Are you gearing up for an interview for a Floor Sanding Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Floor Sanding Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

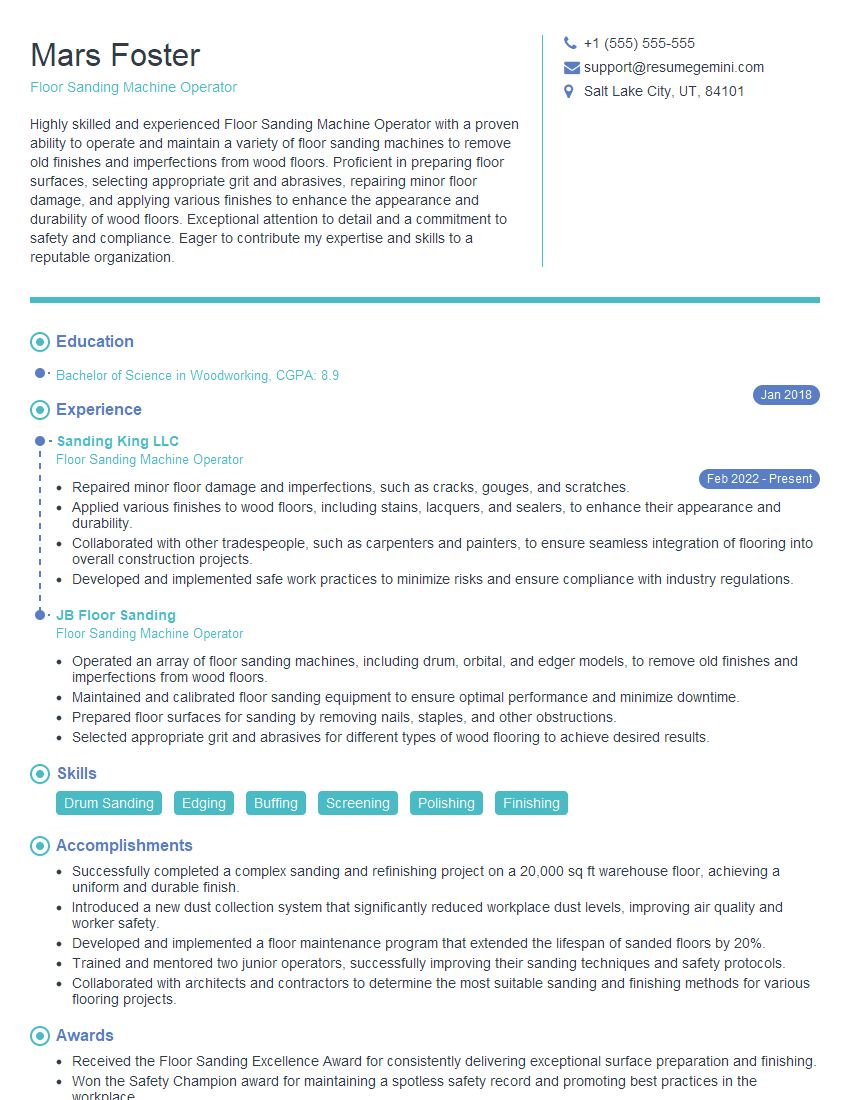

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Floor Sanding Machine Operator

1. What are the different types of floor sanding machines and their applications?

Floor sanding machines come in different types, each designed for specific applications. Here are the main types and their uses:

- Drum sanders: These machines have a cylindrical sanding drum that spins at high speed, removing the top layer of the floor. They are typically used for rough sanding and removing thick coatings or uneven surfaces.

- Edgers: Edgers are smaller machines designed to sand along edges and corners, where drum sanders cannot reach. They are commonly used for detailed sanding and finishing.

- Orbital sanders: Orbital sanders have a rotating sanding disc that moves in a circular motion. They are used to smooth surfaces and remove minor imperfections, leaving a finer finish than drum sanders.

- Belt sanders: Belt sanders use a continuous loop of sandpaper that runs over two rollers. They are powerful machines used for heavy-duty sanding tasks, such as removing old paint or glue.

2. How do you determine the correct grit size for sanding different types of floors?

Selecting Grit Size

- Hardwood floors: Start with a coarse grit (40-60) for rough sanding and gradually move to finer grits (80-120) for smoothing and finishing.

- Laminate floors: Use a medium grit (80-120) to avoid damaging the delicate surface.

- Concrete floors: Start with a very coarse grit (20-40) to remove deep scratches and imperfections, then progress to finer grits for smoothing.

- Stone floors: Choose a grit size appropriate for the type of stone. Softer stones like sandstone require finer grits (120-220), while harder stones like granite can handle coarser grits (80-120).

- Unfinished floors: Use a coarse grit (40-60) to remove imperfections and prepare the surface for staining or finishing.

3. What are the safety precautions that should be taken when operating a floor sanding machine?

To ensure safety during operation, follow these precautions:

- Wear proper safety gear, including a dust mask, hearing protection, and safety glasses.

- Inspect equipment before use, checking for any damaged cords, plugs, or belts.

- Ensure adequate ventilation in the work area to prevent dust build-up.

- Keep the machine away from flammable materials.

- Never leave the machine unattended while it is running.

- Follow the manufacturer’s instructions for proper operation and maintenance.

4. How do you troubleshoot common problems encountered with floor sanding machines?

When faced with machine issues, try these troubleshooting steps:

- Machine won’t start: Check the power source, switch, and fuses. Inspect for any loose connections.

