Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Asphalt Tamper position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

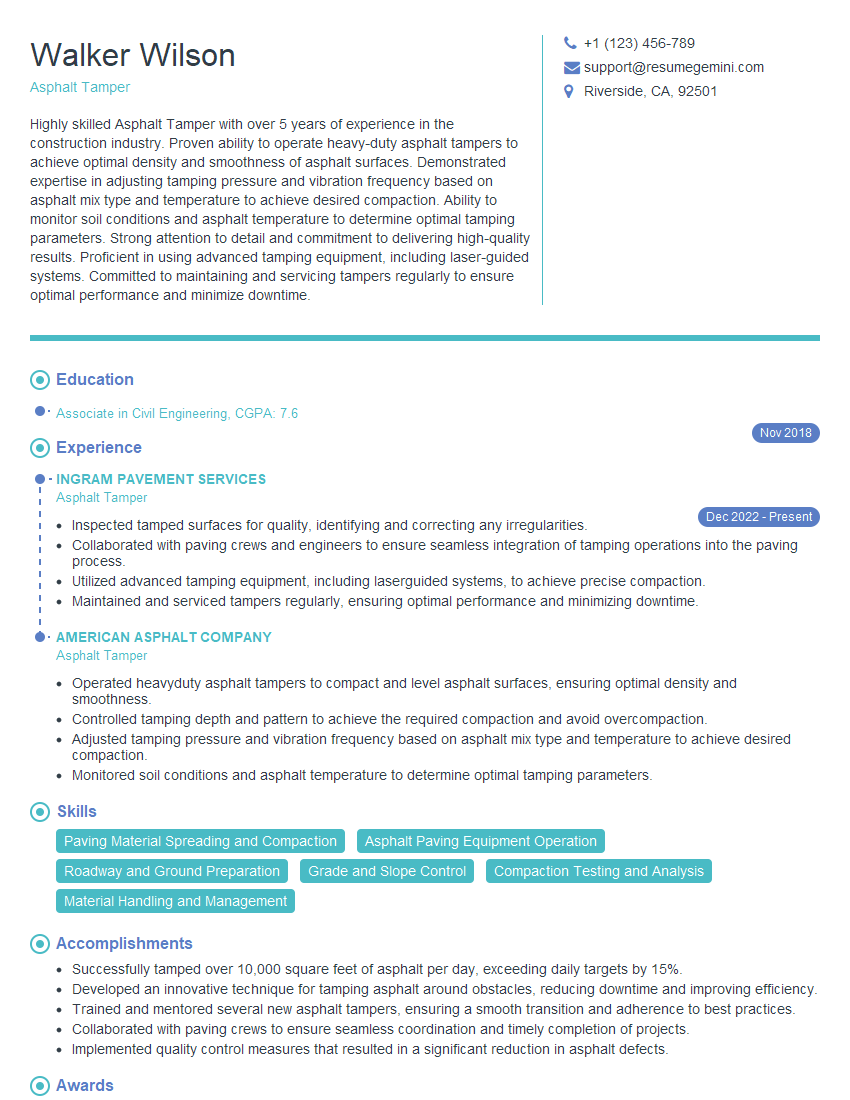

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Asphalt Tamper

1. Describe the typical daily responsibilities of an Asphalt Tamper.

- Operate and maintain asphalt tamps to compact and smooth asphalt surfaces.

- Inspect asphalt surfaces for defects.

- Adjust tamper settings to achieve desired compaction.

- Monitor the operation of the machine to ensure it is running smoothly and efficiently.

- Perform preventive maintenance on the machine, such as greasing and oil changes.

- Troubleshoot and repair any mechanical problems that may occur.

- Report any accidents or incidents to the supervisor.

- Follow all safety regulations and protocols.

2. What are the key skills required to be a successful Asphalt Tamper?

- Physical Ability: Must be able to stand for long periods of time and perform physical labor.

- Attention to Detail: Must be able to identify and correct surface defects.

- Mechanical Aptitude: Must be able to operate and maintain the asphalt tamper.

- Problem-Solving Skills: Must be able to troubleshoot and repair mechanical problems.

- Communication Skills: Must be able to communicate effectively with supervisors and other workers.

3. Explain the importance of proper compaction in asphalt paving.

Proper compaction ensures the asphalt surface is:

- Strong and durable

- Resistant to cracking and rutting

- Able to withstand heavy traffic loads

- Smooth and safe for vehicles and pedestrians

- Compaction also helps to reduce the amount of air voids in the asphalt, which can lead to premature deterioration.

4. What are the different types of asphalt tampers?

Vibratory Tampers

- Use vibrations to compact asphalt

- Most common type of tamper

- Produce a smooth, dense surface

Static Tampers

- Use heavy weights to compact asphalt

- Produce a very dense surface

- Less common than vibratory tampers

Pneumatic Tampers

- Use compressed air to compact asphalt

- Produce a smooth, even surface

- Good for compacting asphalt in tight spaces

5. How do you determine the correct compaction settings for an asphalt tamper?

- The correct compaction settings will depend on the type of asphalt being used, the thickness of the layer being compacted, and the desired level of compaction.

