Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Prototype Carpenter interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Prototype Carpenter so you can tailor your answers to impress potential employers.

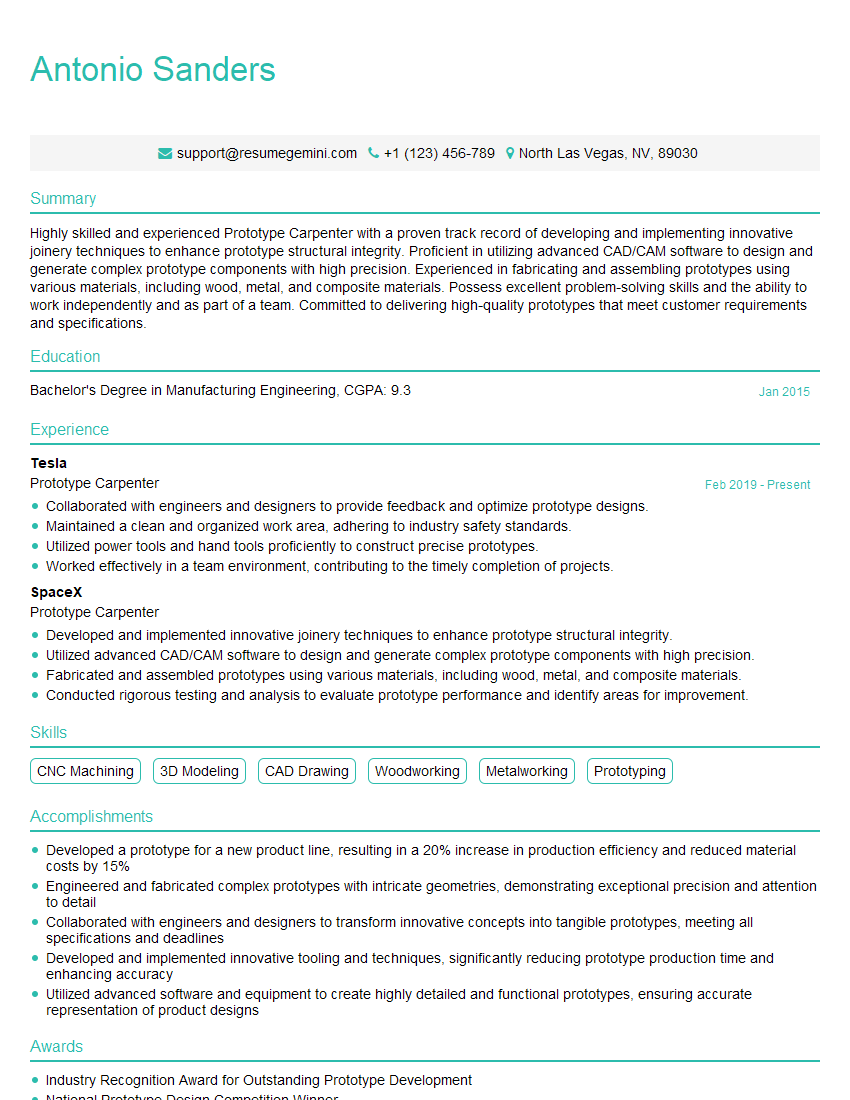

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Prototype Carpenter

1. How would you go about creating a prototype for a new furniture design?

As a Prototype Carpenter, I would follow these steps to create a prototype for a new furniture design:

- Gather information and specifications: I would begin by thoroughly reviewing the design specifications, including materials, dimensions, and functional requirements.

- Sketch and brainstorm: I would sketch out several concept designs to explore different ideas and refine the design. This step helps visualize the prototype and identify potential challenges.

- Select materials and tools: Based on the design and specifications, I would carefully select the appropriate materials and tools for constructing the prototype. Consider factors such as strength, durability, and cost.

- Build the prototype: Using the selected materials and tools, I would meticulously construct the prototype according to the design specifications. This involves cutting, shaping, assembling, and finishing the components.

- Test and evaluate: Upon completion, I would thoroughly test the prototype’s functionality, durability, and aesthetics. This may involve load testing, ergonomic assessment, and user feedback.

- Refine and iterate: Based on the test results, I would identify areas for improvement and make necessary modifications to enhance the design’s performance and user experience.

2. What types of materials are you experienced in using for prototyping?

Woods

- Hardwoods: Oak, Maple, Cherry, Walnut, Mahogany

- Softwoods: Pine, Fir, Spruce, Cedar, Redwood

Metals

- Steel

- Aluminum

- Stainless Steel

Plastics

- ABS

- PVC

- Polyethylene

Composites

- Fiber-reinforced plastics

- Wood-plastic composites

3. What are the different types of prototyping techniques you are familiar with?

- Manual Prototyping: Handcrafting prototypes using traditional tools and materials.

- 3D Printing: Creating prototypes using additive manufacturing technology that builds objects layer by layer.

- CNC Machining: Using computer-controlled machines to fabricate prototypes from various materials with high precision.

- Vacuum Forming: Forming plastic sheets into complex shapes using a mold and vacuum pressure.

- Rapid Tooling: Creating molds and tooling quickly to produce prototypes in small batches.

