.

- Training railcar operators properly.

6. What are the different types of railcar couplers, and what are the advantages and disadvantages of each type?

The different types of railcar couplers are:

- Janney coupler

- Knuckle coupler

- Automatic coupler

The advantages and disadvantages of each type are:

- Janney coupler: Simple and reliable, but not as strong as other types of couplers.

- Knuckle coupler: Stronger than the Janney coupler, but more complex and expensive.

- Automatic coupler: The most modern type of coupler, which is easy to use and very strong.

7. What are the different types of railcar trucks, and what are the advantages and disadvantages of each type?

The different types of railcar trucks are:

- Two-axle trucks

- Three-axle trucks

- Four-axle trucks

The advantages and disadvantages of each type are:

- Two-axle trucks: Less expensive and easier to maintain than other types of trucks, but not as stable.

- Three-axle trucks: More stable than two-axle trucks, but more expensive and difficult to maintain.

- Four-axle trucks: The most stable type of truck, but the most expensive and difficult to maintain.

8. What are the different types of railcar wheels, and what are the advantages and disadvantages of each type?

The different types of railcar wheels are:

- Cast iron wheels

- Steel wheels

- Composite wheels

The advantages and disadvantages of each type are:

- Cast iron wheels: Less expensive than other types of wheels, but not as durable.

- Steel wheels: More durable than cast iron wheels, but more expensive.

- Composite wheels: The most durable type of wheel, but the most expensive.

9. What are the different types of railcar bearings, and what are the advantages and disadvantages of each type?

The different types of railcar bearings are:

- Plain bearings

- Roller bearings

- Ball bearings

The advantages and disadvantages of each type are:

- Plain bearings: Less expensive than other types of bearings, but not as durable.

- Roller bearings: More durable than plain bearings, but more expensive.

- Ball bearings: The most durable type of bearing, but the most expensive.

10. What are the different types of railcar suspension systems, and what are the advantages and disadvantages of each type?

The different types of railcar suspension systems are:

- Leaf spring suspension

- Coil spring suspension

- Air spring suspension

The advantages and disadvantages of each type are:

- Leaf spring suspension: Less expensive than other types of suspension systems, but not as comfortable.

- Coil spring suspension: More comfortable than leaf spring suspension, but more expensive.

- Air spring suspension: The most comfortable type of suspension system, but the most expensive.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Railcar Carpenter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Railcar Carpenter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Railcar Carpenters are responsible for maintaining, constructing, and repairing railroad cars, as well as for operating power tools and heavy machinery in the process. They may also be tasked with assisting in the design and fabrication of railroad cars.

1. Inspect and Repair Railcars

Inspect and repair all types of railcars, including freight cars, passenger cars, and specialized cars.

- Identify and diagnose the cause of any damage or malfunctioning.

- Repair or replace damaged or worn components, such as wheels, brakes, couplers, and doors.

- Test and ensure that repaired railcars meet safety and operational standards.

2. Construct and Fabricate Railcars

Construct and fabricate new railcars or components of railcars, following blueprints and specifications.

- Cut, shape, weld, and assemble metal components.

- Install electrical, mechanical, and plumbing systems, ensuring proper function.

- Inspect and test completed railcars to ensure that they meet specifications.

3. Maintain and Inspect Railcar Equipment

Maintain and inspect tools and equipment used in the construction, maintenance, and repair of railcars.

- Clean, lubricate, and adjust tools and equipment regularly.

- Identify and report any maintenance or repair needs.

4. Safety Responsibilities

Adhere to all safety regulations and protocols, including working at heights, handling hazardous materials, and operating heavy machinery.

- Wear appropriate safety gear, such as hard hats, safety glasses, and gloves.

- Practice safe work practices and maintain a clean and organized work area.

- Report any accidents, injuries, or unsafe conditions.

Interview Tips

Preparing for an interview can be daunting, but with the right approach, you can increase your chances of success. Here are some tips to help you ace your interview for a Railcar Carpenter position.

1. Research the Company and Position

Take the time to research the company and the specific position you are applying for. This will demonstrate your interest in the role and help you understand the company’s culture and values.

- Visit the company’s website to learn about their history, mission, and products or services.

- Read industry news and articles to stay up-to-date on the latest trends and developments.

2. Practice Your Answers

Prepare for common interview questions by practicing your answers in advance. This will help you feel more confident and articulate during the interview.

- Consider questions about your experience, skills, and qualifications.

- Practice answering situational questions that demonstrate your problem-solving and critical thinking abilities.

3. Dress Professionally

First impressions matter, so dress professionally for your interview. This shows that you are serious about the position and respect the company.

- Choose conservative colors such as black, navy, or gray.

- Wear clean and pressed clothing, including a suit or dress pants and a button-down shirt.

4. Be Punctual

Punctuality is essential for any job interview. Plan your route in advance and allow for extra time to account for traffic or unexpected delays.

- Aim to arrive at the interview location 10-15 minutes early.

- If you encounter any unexpected delays, call or email the interviewer to inform them.

5. Be Yourself

While it is important to put your best foot forward, it is also essential to be yourself during the interview. The interviewer wants to get to know the real you and assess whether you are a good fit for the company.

- Answer questions honestly and authentically.

- Showcase your personality and enthusiasm for the role.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Railcar Carpenter role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.