Feeling lost in a sea of interview questions? Landed that dream interview for Hydraulic Pile Hammer Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Hydraulic Pile Hammer Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

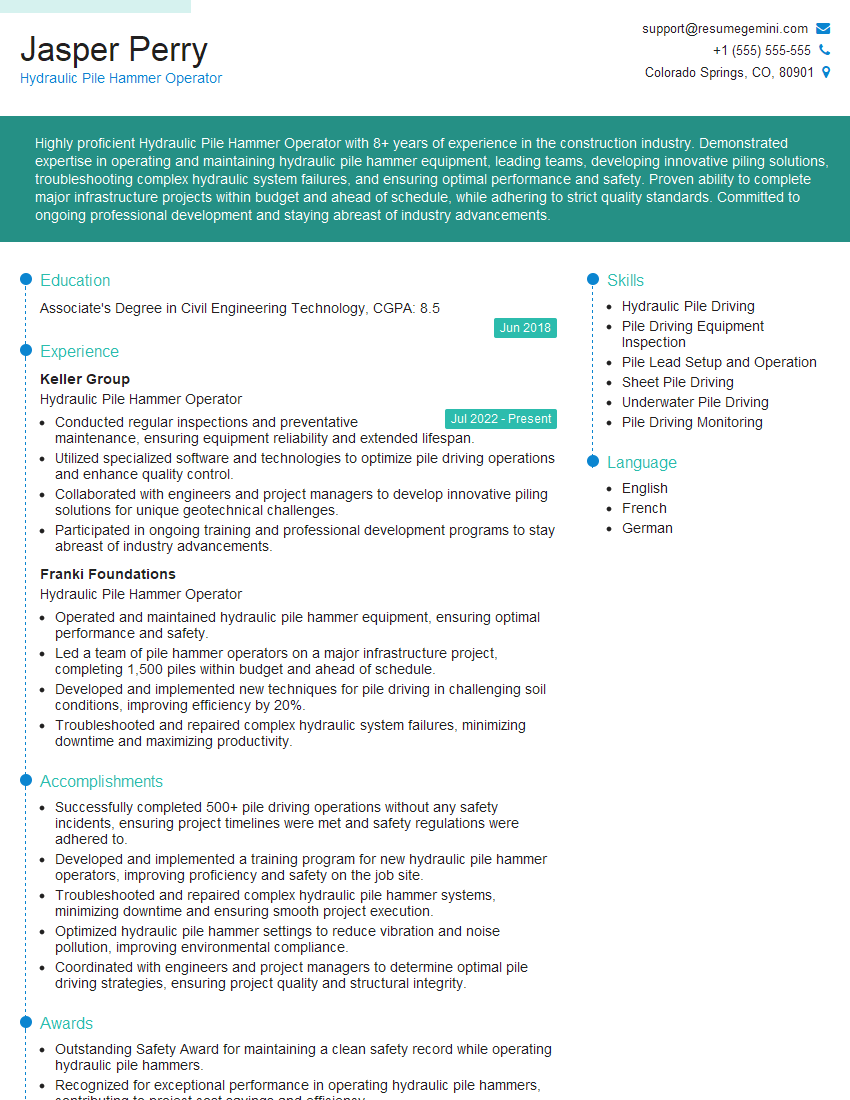

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hydraulic Pile Hammer Operator

1. Describe the key components of a hydraulic pile hammer and explain their functions.

The key components of a hydraulic pile hammer are:

- Ram: The ram is the heavy, cylindrical part of the hammer that strikes the pile.

- Piston: The piston is connected to the ram and moves up and down inside the cylinder.

- Cylinder: The cylinder is a tube that contains the piston and hydraulic fluid.

- Hydraulic fluid: The hydraulic fluid is a pressurized liquid that powers the hammer.

- Valve system: The valve system controls the flow of hydraulic fluid into and out of the cylinder.

2. What are the different types of hydraulic pile hammers?

Single-acting hammers

- Use hydraulic pressure to lift the ram and gravity to drive it down.

- Less efficient than double-acting hammers.

Double-acting hammers

- Use hydraulic pressure to both lift and drive the ram.

- More efficient than single-acting hammers.

3. How do you calculate the energy delivered by a hydraulic pile hammer?

The energy delivered by a hydraulic pile hammer is calculated using the following formula:

- E = 1/2 * m * v^2

- Where:

- E is the energy in joules

- m is the mass of the ram in kilograms

- v is the velocity of the ram in meters per second

4. What are the safety precautions that must be taken when operating a hydraulic pile hammer?

The following safety precautions must be taken when operating a hydraulic pile hammer:

- Ensure that the hammer is in good working condition.

- Wear appropriate safety gear, including hard hat, safety glasses, and gloves.

- Keep the work area clear of debris.

- Do not operate the hammer under the influence of drugs or alcohol.

- Follow the manufacturer’s instructions for operating the hammer.

