Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Joint Setter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

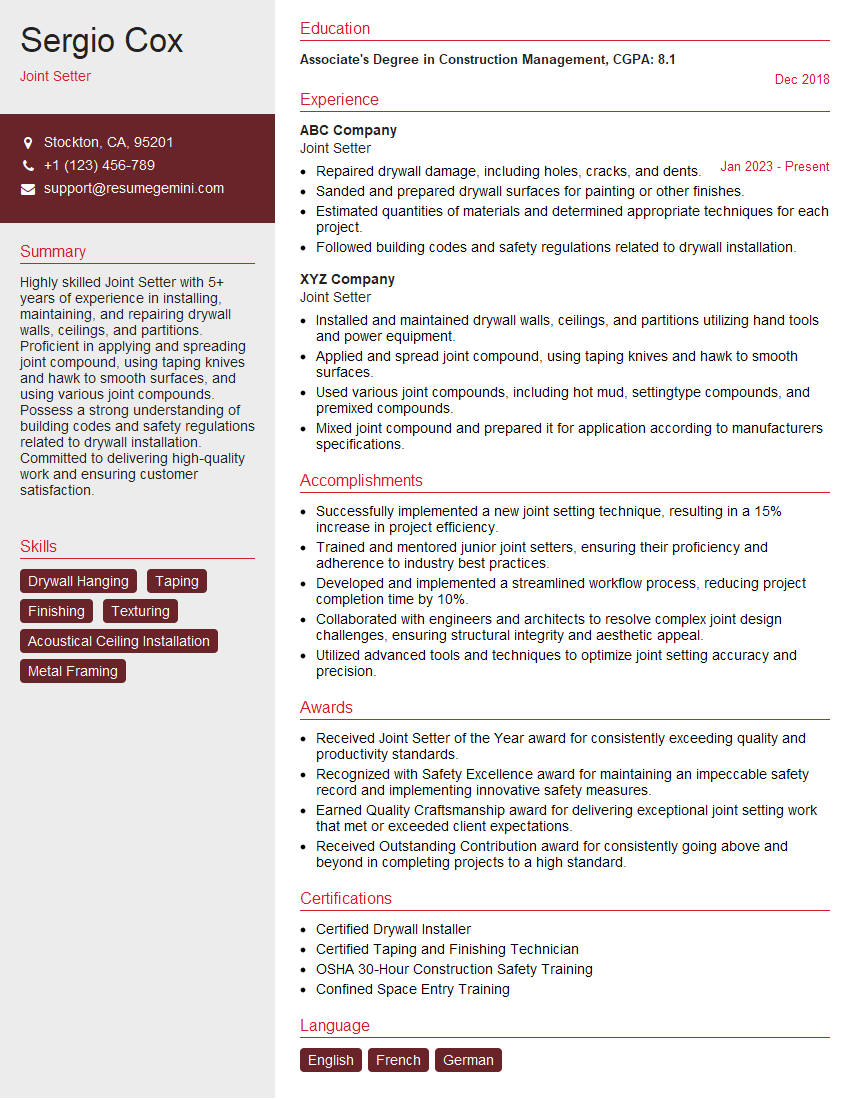

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Joint Setter

1. How do you ensure that the joints you set are square and level?

To ensure that the joints I set are square and level, I follow these steps:

- I use a framing square to make sure that the corners of the joint are at 90 degrees.

- I use a level to make sure that the joint is level both horizontally and vertically.

- I check the joint for square and level multiple times throughout the setting process to ensure accuracy.

2. What are the different types of joints that you can set, and what are their strengths and weaknesses?

Types of Joints

- Butt Joint: This is the simplest joint, where two pieces of wood are joined end-to-end. It is weak in tension and shear, but strong in compression.

- Lap Joint: This joint is formed by overlapping two pieces of wood. It is stronger than a butt joint in tension and shear, but weaker in compression.

- Dado Joint: This joint is formed by cutting a groove into one piece of wood and then fitting a tenon from the other piece of wood into the groove. It is strong in all directions.

Strengths and Weaknesses

- Butt Joint: Strong in compression, weak in tension and shear.

- Lap Joint: Stronger than butt joint in tension and shear, weaker in compression.

- Dado Joint: Strong in all directions.

3. What are the different tools and materials that you use in your work?

The following are the tools and materials that I use in my work:

- Tools: Framing square, level, hammer, nail gun, saw, chisel, sandpaper.

- Materials: Wood, nails, screws, glue.

4. What are the safety precautions that you take when setting joints?

I take the following safety precautions when setting joints:

- I wear safety glasses.

