Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Riveter interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Riveter so you can tailor your answers to impress potential employers.

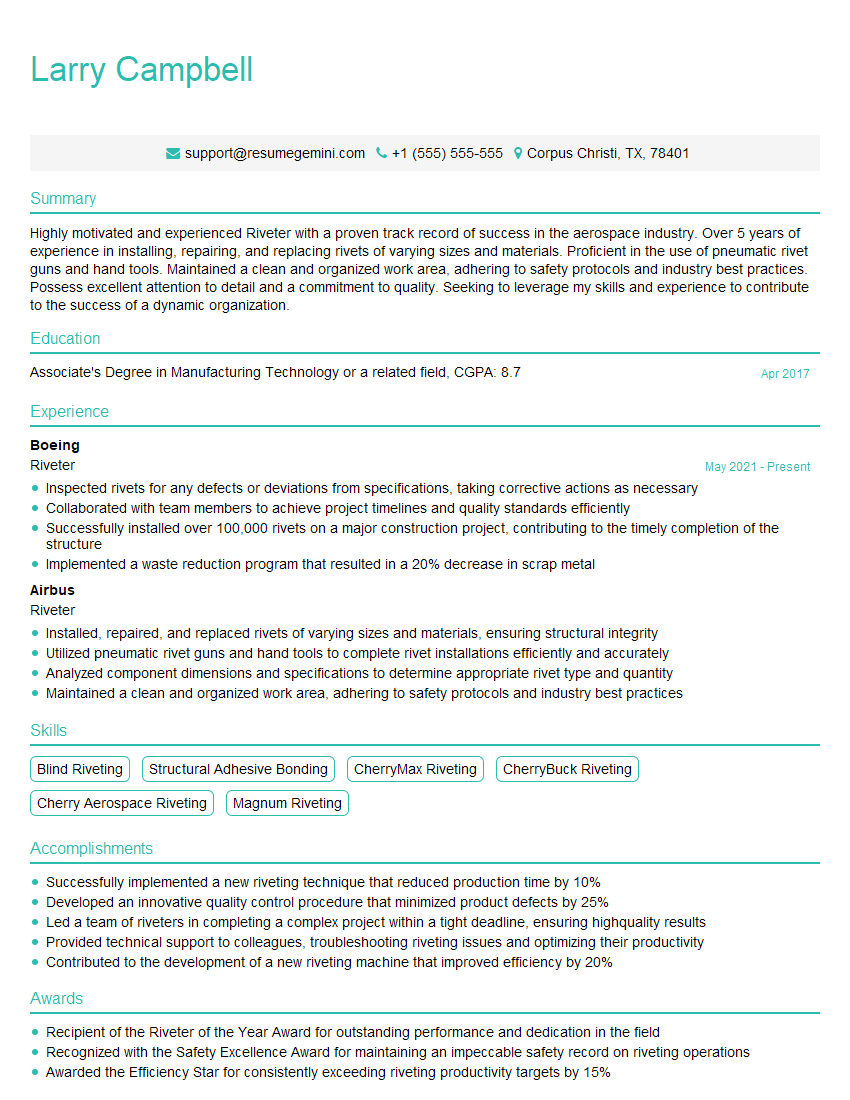

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Riveter

1. Can you explain the process of hole formation in riveting?

In the riveting process, holes are formed using a punch and die. The punch, which is a hardened steel tool, is forced through the workpiece, creating a hole. The die, which is a hardened steel block, supports the workpiece and prevents it from tearing. The size and shape of the hole is determined by the punch and die.

2. What are the different types of rivet heads?

Flat head

- Countersunk head

- Oval head

Round head

- Pan head

- Button head

3. What are the advantages and disadvantages of using rivets?

- Advantages

- Strong and durable joints

- Easy to install

- Can be used in a variety of applications

- Disadvantages

- Can be difficult to remove

- Can create a protrusion on the surface of the workpiece

4. What is the difference between a solid rivet and a tubular rivet?

- Solid rivets are made from a single piece of metal, while tubular rivets are made from two pieces of metal. The tubular rivet has a hollow center, which makes it lighter and easier to install.

- Solid rivets are stronger than tubular rivets, but tubular rivets are more versatile and can be used in a wider range of applications.

