Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Curb Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

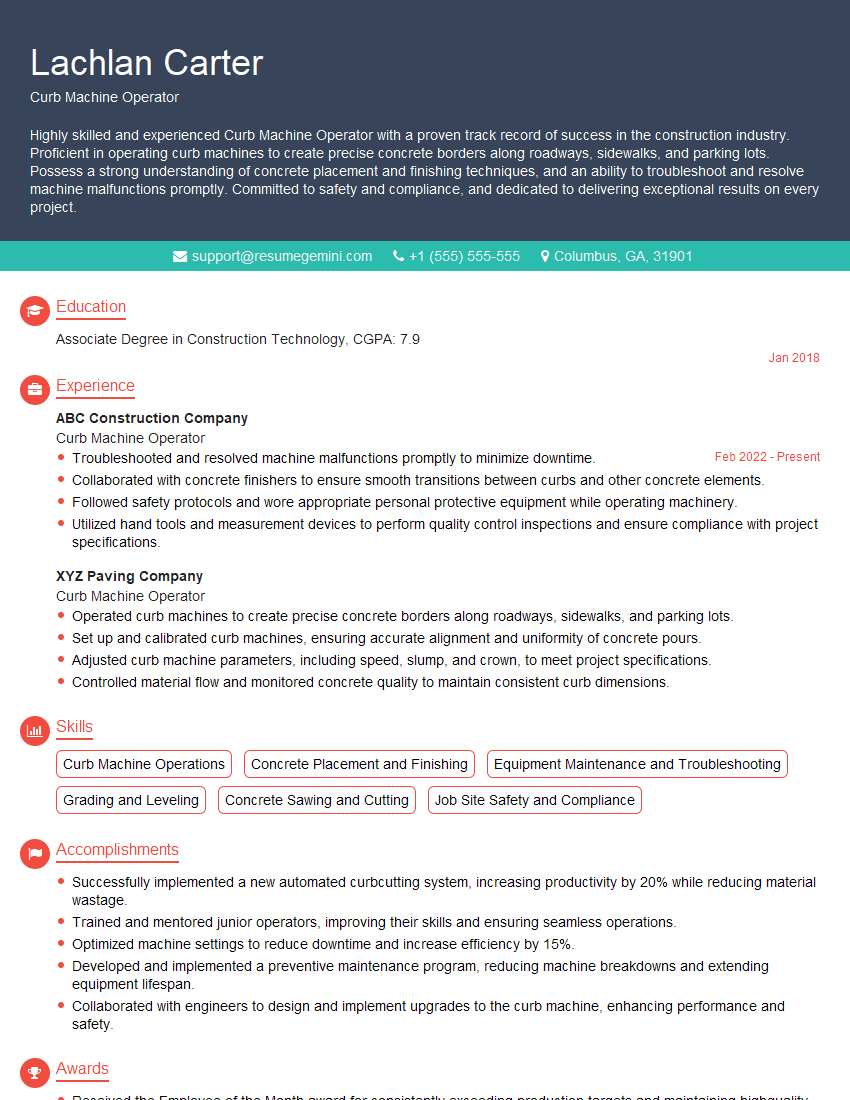

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Curb Machine Operator

1. What is the purpose of a curb machine?

A curb machine is used to create concrete curbs for roads, sidewalks, and other paved areas. It is a self-propelled machine which consist of a mold, a hopper, vibrators, screed and a conveyor belt to transport wet concrete from the hopper to the mold.

2. What are the different types of curb machines?

Slip-form

- Uses a mold that is continuously moved forward as the concrete is placed, creating a continuous curb.

Extrusion

- Uses a mold that is filled with concrete and then extruded through a die, creating a curb of a specific shape.

Pressurized

- Uses a pressurized system to force concrete into a mold, creating a curb with a high compressive strength.

3. What are the key operating principles of a curb machine?

The key operating principles of a curb machine include:

- Materials Handling: Loading and transporting wet concrete from the transit mixer to the hopper of the curb machine.