- Sanding belt breaks frequently: Ensure proper belt tension and alignment. Check for worn or damaged belts and replace them if necessary.

- Uneven sanding: Adjust the machine’s settings, such as belt speed or drum pressure, to achieve a consistent finish.

- Excessive dust: Clean or replace the dust collection bag and ensure proper ventilation.

- Motor overheating: Turn off the machine immediately and allow it to cool down. Check for obstructions in the motor or ventilation system.

5. How do you ensure a high-quality finish when sanding floors?

To achieve a professional-looking finish:

- Prepare the floor properly by removing any nails, staples, or debris.

- Use the correct grit size for each stage of sanding.

- Sand in the direction of the wood grain.

- Overlap your strokes to avoid creating visible lines.

- Use a sanding screen or fine sandpaper to smooth the surface between grits.

- Vacuum or sweep thoroughly after sanding.

6. What is the purpose of using a floor buffer after sanding?

Floor buffering is essential for:

- Removing any remaining fine dust or debris: Buffering with a soft pad helps eliminate any dust left behind after sanding, ensuring a smooth surface for the finish.

- Burnishing the surface: Buffing with a harder pad or burnishing solution creates a slight sheen on the floor, enhancing its appearance and durability.

- Preparing the floor for finishing: Buffering helps to open the pores of the wood, making it more receptive to stains, sealers, or other finishes.

7. How do you determine the appropriate speed for sanding different types of floors?

Sanding Speed Guidelines

- Hardwood floors: Sand at a moderate speed to avoid gouging or damaging the wood.

- Laminate floors: Use a slower speed to prevent overheating and damaging the laminate surface.

- Concrete floors: Start at a slow speed and gradually increase it as needed to remove stubborn stains or imperfections.

- Stone floors: Sand at a low speed to prevent chipping or cracking the delicate stone surface.

8. What techniques do you use to prevent swirl marks when sanding floors?

To avoid swirl marks:

- Use overlapping strokes: Sanding in overlapping patterns helps minimize visible lines.

- Change the direction of sanding: Periodically change the direction of sanding to prevent the formation of parallel lines.

- Use a sanding screen or fine sandpaper: Smoothing the surface between grits with a sanding screen or fine sandpaper helps blend any remaining lines.

- Buff the floor: Buffing the floor after sanding with a soft pad helps remove any minor imperfections and enhance the overall finish.

9. How do you handle different types of wood floors, such as hardwood, laminate, and engineered wood?

Each floor type requires specific handling techniques:

- Hardwood floors: Sand with the grain and use the appropriate grit size to avoid damaging the delicate wood.

- Laminate floors: Use a fine grit and a slow sanding speed to prevent overheating and surface damage.

- Engineered wood floors: Sand carefully, following the grain and using a coarse grit to remove any imperfections.

10. Describe your experience in maintaining and repairing floor sanding machines.

Maintenance and Repair Experience

- Regularly clean and inspect machines to identify potential issues early.

- Replace worn or damaged parts promptly, such as sanding belts, brushes, and bearings.

- Lubricate moving parts according to the manufacturer’s instructions.

- Troubleshoot and resolve common problems, such as motor overheating or uneven sanding.

- Perform major repairs, such as replacing motors or transmissions, when necessary.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Floor Sanding Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Floor Sanding Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Floor Sanding Machine Operator, you will be responsible for a variety of tasks related to the operation and maintenance of floor sanding equipment. These key job responsibilities include:

1. Operating Floor Sanding Machines

Safely and efficiently operate floor sanding machines to remove old or damaged flooring surfaces.

- Adjust and calibrate sanding machines to achieve desired results.

- Select and use appropriate sandpaper grits to effectively remove different types of flooring materials.

2. Surface Preparation

Prepare flooring surfaces for sanding by removing furniture, fixtures, and other obstructions.

- Protect surrounding areas from dust and debris.

- Inspect surfaces for any damage or imperfections that may require special attention.

3. Sanding and Refinishing Floors

Sand floors to remove old finishes, level uneven surfaces, and create a smooth, uniform finish.

- Apply stains, sealers, or other finishes to enhance the appearance and durability of the floor.

- Inspect and touch up finished floors to ensure a high-quality result.

4. Equipment Maintenance

Maintain and troubleshoot floor sanding equipment to ensure optimal performance and safety.

- Clean and lubricate machines regularly.

- Identify and repair any mechanical or electrical issues.

Interview Tips

To ace your interview for a Floor Sanding Machine Operator position, consider the following tips:

1. Research the Company and Industry

Familiarize yourself with the company’s history, services, and industry trends. This will demonstrate your interest and enthusiasm for the role.

- Visit the company’s website and social media pages.

- Read industry publications and articles to gain insights into best practices.

2. Highlight Your Experience and Skills

Emphasize your relevant experience in operating floor sanding machines and preparing and finishing floors.

- Quantify your accomplishments whenever possible, using specific numbers and metrics.

- Be prepared to discuss your knowledge of different sanding techniques and equipment.

3. Demonstrate Safety Consciousness

Flooring sanding involves the use of heavy machinery and hazardous materials. Highlight your commitment to safety.

- Describe your experience in following safety protocols and wearing appropriate protective gear.

- Explain how you identify and mitigate potential hazards.

4. Be Enthusiastic and Professional

Show your enthusiasm for the role and the industry. Maintain a professional demeanor throughout the interview.

- Be prepared to answer questions about your interest in floor sanding and your career aspirations.

- Dress appropriately and arrive on time for the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Floor Sanding Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!