- I use sharp tools.

- I keep my work area clean and free of debris.

- I follow all manufacturer’s instructions for the tools and materials that I use.

5. What are the quality standards that you follow when setting joints?

I follow the following quality standards when setting joints:

- The joints must be square and level.

- The joints must be strong and durable.

- The joints must be aesthetically pleasing.

6. What are the different types of adhesives that you use in your work?

Types of Adhesives

- Wood glue: This is the most common type of adhesive used in woodworking. It is strong, durable, and easy to use.

- Epoxy: This adhesive is very strong and durable. It is often used for bonding metal, plastic, and wood.

- Cyanoacrylate: This adhesive is also known as super glue. It is very strong and fast-acting. It is often used for bonding small pieces of wood or other materials.

7. What are the advantages and disadvantages of using adhesives in joint setting?

Advantages

- Adhesives can help to create stronger joints.

- Adhesives can help to fill gaps between joints.

- Adhesives can help to prevent joints from coming apart.

Disadvantages

- Adhesives can take time to dry.

- Adhesives can be messy to use.

- Adhesives can be expensive.

8. How do you troubleshoot common joint setting problems?

I troubleshoot common joint setting problems by following these steps:

- I identify the problem.

- I determine the cause of the problem.

- I find a solution to the problem.

- I implement the solution.

9. What are the different types of joint reinforcement that you use?

Types of Joint Reinforcement

- Gussets: These are triangular pieces of metal or wood that are used to reinforce joints.

- Dowels: These are round rods that are inserted into holes drilled into the joint.

- Screws: These are threaded fasteners that are used to hold joints together.

10. What are the advantages and disadvantages of using joint reinforcement?

Advantages

- Joint reinforcement can help to create stronger joints.

- Joint reinforcement can help to prevent joints from coming apart.

- Joint reinforcement can help to extend the life of joints.

Disadvantages

- Joint reinforcement can be expensive.

- Joint reinforcement can be time-consuming to install.

- Joint reinforcement can be unsightly.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Joint Setter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Joint Setter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Joint Setters play a crucial role in the drywall installation process. They are responsible for the efficient and accurate placement and fastening of drywall panels onto walls and ceilings.

1. Drywall Installation

Properly position, secure, and fasten drywall panels to walls and ceilings using appropriate tools and techniques.

- Measure, cut, and fit drywall panels to exact specifications.

- Apply drywall compound to joints and seams to create a smooth and seamless surface.

2. Joint Treatment

Fill and smooth joints between drywall panels to create a uniform and aesthetically pleasing surface.

- Apply drywall compound to joints using taping knives or trowels.

- Sand and finish treated joints to achieve a smooth and even surface.

3. Surface Preparation

Effectively prepare drywall surfaces for painting or other finishing treatments.

- Sand drywall surfaces to remove imperfections and create a smooth base.

- Apply primer or sealant to ensure proper adhesion of paint or other finishes.

4. Attention to Detail

Ensure accuracy and precision in all aspects of drywall installation and finishing.

- Pay meticulous attention to measurements, cuts, and joint treatments.

- Inspect completed work thoroughly to identify and correct any defects.

Interview Preparation Tips

Preparing thoroughly for an interview is essential to showcase your skills and increase your chances of success.

1. Research the Company and Position

Take the time to learn about the company’s history, values, and current projects. Familiarize yourself with the specific requirements of the Joint Setter role.

- Visit the company’s website and social media pages.

- Review industry publications and articles to gain insights into the company’s operations.

2. Highlight Your Skills and Experience

Identify your most relevant skills and experiences that align with the job responsibilities. Quantify your accomplishments whenever possible.

- Emphasize your proficiency in drywall installation, joint treatment, and surface preparation techniques.

- Provide examples of projects where you successfully installed and finished drywall to a high standard.

3. Practice Common Interview Questions

Prepare answers to common interview questions related to your skills, experience, and motivation. Practice your responses to ensure they are clear and articulate.

- Tell me about your experience in drywall installation.

- Describe your approach to ensuring the accuracy and quality of your work.

4. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview demonstrates your engagement and interest in the position.

- Can you provide more details about the company’s current drywall projects?

- What are the opportunities for professional development within the company?

5. Dress Professionally and Arrive on Time

Dress appropriately for the interview and arrive on time to show respect for the interviewer and the company.

- Wear clean, presentable clothing suitable for a construction environment.

- Plan your route and allow extra time for unexpected delays.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Joint Setter, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Joint Setter positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.