Feeling lost in a sea of interview questions? Landed that dream interview for Concrete Pointer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Concrete Pointer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

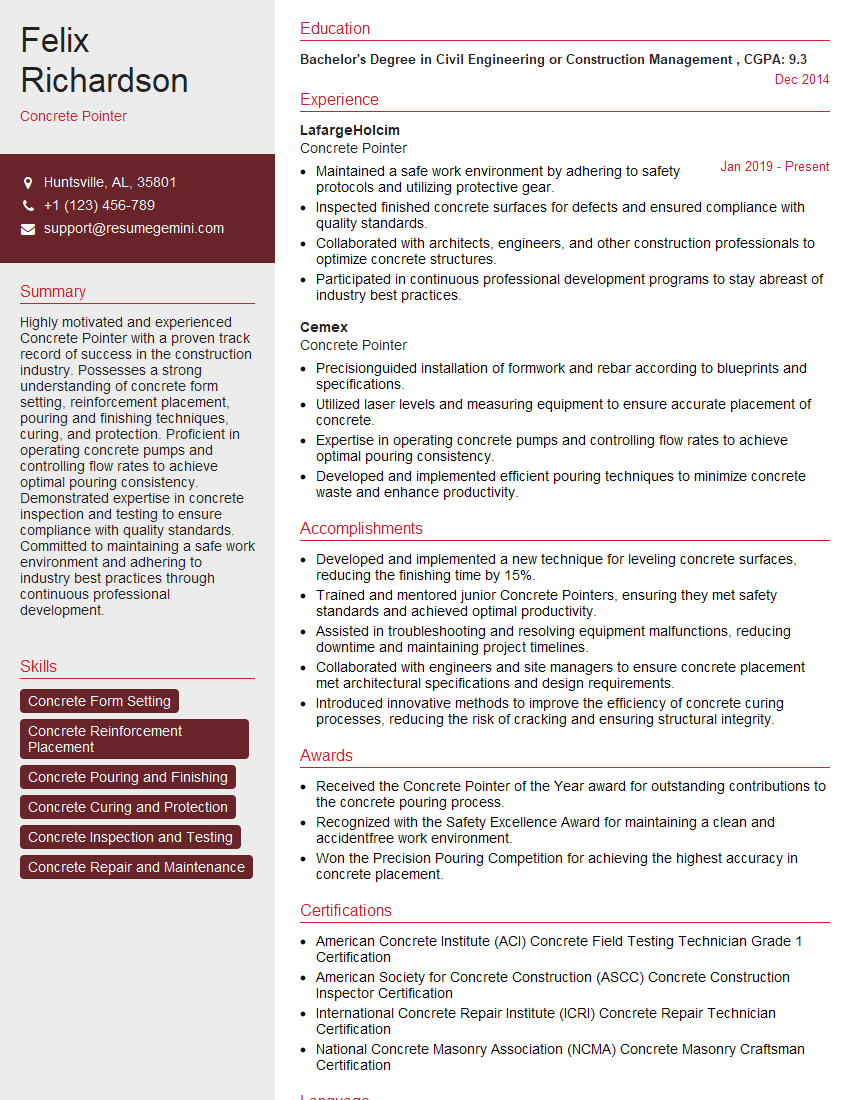

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Concrete Pointer

1. Describe the process of setting out and reading a dumpy level.

- Setting out a dumpy level involves placing the level on a stable and level surface and adjusting the leveling screws until the bubble is centered in the circular level.

- To read a dumpy level, the staff is held vertically and the line of sight is adjusted until it is level with the crosshairs in the telescope.

- The reading on the staff is then recorded, and the difference between the reading on the staff and the height of the instrument is used to calculate the elevation of the point being measured.

2. How do you ensure that a concrete pour is level and to the correct grade?

- To ensure that a concrete pour is level, the formwork must be set out and leveled prior to the concrete being poured.

- Once the concrete has been poured, it must be leveled using a screed or vibrating screed.

- The grade of the concrete can be checked using a laser level or by measuring the height of the concrete at regular intervals.

3. What are the different types of concrete finishes, and how are they achieved?

- There are a variety of different concrete finishes that can be achieved, depending on the desired aesthetic and functional requirements.

- Common concrete finishes include troweled finishes, broom finishes, exposed aggregate finishes, and stamped concrete finishes.

- Each type of finish is achieved using different techniques and materials, such as troweling, brushing, or stamping.

4. How do you test the strength of concrete?

- The strength of concrete is typically tested using compression tests.

- Compression tests are performed by applying a load to a concrete specimen until it fails.

- The strength of the concrete is then calculated based on the load that was applied and the dimensions of the specimen.

5. What are the most common problems that occur during concrete pours, and how can they be prevented?

- The most common problems that occur during concrete pours include cold joints, cracking, and honeycombing.

- Cold joints occur when fresh concrete is placed against hardened concrete, and they can be prevented by ensuring that the concrete is placed continuously and that the joints are properly finished.

- Cracking can be prevented by using proper curing techniques, such as covering the concrete with plastic or burlap and keeping it moist.

