Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Joint Finisher position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

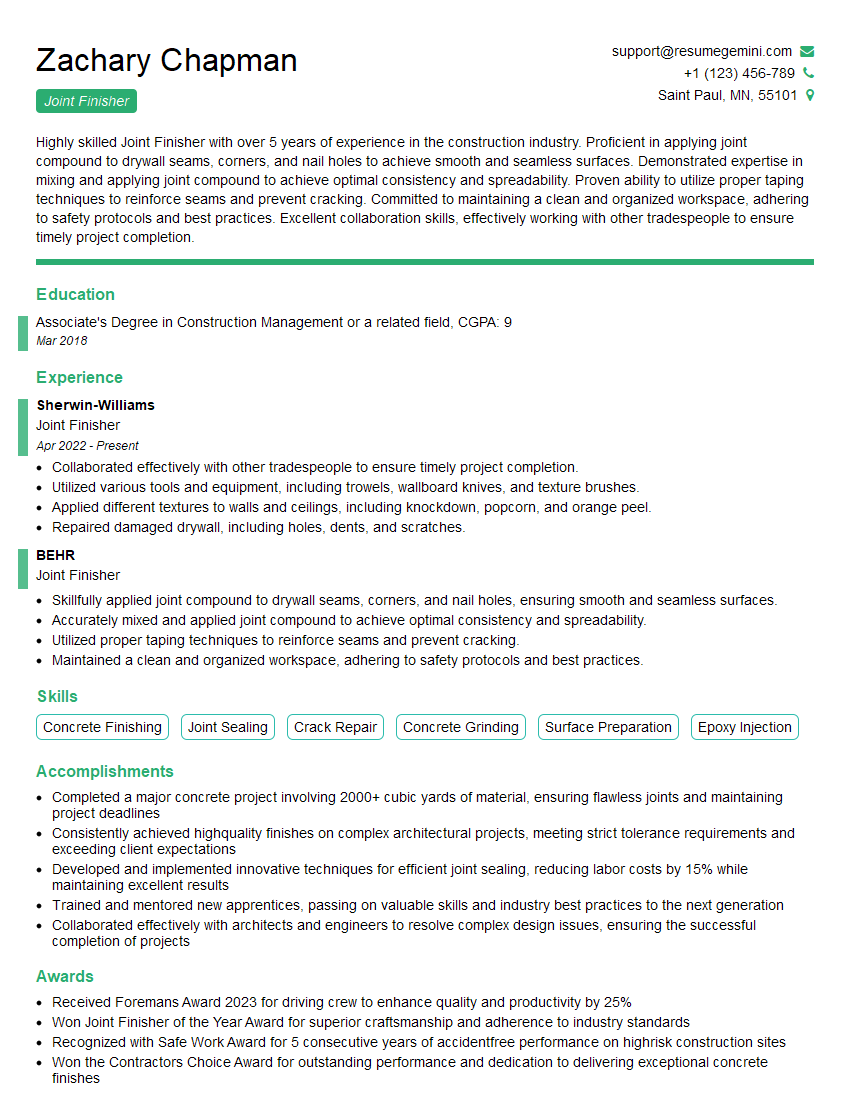

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Joint Finisher

1. What methods of joint finishing have you used in previous projects? Describe the process involved in each method and its benefits.

- Hand finishing: Using a trowel to smooth and level the joint by hand

- Edging tool: Using a specialized tool to create a clean and defined edge along the joint

- Mechanical finishing: Using a power tool, such as a buffer or sander, to smooth and level the joint efficiently

- Sponge floating: Using a damp sponge to smooth and consolidate the surface of the joint

2. What factors should be considered when selecting the appropriate joint finishing method?

Consistency of the joint compound

- Thin joint compound is suitable for hand finishing and edging

- Thicker joint compound may require mechanical finishing to achieve a smooth surface

Size and location of the joint

- Larger joints may require mechanical finishing for efficiency

- Joints in high-traffic areas may need a more durable finishing method, such as sponging

Desired level of smoothness

- Some projects may require a very smooth finish, which can be achieved through multiple passes with a mechanical finisher

- Other projects may only require a basic level of smoothness, which can be achieved through hand finishing

3. What techniques can be used to minimize the appearance of joints after finishing?

- Feathering the edges of the joint compound to blend it seamlessly with the surrounding surface

- Using a damp sponge to consolidate the joint compound and reduce shrinkage

- Applying a skim coat over the joint to create a uniform surface

- Sanding the joint lightly after it has dried to smooth any imperfections

4. How do you ensure that joints are properly sealed and protected from moisture?

- Applying a primer to the joint before finishing to prevent moisture penetration