5. What are the common maintenance tasks that need to be performed on a hydraulic pile hammer?

The following common maintenance tasks need to be performed on a hydraulic pile hammer:

- Inspect the hammer for any damage.

- Lubricate the moving parts.

- Check the hydraulic fluid level and top up as necessary.

- Replace any worn or damaged parts.

6. What are the troubleshooting steps that can be taken if a hydraulic pile hammer is not functioning properly?

The following troubleshooting steps can be taken if a hydraulic pile hammer is not functioning properly:

- Check the hydraulic fluid level.

- Check the hydraulic hoses for leaks.

- Check the valve system for any malfunctions.

- Check the ram and piston for any damage.

7. What are the different types of pile driving projects that you have worked on?

I have worked on a variety of pile driving projects, including:

- Bridge construction

- Building foundations

- Marine construction

- Offshore wind farm construction

8. What are the challenges that you have faced while working on pile driving projects?

I have faced a number of challenges while working on pile driving projects, including:

- Working in difficult weather conditions

- Working in confined spaces

- Driving piles into hard or rocky ground

- Ensuring that the piles are driven to the correct depth and alignment

9. What are the quality control measures that you follow when driving piles?

I follow a number of quality control measures when driving piles, including:

- Inspecting the piles before driving

- Monitoring the pile driving process

- Testing the piles after driving

- Maintaining a record of all pile driving activities

10. What are your career goals?

My career goals are to:

- Become a certified pile driving engineer

- Work on large-scale and complex pile driving projects

- Start my own pile driving company

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hydraulic Pile Hammer Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hydraulic Pile Hammer Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Hydraulic Pile Hammer Operators are highly skilled professionals responsible for the operation of hydraulic pile hammers used in construction projects. These individuals play a crucial role in ensuring that piles are driven into the ground safely and efficiently to provide a solid foundation for structures. Key job responsibilities include:

1. Operating Hydraulic Pile Hammers

Operators control hydraulic pile hammers, aligning them properly and driving them into the ground to the specified depth. They monitor the progress of pile driving, ensuring that it meets design specifications.

- Operate hydraulic pile hammers to drive piles into the ground.

- Monitor pile driving progress to ensure that it meets design specifications.

2. Equipment Maintenance and Inspection

Operators are responsible for maintaining and inspecting hydraulic pile hammers and related equipment. This includes checking fluid levels, inspecting hoses, and performing routine maintenance to ensure that equipment is operating safely and efficiently.

- Maintain and inspect hydraulic pile hammers and related equipment.

- Check fluid levels, inspect hoses, and perform routine maintenance.

3. Site Preparation and Layout

Operators assist in site preparation by clearing and leveling the area where piles will be driven. They also set up equipment and ensure that the work area is safe and secure.

- Assist in site preparation by clearing and leveling the area where piles will be driven.

- Set up equipment and ensure that the work area is safe and secure.

4. Safety Compliance

Operators are committed to adhering to safety regulations and protocols. They follow established procedures, wear appropriate safety gear, and take necessary precautions to minimize risks during pile driving operations.

- Adhere to safety regulations and protocols.

- Follow established procedures, wear appropriate safety gear, and take necessary precautions.

Interview Tips

Preparing for an interview as a Hydraulic Pile Hammer Operator requires thorough research and practice. Here are some valuable tips to help candidates ace the interview and showcase their skills:

1. Research the Company and Industry

Candidates should thoroughly research the company they are applying to, including its history, projects, and industry reputation. Understanding the company’s culture and values will demonstrate interest and alignment with the organization.

- Visit the company’s website and social media pages.

- Read industry news and articles to stay informed about trends and advancements.

2. Highlight Relevant Skills and Experience

Emphasize skills and experience that directly relate to the job responsibilities. Quantify accomplishments whenever possible to demonstrate the impact of contributions. Use specific examples to illustrate proficiency in hydraulic pile hammer operation, equipment maintenance, and safety compliance.

- Describe previous projects where you successfully operated hydraulic pile hammers.

- Provide examples of how you maintained and inspected equipment to ensure optimal performance.

3. Prepare for Common Interview Questions

Anticipate and prepare for common interview questions related to hydraulic pile hammer operation, safety, and industry knowledge. Practice answering these questions clearly and concisely, highlighting your expertise and enthusiasm for the role.

- Explain the principles of hydraulic pile hammer operation.

- Describe the importance of safety protocols in pile driving operations.

4. Ask Thoughtful Questions

Asking thoughtful questions during the interview demonstrates engagement and interest in the position. Prepare questions that delve deeper into the company’s projects, industry challenges, and opportunities for professional growth. This shows initiative and a desire to contribute to the organization’s success.

- Ask about the company’s current and upcoming projects.

- Inquire about the opportunities for professional development and training.

Next Step:

Now that you’re armed with the knowledge of Hydraulic Pile Hammer Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Hydraulic Pile Hammer Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini