Are you gearing up for an interview for a Material Requirements Worker position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Material Requirements Worker and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

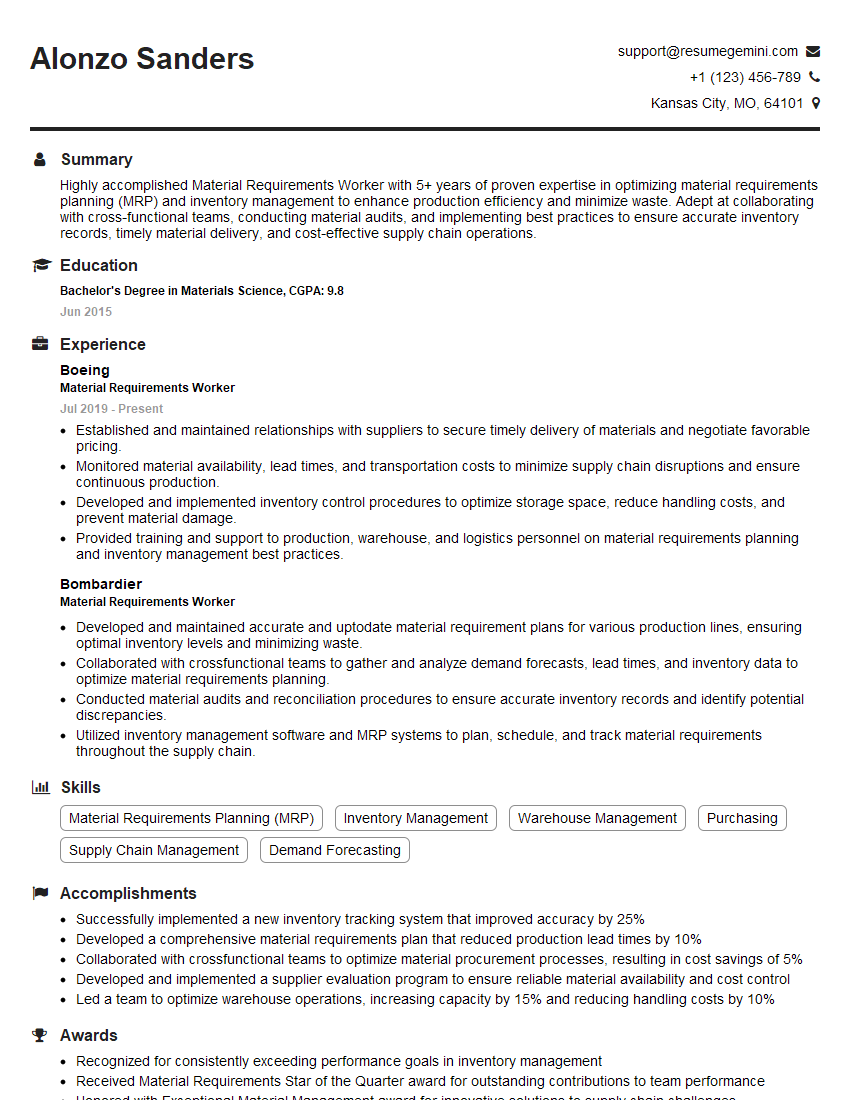

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Material Requirements Worker

1. What is the role of a Material Requirements Worker?

As a Material Requirements Worker, my key responsibility would be to efficiently manage and forecast material requirements for production processes. I would work closely with various departments to ensure the seamless flow of materials, optimize inventory levels, and minimize production disruptions.

2. How do you determine material requirements?

Material Planning

- Analyze production schedules and historic demand data.

- Identify material requirements for each production stage and component.

- Consider lead times, safety stock, and potential production changes.

Supplier Management

- Establish relationships with suppliers and track material availability.

- Negotiate prices and delivery schedules to secure timely material supply.

3. What inventory management techniques are you familiar with?

I am well-versed in various inventory management techniques, including:

- Just-in-time (JIT) inventory: Minimizing inventory levels to reduce waste and storage costs.