5. What are the different types of riveting machines?

- Manual riveting machines

- Pneumatic riveting machines

- Hydraulic riveting machines

- Electric riveting machines

6. What are the safety precautions that should be taken when using a riveting machine?

- Always wear eye protection.

- Wear gloves to protect your hands.

- Keep your hair and clothing away from the moving parts of the machine.

- Do not operate the machine if it is damaged.

- Follow the manufacturer’s instructions for operating the machine.

7. What are the common problems that can occur when riveting?

- Buckling of the workpiece

- Fracture of the rivet

- Loose rivets

- Misaligned rivets

8. How do you inspect a riveted joint?

- Visually inspect the joint for any cracks, gaps, or other defects.

- Use a hammer to tap the rivets and listen for any loose or broken rivets.

- Use a dye penetrant test to identify any cracks or other defects in the joint.

9. What are the applications of riveting?

- Aircraft construction

- Automotive manufacturing

- Construction

- Shipbuilding

10. What is the future of riveting?

Riveting is a mature technology that has been used for centuries. However, there are a number of new developments that are making riveting more efficient and versatile.

- New riveting machines are being developed that are faster, more powerful, and more accurate than previous machines.

- New rivet materials are being developed that are stronger, lighter, and more corrosion-resistant than traditional rivet materials.

- New riveting techniques are being developed that are making it possible to rivet a wider range of materials.

These developments are making riveting an increasingly attractive option for a variety of applications.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Riveter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Riveter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Riveter is a skilled professional responsible for assembling and joining materials using rivets, bolts, and other fasteners. They work in various industries, including construction, manufacturing, and transportation.

1. Riveting and Assembly

Riveters primarily use riveting guns or presses to insert rivets through holes in metal or other materials. They ensure that the rivets are properly seated and secure to create strong and durable joints.

- Operate riveting guns or presses to insert rivets into materials.

- Align and position materials for riveting operations.

- Use appropriate riveting techniques to ensure secure and durable joints.

2. Metalworking and Fabrication

Riveters often work with metal components and may perform basic metalworking tasks such as drilling, cutting, and bending. They may also assist in the fabrication of metal structures and components.

- Drill holes for rivets using drill presses or power tools.

- Cut and shape metal components using saws, shears, or other tools.

- Assemble and fabricate metal structures and components.

3. Quality Control and Inspection

Riveters are responsible for maintaining quality standards in their work. They inspect completed joints and assemblies to ensure they meet specifications and requirements.

- Inspect rivets and joints for defects or imperfections.

- Use measuring tools and gauges to verify dimensions and tolerances.

- Report any quality issues or deviations to supervisors or quality control personnel.

4. Safety and Maintenance

Riveters prioritize safety in their work environment and are responsible for maintaining their equipment. They follow established safety protocols, wear appropriate safety gear, and handle hazardous materials with care.

- Follow safety regulations and procedures for riveting operations.

- Wear appropriate safety gear, including gloves, eye protection, and hearing protection.

- Inspect and maintain riveting equipment regularly to ensure proper functionality.

Interview Tips

To ace the interview for a Riveter position, it’s essential to prepare thoroughly and present yourself confidently. Here are some tips and hacks to help you make a positive impression:

1. Research the Company and Position

Research the company you’re applying to and the specific Riveter position. This will help you understand the company culture, values, and the requirements of the role. You can visit the company website, read industry publications, and connect with employees on LinkedIn.

2. Highlight Your Skills and Experience

In your resume and interview, emphasize your skills and experience that are relevant to the Riveter position. This includes your proficiency in riveting techniques, metalworking, and quality control. Quantify your accomplishments with specific examples and metrics to demonstrate your impact.

3. Practice Common Interview Questions

Anticipate common interview questions and prepare your answers in advance. This will help you feel more confident and articulate during the interview. Practice answering questions about your experience, skills, and why you’re interested in the position.

4. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows that you’re engaged and interested in the opportunity. Prepare questions about the company, the position, or the industry to demonstrate your enthusiasm and curiosity.

5. Follow Up and Thank You

After the interview, send a thank-you note to the interviewer within 24 hours. In the note, reiterate your interest in the position, thank them for their time, and briefly highlight your key qualifications. This will leave a positive impression and serve as a reminder of your candidacy.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Riveter, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Riveter positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.