Are you gearing up for an interview for a Hydraulic Press-In Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Hydraulic Press-In Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

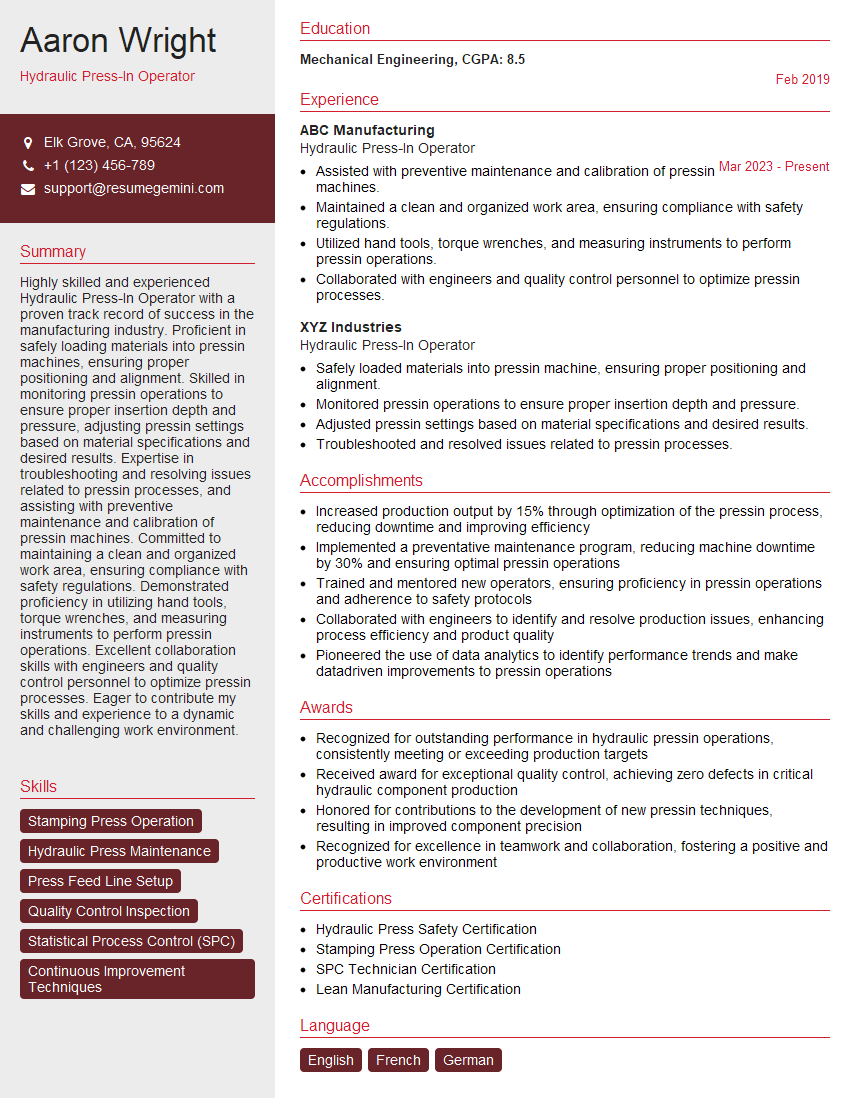

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hydraulic Press-In Operator

1. Explain the function and working principle of a hydraulic press?

A hydraulic press is a machine that uses the principle of Pascal’s law to generate a large force by applying a smaller force to a piston within a cylinder. The basic working principle involves the following steps:

- Pascal’s Law: The pressure applied at any point in a confined fluid is transmitted equally throughout the entire fluid.

- Force Multiplication: When a smaller force is applied to a smaller piston connected to a larger piston, the force is multiplied by the ratio of the piston areas.

- Hydraulic Circuit: A hydraulic press consists of a hydraulic circuit, including a reservoir, pump, cylinders, and valves. The pump generates pressure and forces hydraulic fluid into the cylinder with the larger piston.

- Pressing Operation: The increased pressure on the larger piston results in a magnified force that presses the object placed between the piston and the stationary platen.

2. What are the different types of hydraulic presses?

- Benchtop Hydraulic Press: Designed for smaller applications, typically used for crimping, punching, and assembling.

- Floor-Standing Hydraulic Press: Provides greater force and capacity, suitable for larger industrial applications such as forming, bending, and testing.

- C-Frame Hydraulic Press: Offers high rigidity and stability, often used for precision machining operations, such as cutting and stamping.

- Gap-Frame Hydraulic Press: Provides a large working area and allows for easy loading and unloading of workpieces.

- Custom Hydraulic Presses: Designed to meet specific requirements, such as high tonnage, automation, or specialized press operations.

3. What are the key components of a hydraulic press system?

- Hydraulic Reservoir: Stores the hydraulic fluid and provides a place for air separation, cooling, and filtration.

- Pump: Generates pressure within the hydraulic circuit by moving fluid.

- Cylinders: Convert hydraulic pressure into linear force, moving pistons to exert force on the workpiece.

- Valves: Control the flow and direction of hydraulic fluid, allowing precise control of press motion.

- Piping and Fittings: Connect the components of the hydraulic system, ensuring fluid flow and maintaining pressure.

- Control System: Monitors and regulates the system, including pressure, temperature, and speed.

4. How do you troubleshoot common hydraulic press problems?

- Low Pressure: Check fluid level, filters, pump operation, and valve settings.

- Leaks: Inspect hoses, fittings, seals, and cylinders for any signs of leakage.

- Overheating: Check fluid temperature, filter condition, and cooling systems.

- Sluggish Operation: Verify pump performance, valve operation, and cylinder piston movement.