- Honeycombing occurs when there are voids in the concrete, and it can be prevented by using the proper concrete mix design and by placing and consolidating the concrete properly.

6. What are the different types of concrete admixtures, and what are their purposes?

- There are a variety of different concrete admixtures that can be used to improve the properties of concrete.

- Some of the most common types of concrete admixtures include water reducers, accelerators, retarders, and air-entraining agents.

- Water reducers are used to reduce the amount of water required for a concrete mix, which can improve the strength and durability of the concrete.

- Accelerators are used to speed up the setting and hardening of concrete, which can be useful in cold weather or when it is necessary to open the concrete to traffic quickly.

- Retarders are used to slow down the setting and hardening of concrete, which can be useful in hot weather or when it is necessary to place and finish the concrete over a longer period of time.

- Air-entraining agents are used to introduce small air bubbles into the concrete, which can improve the durability of the concrete by reducing the effects of freeze-thaw cycles.

7. What are the different types of concrete reinforcement, and how are they used?

- There are a variety of different types of concrete reinforcement that can be used to improve the strength and durability of concrete.

- Some of the most common types of concrete reinforcement include steel rebar, wire mesh, and fiber reinforcement.

- Steel rebar is the most common type of concrete reinforcement, and it is typically used in the form of bars or rods that are placed in the concrete.

- Wire mesh is a type of concrete reinforcement that is made from a grid of steel wires that are welded together.

- Fiber reinforcement is a type of concrete reinforcement that is made from small fibers that are added to the concrete mix.

8. What are the different types of concrete structures, and how are they designed?

- There are a variety of different types of concrete structures, including buildings, bridges, roads, and dams.

- Each type of concrete structure is designed to meet specific requirements, and the design process involves taking into account the loads that the structure will be subjected to, the materials that will be used, and the construction methods that will be employed.

9. What are the different types of concrete testing, and what are their purposes?

- There are a variety of different types of concrete testing that can be performed to assess the properties and performance of concrete.

- Some of the most common types of concrete testing include strength testing, durability testing, and non-destructive testing.

- Strength testing is used to determine the compressive strength of concrete, which is an important measure of its ability to resist loads.

- Durability testing is used to assess the resistance of concrete to various environmental conditions, such as freeze-thaw cycles and chemical attack.

- Non-destructive testing is used to test the properties of concrete without damaging the concrete, and it can be used to assess the strength, durability, and homogeneity of concrete.

10. What are the latest trends in concrete technology?

- The latest trends in concrete technology include the development of new types of concrete, such as self-consolidating concrete and ultra-high performance concrete.

- Self-consolidating concrete is a type of concrete that can be placed and compacted without the need for vibration, which can lead to improved strength and durability.

- Ultra-high performance concrete is a type of concrete that has a very high compressive strength and durability, which makes it suitable for use in a variety of applications, such as bridges and high-rise buildings.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Concrete Pointer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Concrete Pointer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Concrete Pointer is a skilled technician responsible for ensuring the quality and precision of concrete surfaces. They use specialized tools and techniques to smooth, level, and shape concrete to meet specific requirements.

1. Concrete Finishing

Pointers utilize various finishing tools, such as bull floats and power trowels, to achieve the desired texture and smoothness of concrete surfaces. They ensure that the concrete is properly consolidated to prevent voids and ensure structural integrity.

2. Leveling and Grading

Concrete pointers ensure that concrete surfaces are level and properly graded to facilitate drainage and prevent water accumulation. They use spirit levels, lasers, and other precision instruments to achieve accurate measurements.

3. Joint Creation

Pointers create contraction and expansion joints in concrete to control cracking and prevent structural damage. They use specialized saws and formwork to precisely cut and shape the joints.

4. Surface Repair and Maintenance

Concrete pointers are responsible for repairing and maintaining concrete surfaces. They patch cracks, fill voids, and apply sealants to protect concrete from deterioration and ensure its longevity.

Interview Tips

Preparing thoroughly for a Concrete Pointer interview is crucial to showcase your skills and demonstrate your suitability for the role.

1. Research the Company and Role

Thoroughly research the construction company and the specific role of a Concrete Pointer within that organization. Familiarize yourself with the company’s projects, industry reputation, and any specific requirements for the position.

2. Highlight Relevant Experience and Skills

Showcase your experience in concrete finishing, leveling, grading, joint creation, and surface repair. Emphasize your proficiency in using specialized tools and techniques and your attention to detail.

3. Prepare for Technical Questions

Expect technical questions related to concrete properties, finishing methods, and industry best practices. Be prepared to explain your understanding of concrete mix design, the importance of proper curing, and common challenges encountered in concrete work.

4. Demonstrate Safety Awareness

Emphasize your commitment to workplace safety and your knowledge of industry safety regulations. Highlight your experience using personal protective equipment and your understanding of safe work practices.

5. Practice Your Answers

Prepare thoughtful answers to common interview questions such as “Why are you interested in this role?” or “What are your strengths as a Concrete Pointer?” Practicing your responses will help you articulate your skills and qualifications confidently.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Concrete Pointer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.