- Using a waterproof joint compound or sealant to fill the joint

- Applying a topcoat or paint over the joint to create a protective barrier

5. What tools and equipment are essential for a joint finisher?

- Trowels of various sizes and shapes

- Edging tools

- Mechanical finisher

- Sponges

- Sandpaper

- Primer and sealant

6. What safety precautions should be taken when joint finishing?

- Wearing a respirator to prevent inhalation of dust

- Wearing gloves to protect hands from chemicals

- Using proper ventilation to ensure adequate airflow

- Following manufacturer’s instructions for the safe use of tools and materials

7. How do you troubleshoot common joint finishing problems, such as cracks, bubbles, and discoloration?

Cracks

- Check if the joint compound was applied too thinly or too quickly

- Feather the edges of the joint compound to blend it better with the surrounding surface

Bubbles

- Ensure that the joint compound was mixed properly and applied evenly

- Use a damp sponge to consolidate the joint compound and remove any trapped air

Discoloration

- Check if the joint compound was applied over a surface that was not properly primed

- Apply a skim coat over the joint to create a uniform surface and hide any discoloration

8. What is your experience with different types of joint systems, such as butt joints, miter joints, and corner joints?

- Butt joints: Finishing the joint by applying compound over the seam where two surfaces meet

- Miter joints: Finishing the joint where two surfaces meet at an angle, requiring precise cutting and fitting

- Corner joints: Finishing the joint where two surfaces meet at a 90-degree angle, using specialized techniques to create a strong and durable connection

9. How do you stay up-to-date with the latest techniques and materials used in joint finishing?

- Attend industry workshops and conferences

- Read trade publications and online resources

- Consult with manufacturers and suppliers for product updates and recommendations

10. Do you have any unique skills or experiences that would make you an exceptional joint finisher?

- Experience with specialized joint finishing techniques, such as Venetian plaster or epoxy resins

- Attention to detail and a commitment to delivering high-quality work

- Strong problem-solving skills and the ability to work independently

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Joint Finisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Joint Finisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

1. Finish Concrete Joints

Using hand tools or power tools, smooth and finish concrete joints to meet specifications.

- Inspect joints for imperfections and make necessary repairs.

- Utilize trowels, edgers, and other tools to achieve desired texture and shape.

2. Prepare Concrete Surfaces

Prepare concrete surfaces by cleaning, floating, and leveling to ensure proper adhesion.

- Remove debris, grease, and laitance from surfaces.

- Use bull floats, darbies, and other equipment to level and smooth surfaces.

3. Grout and Seal Joints

Fill joints with grout or sealant to seal and protect against water penetration.

- Apply grout or sealant into joints using trowels or caulking guns.

- Finish joints to a smooth and aesthetically pleasing appearance.

4. Repair Concrete Defects

Identify and repair concrete defects such as cracks, spalling, or delamination.

- Determine the cause of defects and implement appropriate repair methods.

- Use patching materials, epoxy, or other materials to restore the integrity of concrete.

Interview Tips

An interview is a job candidate’s opportunity to make a positive impression on the potential employer. The following tips will help candidates ace their job interview for a Joint Finisher position:

1. Research the Company and Position

Before the interview, it is imperative to thoroughly research the company and the specific Joint Finisher position. This will demonstrate a genuine interest in the opportunity and show that the candidate has taken the time to learn about the organization.

- Visit the company website to gather information about their history, values, and current projects.

- Review the job description carefully to understand the specific responsibilities, qualifications, and expectations of the role.

2. Practice Common Interview Questions

Prepare for common interview questions by practicing your answers. This will help build confidence and reduce nervousness during the actual interview.

- Anticipate questions about your experience, skills, and qualifications.

- Consider how you can highlight your accomplishments and demonstrate your suitability for the role.

3. Bring a Portfolio or Samples of Your Work

If possible, bring a portfolio or samples of your previous work to the interview. This can provide tangible evidence of your skills and abilities as a Joint Finisher.

- Include examples of your best work, showcasing your attention to detail and craftsmanship.

- Be prepared to discuss your projects and explain the techniques and materials you used.

4. Highlight Relevant Skills and Experience

During the interview, emphasize your relevant skills and experience that align with the requirements of the Joint Finisher position.

- Discuss your proficiency in using hand and power tools for concrete finishing.

- Highlight your experience in preparing, grouting, and sealing concrete joints.

- Share examples of your ability to repair concrete defects and ensure the integrity of concrete structures.

5. Show Enthusiasm and Professionalism

Throughout the interview, maintain a positive attitude and demonstrate your enthusiasm for the Joint Finisher role. Be respectful, professional, and ask thoughtful questions to show your engagement.

- Dress appropriately and arrive on time for the interview.

- Be polite and courteous to the interviewer and other staff you may encounter.

- Follow up with a thank-you note after the interview, expressing your appreciation and reiterating your interest in the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Joint Finisher interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!