- Molding: Shaping the concrete into the desired curb profile using a mold.

- Vibration: Using vibrators to remove air bubbles and consolidate the concrete.

- Extrusion/Slip-forming: Extruding or slip-forming the concrete to create the curb.

- Finishing: Smoothing and texturing the surface of the curb using a screed or finishing tools.

- Curing: Ensuring proper curing conditions for the concrete to gain strength.

4. What are the different types of concrete used in curb construction?

The different types of concrete used in curb construction include:

- Normal Strength Concrete (NSC): Used for low-traffic areas, sidewalks, and non-critical applications.

- High-Strength Concrete (HSC): Used for high-traffic areas, roads, and critical applications where higher strength and durability are required.

- Reinforced Concrete: Used when additional strength and resistance to cracking are required. Steel reinforcement is added to the concrete mix.

5. What are the safety precautions to be taken while operating a curb machine?

- Proper Training and Certification: Operators must be trained and certified to operate the curb machine.

- Personal Protective Equipment (PPE): Wearing appropriate PPE such as hard hats, safety glasses, gloves, and proper clothing.

- Jobsite Safety: Ensuring a safe jobsite by identifying and mitigating hazards, controlling access, and following safety protocols.

- Electrical Safety: Ensuring proper electrical connections, grounding, and avoiding contact with overhead power lines.

- Concrete Handling: Following proper procedures for loading, transporting, and placing concrete, including safe handling of wet concrete.

- Machine Operation: Operating the curb machine in accordance with manufacturer’s instructions, conducting regular inspections, and maintaining the equipment properly.

- Emergency Procedures: Knowing and following emergency procedures in case of accidents, breakdowns, or other unforeseen events.

6. What are the common maintenance tasks required for a curb machine?

- Regular Inspections: Daily or weekly inspections to check for any wear and tear, loose connections, or potential issues.

- Cleaning: Cleaning the machine after each use to remove concrete residue, debris, and dirt.

- Lubrication: Greasing and lubricating moving parts according to manufacturer’s recommendations.

- Mold Maintenance: Inspecting, cleaning, and repairing the curb mold as needed to ensure proper curb formation.

- Electrical Checks: Checking electrical connections, wires, and components for any damage or loose connections.

- Tire and Track Care: Maintaining proper tire pressure or track tension, and inspecting for wear or damage.

- Engine Maintenance: Following the manufacturer’s maintenance schedule for engine oil changes, filter replacements, and other necessary services.

7. How do you troubleshoot common problems with a curb machine?

- Concrete Not Flowing Properly: Check concrete mix, inspect for blockages in the conveyor belt or hopper, and ensure proper vibration.

- Curb Not Forming Correctly: Inspect the mold for damage or misalignment, check the screed settings, and adjust the extrusion or slip-forming process.

- Engine Problems: Refer to the engine manufacturer’s guidelines for troubleshooting, check fuel levels, spark plugs, and other components.

- Hydraulic Issues: Check hydraulic fluid levels, inspect hoses and connections for leaks or damage, and ensure proper operation of pumps and valves.

- Electrical Faults: Check electrical connections, fuses, and switches, and refer to electrical schematics for further troubleshooting.

8. What are the quality control measures for curb construction?

- Concrete Testing: Conducting slump tests, air content tests, and strength tests to ensure concrete meets specifications.

- Mold Inspection: Verifying the mold is clean, properly aligned, and producing curbs that meet dimensional and shape requirements.

- Curing and Finishing: Ensuring proper curing conditions, monitoring temperature and moisture, and finishing the curb surface to meet smoothness and texture standards.

- Dimensional Checks: Measuring curb height, width, and alignment to ensure compliance with project plans and specifications.

- Visual Inspection: Checking for cracks, voids, honeycombing, or other defects that may affect curb performance or aesthetics.