- Safety Stock Management: Maintaining a buffer stock to mitigate supply chain disruptions.

- ABC Analysis: Prioritizing inventory items based on their impact on production and costs.

4. How do you prioritize material requirements in case of shortages?

In the event of material shortages, I would prioritize material requirements based on:

- Criticality of the material for production.

- Urgency and impact of the production order.

- Availability of alternative materials or suppliers.

5. What software applications are you proficient in for material requirements planning?

I am proficient in the following software applications:

- Material Requirements Planning (MRP) systems.

- Enterprise Resource Planning (ERP) systems with MRP modules.

- Spreadsheets and databases for data analysis and reporting.

6. How do you communicate material requirements to relevant stakeholders?

I ensure effective communication of material requirements through:

- Regular reports and updates to production, procurement, and engineering teams.

- Participation in project meetings and cross-functional discussions.

- Use of communication tools such as email, instant messaging, and collaboration platforms.

7. What are some common challenges you expect to face in this role?

Some common challenges I anticipate in this role include:

- Managing fluctuating material availability and price changes.

- Coordinating with multiple departments and suppliers to ensure timely material delivery.

- Optimizing inventory levels to balance production needs and minimize waste.

8. How do you stay updated on industry best practices and trends in material requirements planning?

To stay updated on industry best practices and trends, I:

- Attend industry conferences and workshops.

- Read trade publications and research articles.

- Network with other professionals in the field.

9. What is your approach to continuous improvement in material requirements planning?

My approach to continuous improvement includes:

- Regularly reviewing and analyzing material consumption data to identify areas for optimization.

- Seeking feedback from stakeholders to understand their needs and pain points.

- Implementing new technologies and processes to improve efficiency and accuracy.

10. What sets you apart from other candidates for this role?

My combination of technical skills, industry knowledge, and commitment to continuous improvement sets me apart from other candidates. I am confident that I can effectively manage material requirements, optimize inventory, and contribute to the success of your organization.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Material Requirements Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Material Requirements Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Material Requirements Worker is responsible for planning and managing the material needs of a manufacturing or production facility. Key job responsibilities include:

1. Planning and forecasting material requirements

This involves analyzing production schedules, inventory levels, and lead times to determine the quantity and type of materials needed to meet production goals. The worker must also consider factors such as safety stock levels, supplier lead times, and potential production disruptions.

2. Sourcing and procuring materials

The worker is responsible for finding and selecting suppliers for materials, negotiating prices, and placing orders. They must also ensure that materials meet quality standards and are delivered on time.

3. Managing inventory

The worker is responsible for maintaining inventory levels of materials, including tracking inventory levels, managing storage space, and ensuring that materials are properly stored and handled.

4. Monitoring and controlling costs

The worker is responsible for monitoring and controlling costs associated with material procurement and inventory management. This includes tracking material costs, negotiating discounts with suppliers, and implementing cost-saving measures.

Interview Tips

To help you ace your interview for a Material Requirements Worker position, here are some tips and preparation strategies:

1. Research the company and position

Before the interview, take the time to learn about the company’s business, products, and services. Also, research the specific Material Requirements Worker position and its responsibilities.

2. Practice answering common interview questions

Some common interview questions for Material Requirements Workers include:

- Tell me about your experience in planning and forecasting material requirements.

- How do you identify and select suppliers?

- What are your strategies for managing inventory levels?

- How do you monitor and control costs associated with material procurement and inventory management?

3. Highlight your skills and experience

In your interview, be sure to highlight your skills and experience that are relevant to the job. These may include:

- Strong analytical skills

- Excellent communication and interpersonal skills

- Ability to work independently and as part of a team

- Experience with material planning and management software

4. Prepare questions for the interviewer

At the end of the interview, you may have the opportunity to ask the interviewer questions. This is a good chance to show your interest in the position and the company. Some good questions to ask include:

- What are the biggest challenges facing the company in terms of material requirements planning and management?

- What are the company’s goals for improving material requirements planning and management?

- What are the opportunities for professional development and advancement within the company?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Material Requirements Worker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.