Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Diesel Pile Hammer Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

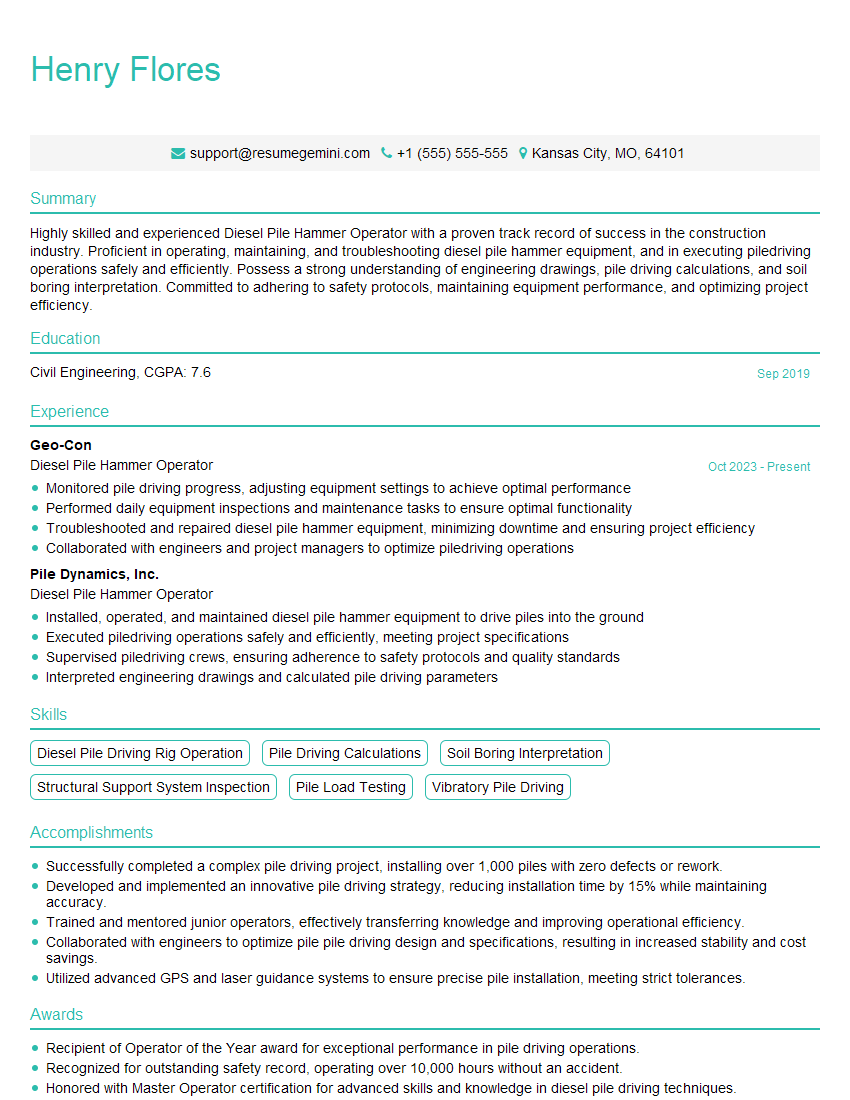

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Diesel Pile Hammer Operator

1. What are the key components of a diesel pile hammer and how do they function?

- Anvil: A heavy metal block that supports the pile being driven.

- Ram: A large, cylindrical weight that is raised and dropped by the hammer.

- Engine: Provides power to raise and drop the ram.

- Hydraulic system: Controls the movement of the ram.

- Fuel injection system: Delivers fuel to the engine.

2. How do you determine the appropriate energy level for a particular pile driving application?

Factors to consider:

- Pile material and size

- Soil conditions

- Required pile penetration depth

Procedure:

- Perform soil tests to determine soil bearing capacity.

- Calculate the required pile capacity using engineering formulas.

- Select a pile hammer with an energy rating that exceeds the required pile capacity.

3. Describe the proper safety procedures for operating a diesel pile hammer.

- Wear proper PPE, including hard hat, safety glasses, gloves, and earplugs.

- Inspect the hammer and pile driving equipment before each use.

- Clear the work area of any personnel or obstacles.

- Operate the hammer from a safe distance.

- Be aware of the hammer’s swing radius.

4. How do you troubleshoot common problems with diesel pile hammers?

- Engine won’t start: Check fuel supply, electrical system, and battery.

- Ram fails to drop: Check hydraulic system, fuel injection system, and air filter.

- Excessive vibration: Check anvil, ram, and guide rods for wear or damage.

- Hammer stalls: Check fuel quality, air filter, and engine performance.

5. How do you maintain and inspect diesel pile hammers?

- Daily: Check fuel and oil levels, inspect hoses and connections for leaks, and clean the hammer housing.

- Weekly: Perform a more thorough inspection, including checking the anvil, ram, guide rods, and hydraulic system.

- Monthly: Lubricate all moving parts and perform a comprehensive system check.

- Annually: Have the hammer inspected and serviced by a qualified technician.

