Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Concrete Smoother position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

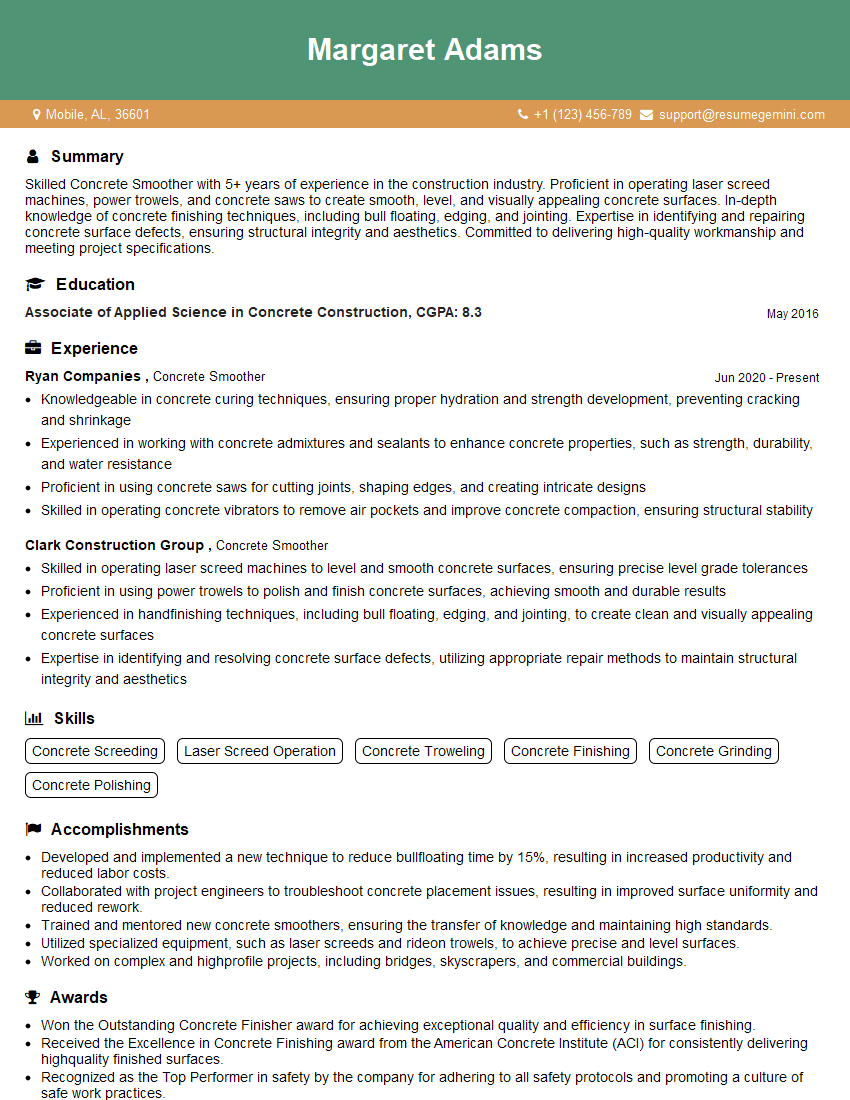

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Concrete Smoother

1. What are the different types of concrete smoothers and their applications?

There are several types of concrete smoothers, each with its unique applications:

- Bull floats: Used for large, flat surfaces. They have a long, flat blade that helps level and smooth the concrete.

- Darby: A handheld tool used for smaller areas or to smooth out uneven spots. It has a straight edge that is used to scrape and level the concrete.

- Power trowels: Mechanical tools that rotate a set of blades to smooth and finish the concrete surface. They are used for large, industrial projects.

- Hand trowels: Small, handheld tools used for finishing smaller areas or for detailed work. They come in various shapes and sizes.

2. Describe the proper techniques for using a bull float to smooth concrete.

Bull Float Technique:

- Hold the bull float parallel to the surface of the concrete.

- Move the bull float in a circular motion, overlapping each stroke.

- Apply even pressure to avoid creating ridges or voids.

- Keep the bull float flat on the surface to avoid creating ripples.

- Continue floating until the concrete is smooth and level.

3. Explain the importance of timing when smoothing concrete.

Timing is crucial when smoothing concrete, as it affects the finished texture and strength:

- Too early: If the concrete is smoothed too early, it may be too wet and difficult to work with, resulting in an uneven finish.

- Too late: If the concrete is smoothed too late, it may have started to set, making it difficult to achieve a smooth surface.

- Optimal timing: The ideal time to smooth concrete is when it is still workable but has begun to firm up slightly.

4. How do you handle uneven or rough spots in the concrete surface?

To handle uneven or rough spots:

- Use a darby to scrape away excess concrete and level the surface.

- Use a hand trowel to fill in any voids or depressions.

- Re-smooth the area using a bull float or power trowel to achieve a uniform finish.

5. Describe the safety precautions you follow when operating concrete smoothing equipment.

Safety precautions for concrete smoothing equipment include:

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a dust mask.

- Ensure that the equipment is in good working order and inspected regularly.

- Use ground fault circuit interrupter (GFCI) outlets to prevent electrical shocks.

- Never operate equipment alone.

- Be aware of your surroundings and maintain a safe distance from other workers and obstacles.