4. How do you ensure the accuracy and precision of your prototypes?

- Precise Measurements: I use calibrated measuring tools to ensure accurate dimensions and angles.

- Attention to Detail: I pay meticulous attention to every detail of the design, ensuring that the prototype closely matches the intended specifications.

- Quality Control: I implement quality control measures throughout the prototyping process to identify and correct any errors or inconsistencies.

- Testing and Validation: I conduct thorough testing to verify the prototype’s functionality and performance.

5. What are some of the challenges you have faced in prototyping and how did you overcome them?

- Complex Designs: I once encountered a design with intricate curves and tight tolerances. I overcame this by utilizing advanced CNC machining techniques and specialized tooling.

- Material Limitations: For a particular project, the required material was not readily available. I explored alternative materials and conducted extensive testing to find a suitable substitute.

- Time Constraints: On a time-sensitive project, I streamlined the prototyping process by optimizing workflow and working closely with the design team to prioritize tasks.

- Budget Constraints: I faced a project with limited budget. I explored cost-effective prototyping techniques and negotiated with suppliers to reduce material and production costs.

6. How do you stay up-to-date with the latest advancements in prototyping technologies?

- Industry Events and Conferences: I attend industry events and conferences to network with professionals and learn about emerging technologies.

- Online Resources: I subscribe to industry publications, online forums, and webinars to stay informed about the latest trends and advancements.

- Research and Development: I actively engage in research and development projects to explore new prototyping techniques and materials.

7. How do you collaborate with designers and engineers during the prototyping process?

- Regular Communication: I maintain open communication with designers and engineers throughout the prototyping process.

- Design Reviews: I participate in design reviews to provide feedback on feasibility and manufacturability.

- Prototyping Iterations: I work closely with the team to refine the design through multiple prototyping iterations.

- Technical Expertise: I share my technical expertise to guide the design team towards practical and cost-effective solutions.

8. How do you manage multiple prototyping projects simultaneously?

- Prioritization: I prioritize projects based on deadlines and importance.

- Time Management: I effectively manage my time using techniques such as task lists and scheduling.

- Delegation: When necessary, I delegate tasks to team members to ensure efficient progress.

- Communication: I communicate regularly with stakeholders to provide updates on project status and potential challenges.

9. How do you handle revisions and changes to the prototype design?

- Flexibility: I am flexible and adaptable to accommodate design revisions.

- Communication: I clarify the changes with the design team to ensure proper implementation.

- Time Management: I adjust my schedule to meet revised deadlines without compromising quality.

- Problem-Solving: I identify potential issues with revisions and work with the team to find solutions.

10. How do you ensure the quality of your prototypes meet the required standards?

- Attention to Detail: I pay meticulous attention to every aspect of the prototype, ensuring it meets the specified requirements.

- Quality Control: I implement quality control measures throughout the prototyping process to identify and correct any defects.

- Testing and Validation: I conduct thorough testing to verify the functionality, durability, and aesthetics of the prototype.

- Customer Feedback: I seek feedback from designers, engineers, and end-users to identify areas for improvement and ensure satisfaction.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Prototype Carpenter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Prototype Carpenter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a prototype Carpenter, you will play a vital role in turning design concepts into tangible prototypes. Your responsibilities will encompass a wide range of tasks, including:

1. Prototype Development

Interpreting design blueprints and specifications to build accurate prototypes.

- Utilizing various woodworking tools and equipment to create complex prototypes.

- Ensuring prototypes meet design specifications and functionality requirements.

2. Material Selection and Sourcing

Selecting and sourcing the appropriate materials for prototype construction.

- Considering factors such as strength, durability, and cost-effectiveness.

- Establishing relationships with suppliers to secure materials in a timely manner.

3. Quality Control

Conducting thorough inspections to ensure the quality and accuracy of prototypes.

- Verifying measurements, tolerances, and other critical specifications.

- Identifying and addressing any defects or deviations from design.

4. Communication and Collaboration

Communicating effectively with designers, engineers, and other stakeholders.

- Providing feedback on design and technical specifications.

- Participating in project discussions and brainstorming sessions.

Interview Tips

To ace your interview for a Prototype Carpenter position, it’s crucial to prepare thoroughly and showcase your skills and qualifications.

1. Research the Company and Industry

- Gain a deep understanding of the company’s mission, values, and products or services.

- Familiarize yourself with industry trends and key players.

2. Highlight Your Skills and Experience

- Quantify your accomplishments and demonstrate the impact of your work.

- Use specific examples to illustrate your proficiency in prototype development, material selection, and quality control.

3. Ask Thoughtful Questions

- Prepare insightful questions that show your interest and engagement.

- Inquire about the company’s growth plans, project pipelines, and opportunities for professional development.

4. Practice Your Pitch

- Craft a clear and concise introduction that summarises your skills and experience.

- Prepare responses to common interview questions, such as “Why are you interested in this role?”

5. Dress Professionally and Arrive on Time

- Make a positive first impression by dressing appropriately for the industry and occasion.

- Punctuality demonstrates respect for the interviewer’s time.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Prototype Carpenter, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Prototype Carpenter positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.