6. What are the different types of pile driving configurations and when are they used?

- Single-acting: Ram is raised by hydraulic pressure and falls under gravity.

- Double-acting: Ram is raised and dropped by hydraulic pressure.

- Drop hammer: Ram is lifted by a crane and dropped freely.

- Vibratory hammer: Pile is driven using high-frequency vibrations.

- Sonic pile driver: Pile is driven using resonant frequencies.

7. How do you calculate the pile driving formula?

- Diesel pile driving formula: E = P x S x N

- E: Energy of the pile hammer (ft-lbs)

- P: Pile weight (tons)

- S: Stroke of the ram (ft)

- N: Number of blows per minute

8. What are the potential hazards associated with pile driving and how can they be mitigated?

- Noise: Use earplugs or earmuffs.

- Vibration: Use anti-vibration gloves or tools.

- Falling objects: Wear a hard hat and stay clear of overhead hazards.

- Pinch points: Be aware of moving parts and keep hands clear.

- Eye injuries: Wear safety glasses or goggles.

9. How do you ensure pile integrity during driving?

- Use a pile integrity tester to monitor the pile’s response to hammer blows.

- Observe the pile’s behavior during driving for any signs of damage or distress.

- Conduct pile load tests to verify the pile’s load-bearing capacity.

10. How do you stay up-to-date with the latest advancements in pile driving technology?

- Attend industry conferences and seminars.

- Read trade publications and technical journals.

- Consult with manufacturers and suppliers.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Diesel Pile Hammer Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Diesel Pile Hammer Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Diesel Pile Hammer Operators are responsible for the safe and efficient operation of diesel pile hammers, which are used to drive piles into the ground to support structures such as bridges and buildings. Key job responsibilities include:

1. Operating the diesel pile hammer

This involves setting up the hammer, starting it, and controlling its operation. Operators must be able to monitor the hammer’s performance and make adjustments as needed to ensure that it is driving the piles to the correct depth and at the correct angle.

- Setting up the hammer, including assembling the frame and attaching the hammer to the pile.

- Starting the hammer and controlling its operation, including adjusting the fuel flow and air pressure.

- Monitoring the hammer’s performance, including the stroke rate, fuel consumption, and air pressure.

- Making adjustments to the hammer’s operation as needed to ensure that it is driving the piles to the correct depth and at the correct angle.

2. Maintaining the diesel pile hammer

This involves performing regular maintenance tasks such as checking the oil level, changing the air filter, and greasing the bearings. Operators must also be able to troubleshoot and repair minor problems with the hammer.

- Performing regular maintenance tasks, such as checking the oil level, changing the air filter, and greasing the bearings.

- Troubleshooting and repairing minor problems with the hammer, such as fuel leaks and air leaks.

3. Ensuring the safety of the work area

This involves following all safety procedures and wearing the appropriate safety gear. Operators must also be aware of the potential hazards associated with operating a diesel pile hammer and take steps to minimize the risks.

- Following all safety procedures, such as wearing the appropriate safety gear and following the manufacturer’s instructions for operating the hammer.

- Being aware of the potential hazards associated with operating a diesel pile hammer, such as the risk of fire, explosion, and injury from moving parts.

- Taking steps to minimize the risks, such as keeping the work area clear of debris and using proper lifting techniques when handling heavy objects.

4. Working with other members of the construction crew

Diesel Pile Hammer Operators must be able to work effectively with other members of the construction crew, including laborers, carpenters, and engineers. They must be able to communicate clearly and follow instructions, and they must be willing to work as part of a team.

- Working effectively with other members of the construction crew, including laborers, carpenters, and engineers.

- Communicating clearly and following instructions.

- Being willing to work as part of a team.

Interview Tips

To ace an interview for a Diesel Pile Hammer Operator position, it is important to be prepared and to know what to expect. Here are some tips to help you prepare:

1. Research the company and the position

Take some time to learn about the company you are applying to and the specific position you are interested in. This will help you to understand the company’s culture and values, and it will also help you to tailor your answers to the interviewer’s questions.

- Visit the company’s website to learn about its history, mission, and values.

- Read the job description carefully to understand the specific requirements of the position.

- Talk to people who work for the company, if possible, to get their insights on the company culture and the position.

2. Practice answering common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice answering these questions in advance so that you can deliver your answers confidently and clearly.

- Use the STAR method (Situation, Task, Action, Result) to answer questions about your experience and skills.

- Be prepared to talk about your experience operating diesel pile hammers, as well as your knowledge of the industry and safety procedures.

- Be enthusiastic and positive in your answers, and be sure to highlight your skills and experience that are most relevant to the position.

3. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows the interviewer that you are serious about the position and that you respect their time.

- Dress in clean, pressed clothing that is appropriate for a construction environment.

- Arrive on time for your interview, or even a few minutes early.

4. Be yourself and be confident

The most important thing is to be yourself and to be confident in your abilities. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Be honest and authentic, and let your personality shine through.

- Be yourself and be confident in your abilities.

- Answer questions honestly and authentically.

- Let your personality shine through.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Diesel Pile Hammer Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Diesel Pile Hammer Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.