Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Hammerer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

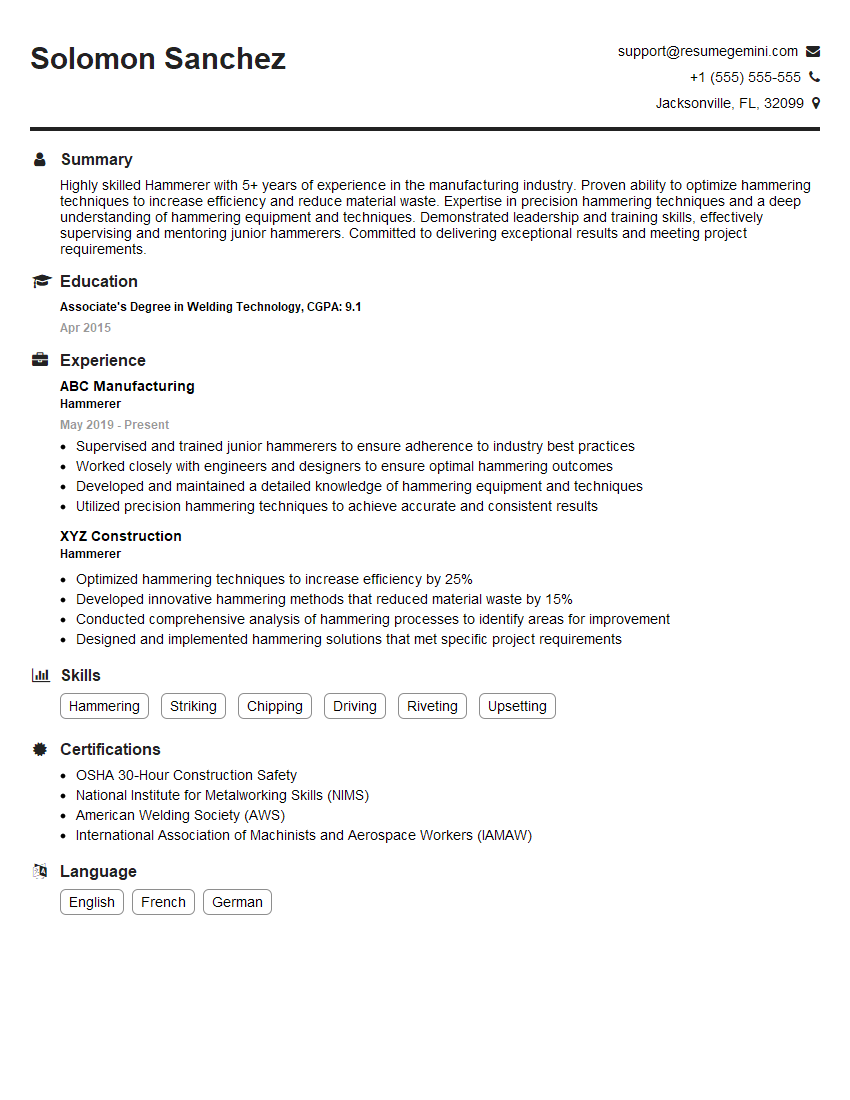

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hammerer

1. What are the types of hammers and their uses?

- Claw hammer: Used for driving nails and removing nails with its curved claw.

- Ball-peen hammer: Used for shaping and forming metal, such as in metalworking or jewelry-making.

- Sledgehammer: A heavy hammer used for breaking rocks, driving stakes, or demolishing structures.

- Mallet: Used for delicate tasks, such as assembling furniture or tapping in wooden dowels.

- Rubber mallet: A non-marring hammer used for tasks where damage to the surface is a concern, such as installing flooring or shaping materials.

2. What are the safety precautions that need to be taken while using a hammer?

- Wear eye protection, such as safety glasses or goggles, to prevent flying debris from entering the eyes.

- Wear gloves to protect hands from blisters and impact injuries.

- Ensure the hammer head is securely attached to the handle to prevent the head from flying off during use.

- Inspect the hammer regularly for damage, such as cracks or loose parts.

- Use the correct hammer for the task. For example, do not use a ball-peen hammer for driving nails.

3. What are the different techniques used for hammering?

- Overhead swing: Used for delivering maximum force, such as when driving large nails or breaking rocks.

- Side swing: Used for more controlled hammering, such as when assembling furniture or installing trim.

- Underhand swing: Used for tasks where precision is required, such as shaping metal or tapping in dowels.

- Two-handed grip: Used for added stability and power, especially when using heavier hammers.

4. What are the common mistakes made while using a hammer?

- Not wearing proper safety gear, such as eye protection or gloves.

- Using the wrong hammer for the task.

- Holding the hammer incorrectly, which can lead to blisters or impact injuries.