- It is important to follow the manufacturer’s instructions for the specific tamper being used.

- As a general rule, the higher the frequency of vibration, the greater the compaction.

- The amplitude of vibration should also be adjusted to achieve the desired level of compaction.

6. How do you troubleshoot a problem with an asphalt tamper?

- First, identify the problem.

- Once the problem has been identified, consult the manufacturer’s instructions or a qualified mechanic.

- Follow the troubleshooting steps carefully.

- If the problem cannot be resolved, contact the manufacturer for assistance.

7. What are the safety precautions that must be taken when operating an asphalt tamper?

- Always wear appropriate safety gear, including a hard hat, safety glasses, and gloves.

- Be aware of your surroundings and other workers in the area.

- Do not operate the tamper in wet or icy conditions.

- Keep the tamper in good working condition and perform regular maintenance.

- Follow all manufacturer’s instructions and safety guidelines.

8. How do you maintain an asphalt tamper?

- Regularly clean the tamper and remove any asphalt buildup.

- Lubricate all moving parts according to the manufacturer’s instructions.

- Check the hydraulic system for leaks and make sure the fluid level is correct.

- Inspect the tamper’s frame and welds for any damage.

- Perform any necessary repairs or adjustments.

- Keep a maintenance log to track all maintenance activities.

9. What are the different types of asphalt mixtures?

- Hot Mix Asphalt (HMA): Made with asphalt binder and heated aggregates

- Warm Mix Asphalt (WMA): Made with asphalt binder and heated aggregates at a lower temperature than HMA

- Cold Mix Asphalt (CMA): Made with asphalt binder and unheated aggregates

- Open Graded Asphalt (OGA): Has a high percentage of air voids

- Dense Graded Asphalt (DGA): Has a low percentage of air voids

10. Describe the process of paving an asphalt road.

- Preparation: The roadbed is prepared by grading and compacting it.

- Asphalt Placement: The asphalt is placed on the roadbed using a paving machine.

- Compaction: The asphalt is compacted using a roller.

- Cooling: The asphalt is allowed to cool and cure.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Asphalt Tamper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Asphalt Tamper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As an Asphalt Tamper, you will play a vital role in ensuring the quality and durability of asphalt surfaces. Your primary responsibilities will involve:

1. Preparing Asphalt Surfaces

Before applying asphalt, you will be responsible for preparing the surface to ensure proper adhesion. This may involve:

- Removing debris and foreign objects

- Leveling the surface using grading equipment

- Applying a base coat or primer to improve adhesion

2. Handling and Operating Asphalt Tampers

You will be skilled in operating various types of asphalt tampers, such as:

- Hand-held tampers for small areas

- Ride-on tampers for larger projects

- Self-propelled tampers for increased efficiency

3. Compacting Hot Asphalt Surfaces

Your primary task will be to compact hot asphalt surfaces to achieve the desired density and smoothness.

- Controlling the compaction pressure and temperature

- Ensuring uniform coverage and proper thickness

- Monitoring the curing process to prevent cracking

4. Ensuring Surface Quality and Compliance

You will be responsible for maintaining the quality of the finished asphalt surface, including:

- Checking for smoothness and absence of voids

- Enforcing specifications and standards

- Working closely with supervisors and inspectors

Interview Tips

To ace your interview for an Asphalt Tamper position, consider the following tips:

1. Research the Company and Industry

Demonstrate your interest and knowledge by researching the company and the asphalt industry. Understand their projects, values, and any recent advancements.

2. Highlight Your Experience and Skills

Emphasize your previous experience in asphalt paving and your proficiency in operating different types of tampers. Showcase your ability to work in challenging conditions and meet deadlines.

3. Be Prepared for Technical Questions

Anticipate questions related to asphalt compaction techniques, equipment safety, and quality control procedures. Study the industry standards and best practices to demonstrate your technical knowledge.

4. Display Teamwork and Physical Fitness

Asphalt Tamper roles require teamwork and physical stamina. Highlight your ability to work effectively with others and your willingness to perform physically demanding tasks.

5. Ask Thoughtful Questions

Prepare insightful questions about the company, the project, or the asphalt industry. This shows your engagement and eagerness to learn more.

Example Outline for Interview Answer

Question: Tell me about your experience with operating asphalt tampers. Answer: * Start by stating your years of experience and the types of tampers you have operated. * Highlight your proficiency in controlling compaction pressure, temperature, and coverage. * Provide examples of projects where you achieved exceptional surface quality and met specifications. * Conclude by emphasizing your commitment to safety and efficiency.Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Asphalt Tamper interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!