9. How do you ensure the safety of workers and the public during curb construction?

- Site Preparation: Securing the work area, setting up barricades, and providing proper lighting.

- Traffic Control: Implementing traffic management plans, using flagmen, and coordinating with local authorities.

- PPE Enforcement: Ensuring workers wear appropriate personal protective equipment, including hard hats, safety glasses, gloves, and high-visibility clothing.

- Hazard Identification and Mitigation: Identifying potential hazards and taking steps to minimize risks, such as controlling dust, managing wet surfaces, and providing proper ventilation.

- Emergency Preparedness: Having emergency response plans in place, including first aid kits, fire extinguishers, and contact information for medical assistance.

10. How do you stay up-to-date on the latest industry trends and best practices for curb machine operation?

- Industry Publications: Reading trade magazines, journals, and technical articles related to concrete construction and curb machine operation.

- Conferences and Seminars: Attending industry events, conferences, and seminars to learn about new technologies, techniques, and regulations.

- Online Resources: Utilizing online forums, technical websites, and manufacturer resources to access up-to-date information and best practices.

- Training Programs: Participating in manufacturer-provided training programs or specialized courses to enhance skills and knowledge.

- Collaboration with Peers: Sharing knowledge and experiences with other curb machine operators, contractors, and industry professionals.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Curb Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Curb Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Curb Machine Operator is responsible for the operation of the curb-making machine to produce concrete curbs or gutters required for roadway and sidewalk construction. Duties and responsibilities include:

1. Machine Operation

Ensures the curb-making machine is operational, safe, and ready for production.

- Perform daily inspections and maintenance on the machine.

- Monitor machine performance and make adjustments to the equipment as needed.

- Troubleshoot and resolve operational problems promptly.

2. Production and Quality Control

Manages the production process to meet project specifications and maintain high-quality standards.

- Control the flow of concrete into the mold to ensure the desired shape and size of the curb or gutter.

- Monitor and adjust the smoothness, texture, and alignment of the finished product.

- Make corrections or repairs to the finished product as necessary.

3. Safety and Compliance

Follows established safety protocols and ensures compliance with all applicable regulations.

- Wear protective gear and observe all safety procedures.

- Prevent accidents and maintain a safe work environment.

- Comply with environmental regulations and ensure proper disposal of waste materials.

4. Communication and Coordination

Maintains effective communication with colleagues and supervisors to ensure smooth project execution.

- Communicate any machine issues or production delays promptly.

- Coordinate with other crew members and equipment operators.

- Follow instructions from supervisors and adapt to changes in the project scope.

Interview Tips

To help you ace your Curb Machine Operator interview, here are a few tips to keep in mind:

1. Research the Company and Position

Take the time to research the company and the specific position you’re applying for. This will show that you’re genuinely interested in the opportunity and have taken the time to learn more about the company’s culture and goals.

- Visit the company’s website and social media pages.

- Read industry news and articles about the company.

- Connect with current or former employees on LinkedIn.

2. Prepare for Common Interview Questions

Familiarize yourself with common interview questions and practice your answers. This will help you feel more confident and prepared during the interview.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- Tell me about your experience operating curb-making machines.

- How do you handle working in a fast-paced environment?

- What are your salary expectations?

3. Highlight Your Skills and Experience

In your interview, emphasize your skills and experience that are relevant to the Curb Machine Operator position. Be specific and provide examples to support your claims.

- Highlight your experience in operating curb-making machines.

- Showcase your ability to maintain and troubleshoot equipment.

- Emphasize your commitment to safety and compliance.

- Demonstrate your communication and coordination skills.

4. Ask Questions

Asking thoughtful questions at the end of the interview shows that you’re engaged and interested in the opportunity. It also gives you a chance to gather more information about the position and the company.

- What are the company’s goals for this position?

- What are the biggest challenges facing the company right now?

- What opportunities for professional development are available?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Curb Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!