6. Explain how you maintain and clean concrete smoothing tools and equipment.

To maintain and clean concrete smoothing tools:

- Remove excess concrete from tools immediately after use.

- Wash tools thoroughly with water and a mild detergent.

- Dry tools completely to prevent rust.

- Sharpen blades or replace worn parts as needed.

- Lubricate moving parts to ensure smooth operation.

7. Describe the different types of concrete finishes and how to achieve them.

Types of concrete finishes and their techniques:

- Smooth finish: Achieved using a bull float or power trowel to create a flat, even surface.

- Broom finish: Created by dragging a broom across the surface of the concrete while it is still wet, resulting in a rough texture.

- Stamped finish: Obtained by pressing molds into the wet concrete to create patterns or designs.

- Exposed aggregate finish: Achieved by washing away the cement paste from the surface, exposing the aggregate stones.

8. How do you determine the correct moisture content of concrete for optimal smoothing?

To determine the correct moisture content:

- Use a moisture meter to measure the percentage of water in the concrete.

- Check the concrete’s appearance: it should be slightly damp but not wet enough to leave marks on your fingers.

- Perform a “ball-in-hand” test by forming a ball with the concrete: it should hold its shape but crumble slightly when squeezed.

9. Explain the importance of curing concrete after smoothing.

Curing concrete after smoothing is crucial for:

- Strength: Proper curing allows the concrete to gain strength and hardness.

- Durability: Curing prevents the concrete from cracking and deteriorating due to moisture loss.

- Finish: Curing helps maintain the desired finish and prevents surface defects.

10. Describe your experience with different types of concrete mixes and how they affect the smoothing process.

Different concrete mixes have varying properties that impact smoothing:

- Aggregate size: Larger aggregates require more effort to smooth, while smaller aggregates result in a smoother surface.

- Strength: High-strength concrete may require more power to smooth due to its density.

- Additives: Some additives, such as retarders or accelerators, can affect the timing and ease of smoothing.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Concrete Smoother.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Concrete Smoother‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Concrete Smoothers are responsible for ensuring that concrete surfaces are smooth and level, and free of defects such as voids, cracks, or unevenness. They use a variety of tools, including screeds, bull floats, and power trowels, to smooth and finish the concrete surface.Some of the key job responsibilities of a Concrete Smoother include:

1. Preparing the concrete surface

Before beginning the smoothing process, a Concrete Smoother must prepare the concrete surface by removing any debris or obstructions and ensuring that the surface is level.

- Cleaning the surface with a broom or water jet

- Removing any obstacles or debris from the surface

- Checking the surface for levelness

2. Applying the concrete

Once the surface is prepared, a Concrete Smoother will apply the concrete using a bucket or hopper. They will then spread the concrete evenly over the surface, using a screed to level it.

- Using a bucket or hopper to apply the concrete

- Spreading the concrete evenly over the surface

- Using a screed to level the concrete

3. Smoothing the concrete

Once the concrete has been applied, a Concrete Smoother will use a bull float to smooth the surface. A bull float is a large, flat tool that is dragged across the surface of the concrete to remove any bumps or ridges.

- Using a bull float to smooth the surface

- Dragging the bull float across the surface to remove bumps or ridges

- Repeating the process until the surface is smooth

4. Finishing the concrete

Once the concrete has been smoothed, a Concrete Smoother will use a power trowel to finish the surface. A power trowel is a machine that spins a blade at high speed, which helps to smooth and polish the concrete.

- Using a power trowel to finish the surface

- Spinning the blade of the power trowel at high speed

- Repeating the process until the surface is smooth and polished

Interview Tips

Preparing for a job interview can be daunting, but by following a few simple tips, you can increase your chances of success. Here are some tips to help you prepare for a Concrete Smoother interview:

1. Research the company and the position

Before you go to an interview, it is important to do your research on the company and the position you are applying for. This will help you to understand the company’s culture and values, and to tailor your answers to the specific requirements of the job.

- Visit the company’s website to learn about their history, products, and services.

- Read any news articles or press releases about the company.

- Check out the company’s social media pages to get a sense of their culture and values.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “Tell me about your experience.” It is important to practice your answers to these questions so that you can deliver them confidently and clearly.

- Write out your answers to common interview questions.

- Practice delivering your answers out loud to a friend or family member.

- Time yourself to make sure that your answers are concise and to the point.

3. Dress professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the job you are applying for.

- Wear a suit or dress pants and a button-down shirt.

- Make sure your clothes are clean and pressed.

- Avoid wearing revealing or casual clothing.

4. Be prepared to talk about your experience

The interviewer will want to know about your experience as a Concrete Smoother. Be prepared to talk about your skills and experience in detail.

- Highlight your experience in smoothing and finishing concrete surfaces.

- Describe the different tools and techniques you have used.

- Quantify your experience by providing specific examples of your work.

5. Be prepared to talk about your safety record

Working as a Concrete Smoother can be dangerous, so the interviewer will want to know about your safety record. Be prepared to talk about any safety training you have received and any steps you have taken to prevent accidents.

- Describe any safety training you have received.

- Explain how you follow safety procedures on the job.

- Discuss any steps you have taken to prevent accidents.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Concrete Smoother interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.