- Striking the hammer at an angle, which can damage the hammer or the workpiece.

- Over-hammering, which can damage the workpiece or cause the hammer to bounce back and hit the user.

5. What are the techniques for maintaining and sharpening a hammer?

- Keep the hammer head clean and free of rust or debris.

- Inspect the hammer regularly for damage and replace the handle if necessary.

- Sharpen the hammer head using a file or grindstone if it becomes dull.

- Store the hammer in a dry place when not in use.

6. What are the factors to consider when choosing the right hammer for a specific task?

- The weight of the hammer: Heavier hammers deliver more force but can be harder to control.

- The shape of the hammer head: Different head shapes are designed for different tasks, such as driving nails, shaping metal, or breaking rocks.

- The material of the hammer head: Steel hammers are durable but can damage delicate surfaces. Rubber hammers are non-marring but may not provide enough force for heavier tasks.

- The length of the handle: Longer handles provide more leverage but can be more difficult to control.

7. What are the techniques for using a hammer to remove nails?

- Use a nail puller or pry bar to lift the nail head slightly.

- Place the claw of the hammer under the nail head and pull backward.

- If the nail is deeply embedded, use a rocking motion to gradually work the nail out.

- Be careful not to break the workpiece or damage the surrounding material.

8. What are the common causes of hammer accidents and how can they be prevented?

- Not wearing proper safety gear.

- Using the wrong hammer for the task.

- Holding the hammer incorrectly.

- Striking the hammer at an angle.

- Over-hammering.

- Working in a cluttered or poorly lit area.

9. What are some of the advanced techniques for using a hammer, such as riveting or forging?

- Riveting: Using a hammer to set rivets, which are used to join two pieces of metal.

- Forging: Using a hammer to shape and form metal, such as in blacksmithing or jewelry-making.

- Planishing: Using a hammer to smooth and flatten metal surfaces.

- Dinking: Using a hammer and anvil to create small depressions or indentations in metal.

10. What are some of the innovative uses for a hammer beyond its traditional applications?

- As a percussion instrument in music.

- As a tool for breaking ice or concrete.

- As a weapon in self-defense.

- As a symbol of authority or power.

- As a decorative object or collectible.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hammerer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hammerer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Hammerers play a crucial role in forging metal components with precision and accuracy. Their primary responsibilities include:

1. Metal Preparation

Preparing metal blanks by cutting, shaping, and heating them to optimal temperatures

- Selecting appropriate tools and equipment for metal shaping

- Heating metal to the desired temperature using a forge or other heating equipment

2. Metal Shaping

Using hammers, presses, and other equipment to shape metal into desired forms

- Hammering metal to shape and reduce thickness

- Operating presses to bend, flatten, and form metal

- Performing hand-forging techniques to create intricate shapes

3. Metal Joining

Joining metal pieces using welding or other joining techniques

- Welding metal components together using various welding methods

- Fastening metal pieces using rivets, screws, or bolts

4. Quality Control

Inspecting and testing forged components to ensure specifications and quality standards are met

- Using measuring tools to verify dimensions and tolerances

- Performing visual inspections and non-destructive testing

Interview Tips

Preparing thoroughly for a Hammerer interview can significantly increase your chances of success. Here are some helpful tips:

1. Research the Company and Industry

Understand the company’s business, products, and manufacturing processes. Research the industry’s current trends, technologies, and market dynamics.

- Visit the company’s website and social media pages.

- Read industry publications and news articles.

- Network with professionals in the industry.

2. Practice Your Skills and Knowledge

Refresh your knowledge of metalworking techniques, equipment, and safety protocols. Practice using common tools used in hammering operations.

- Review technical manuals and textbooks.

- Set up a practice area to hone your skills.

- Seek feedback from experienced hammerers.

3. Prepare for Common Interview Questions

Anticipate questions about your experience, skills, and qualifications. Prepare thoughtful and concise answers that highlight your strengths and fit for the role.

- Why are you interested in this position?

- What are your strengths and weaknesses as a hammerer?

- Describe your experience with specific metalworking techniques.

4. Dress Professionally and Be Punctual

First impressions matter. Dress appropriately for the interview and arrive on time. Your appearance and punctuality demonstrate your professionalism and respect for the interviewer.

- Wear clean and pressed clothing suited for a manufacturing environment.

- Arrive at the interview venue a few minutes early.

- Be prepared to present a portfolio or samples of your work if requested.

5. Ask Intelligent Questions

Asking thoughtful questions conveys your interest and engagement in the opportunity. Prepare questions about the company, the position, and the industry.

- What are the company’s current projects and future plans?

- What is the typical career path for hammerers within the organization?

- How does the company ensure the safety and well-being of its employees?

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Hammerer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.