- Excessive Noise: Inspect pump gears, valves, and bearings for wear or damage.

5. How do you maintain a hydraulic press to ensure optimal performance?

- Regular Fluid Changes: Replace hydraulic fluid as per manufacturer’s recommendations to remove contaminants and maintain fluid quality.

- Filter Maintenance: Inspect and clean filters regularly to remove particles and prevent system contamination.

- Valve Checks: Inspect and adjust valves as needed to ensure proper flow and pressure control.

- Cylinder Inspection: Monitor cylinder seals, piston condition, and alignment for any signs of wear or damage.

- Leak Monitoring: Regularly inspect hoses, fittings, and seals for any leaks and address them promptly.

- Preventative Maintenance: Schedule regular inspections and maintenance to identify potential issues and prevent breakdowns.

6. What safety precautions should be followed when operating a hydraulic press?

- PPE: Always wear appropriate personal protective equipment, including safety glasses, gloves, and hearing protection.

- Work Area: Ensure the work area is clear of obstacles and distractions.

- Guarding: Use guards and barriers to protect against moving parts and potential hazards.

- Pressure Monitoring: Monitor pressure gauges and never exceed the manufacturer’s specifications.

- Lockout/Tagout: Follow proper lockout/tagout procedures before performing maintenance or repairs.

- Emergency Stop: Be familiar with the emergency stop button and use it if necessary.

7. How do you perform critical dimension measurements and ensure accuracy on parts produced using a hydraulic press?

- Calibration: Calibrate measuring equipment regularly to ensure accuracy.

- Precision Tools: Use high-precision measuring tools, such as calipers, micrometers, or CMMs.

- Reference Points: Establish clear reference points on the part and use them for consistent measurements.

- Multiple Measurements: Take multiple measurements at different points to ensure accuracy.

- Environmental Control: Maintain stable environmental conditions in the measurement area to avoid temperature fluctuations that can affect accuracy.

- Operator Training: Train operators on proper measuring techniques and the importance of accuracy.

8. What are the key factors that determine the tonnage capacity of a hydraulic press?

- Cylinder Diameter: The diameter of the hydraulic cylinder determines the force it can generate.

- Operating Pressure: The maximum pressure supplied to the cylinder influences the force output.

- Material Strength: The strength of the materials used in the press, including the cylinder, frame, and platens, impacts the tonnage capacity.

- Design Configuration: The geometric arrangement of the press, such as C-frame or gap-frame, can affect load distribution and tonnage capacity.

9. How do you calculate the tonnage required for a specific pressing operation?

- Material Yield Strength: Determine the yield strength of the material being pressed.

- Contact Area: Estimate the surface area of the material in contact with the press platens.

- Required Force: Multiply the yield strength by the contact area to calculate the force required.

- Tonnage: Convert the force to tonnage by dividing by 2000 (1 ton = 2000 lbs).

10. How do you optimize productivity on a hydraulic press?

- Job Sequencing: Plan the sequence of operations to minimize setup time and improve efficiency.

- Tooling Setup: Ensure proper tooling setup and alignment to reduce cycle times.

- Automated Loading and Unloading: Consider automation to streamline material handling and reduce manual labor.

- Maintenance and Calibration: Regular maintenance and calibration ensure optimal press performance and prevent breakdowns.

- Operator Training: Provide training to operators on proper operating techniques and safety protocols to improve efficiency and safety.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hydraulic Press-In Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hydraulic Press-In Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Hydraulic Press-In Operators are responsible for operating hydraulic presses to press parts together. They may also be responsible for setting up and maintaining the press, as well as inspecting and testing parts.

1. Operating the hydraulic press

Hydraulic Press-In Operators are responsible for operating the hydraulic press to press parts together. They must be able to follow instructions and operate the press safely and efficiently.

- Follow instructions on work orders to set up and operate the hydraulic press.

- Load and unload parts from the press.

- Monitor the press during operation to ensure that it is functioning properly.

- Adjust the press settings as needed to ensure that the parts are pressed together correctly.

2. Setting up and maintaining the press

Hydraulic Press-In Operators are also responsible for setting up and maintaining the press. They must be able to troubleshoot and repair minor problems, as well as perform preventive maintenance.

- Set up the press according to the manufacturer’s instructions.

- Lubricate and clean the press as needed.

- Inspect the press for wear and tear, and make repairs as needed.

- Perform preventive maintenance on the press to ensure that it is operating properly.

3. Inspecting and testing parts

Hydraulic Press-In Operators are also responsible for inspecting and testing parts. They must be able to identify defects and ensure that the parts meet specifications.

- Inspect parts for defects before and after pressing.

- Test parts to ensure that they meet specifications.

- Reject parts that do not meet specifications.

Interview Tips

Preparing for an interview can be daunting, but there are a few things you can do to increase your chances of success.

1. Research the company

Before you go to your interview, take some time to research the company. This will help you understand their business, their culture, and the position you are applying for.

- Visit the company’s website.

- Read articles about the company in the news.

- Talk to people who work for the company.

2. Practice answering common interview questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice answering these questions in advance so that you can deliver your answers confidently and concisely.

- Make a list of common interview questions.

- Practice answering the questions out loud.

- Get feedback from a friend or family member.

3. Dress professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the office environment.

- Choose clothes that are comfortable and allow you to move freely.

- Avoid wearing clothes that are too revealing or too casual.

- Make sure your clothes are clean and pressed.

4. Be on time

Punctuality is important, so be sure to arrive for your interview on time. If you are running late, call or email the interviewer to let them know.

- Plan your route to the interview in advance.

- Leave early to give yourself plenty of time to get there.

- If you are running late, call or email the interviewer to let them know.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Hydraulic Press-In Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!