Feeling lost in a sea of interview questions? Landed that dream interview for Road Roller Engineer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Road Roller Engineer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

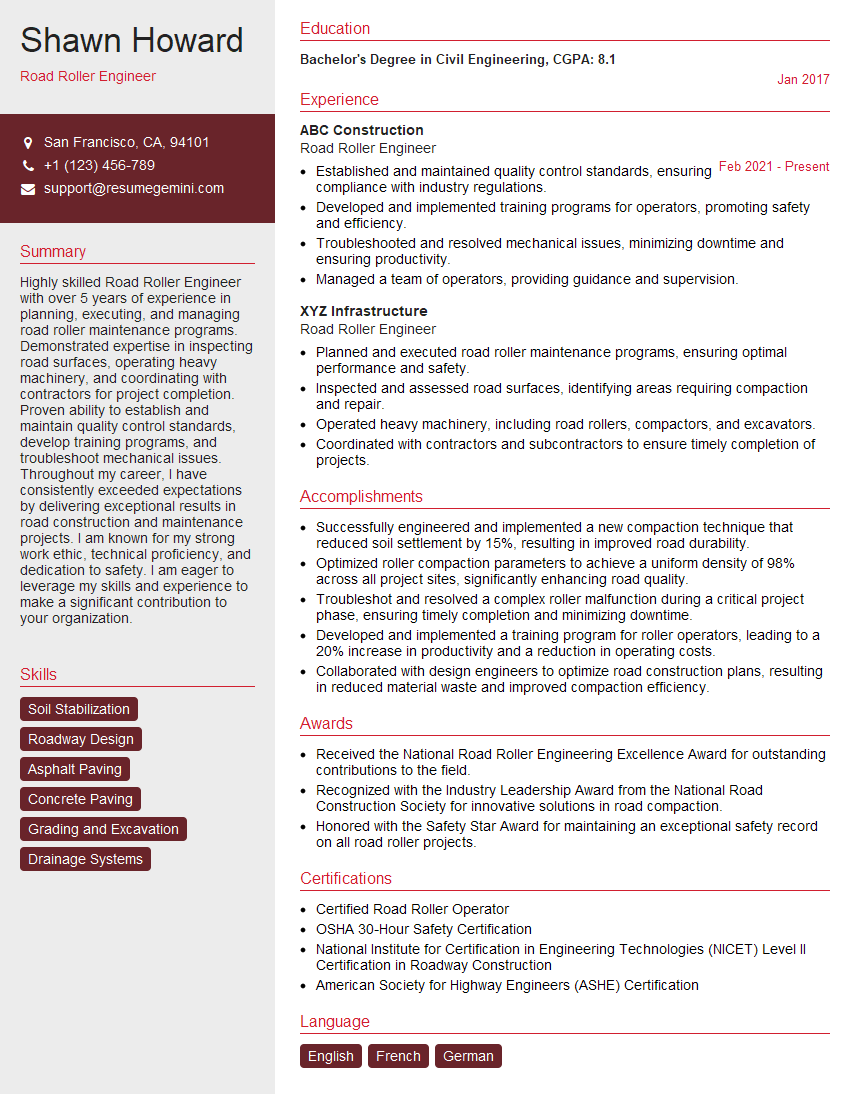

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Road Roller Engineer

1. What are the different types of road rollers and their applications?

- Static rollers: Used for compacting granular materials like sand and gravel, and for preparing subgrades.

- Vibratory rollers: Used for compacting various soil types and asphalt pavements.

- Pneumatic rollers: Used for compacting asphalt pavements and for providing a smooth finish.

- Tandem rollers: Used for compacting narrow areas and for providing a smooth finish.

- Three-wheel rollers: Used for compacting embankments, slopes, and other areas with limited access.

2. Explain the factors that affect the compaction process.

Soil characteristics:

- Soil type

- Moisture content

- Density

Roller characteristics:

- Roller weight

- Roller speed

- Roller vibration frequency and amplitude

3. What are the quality control procedures for road compaction?

- Field density tests: To determine the achieved compaction level.

- Nuclear density tests: To provide a rapid and non-destructive measurement of compaction.

- Proof rolling: To identify areas of weak or uneven compaction.

- Visual inspection: To assess the surface finish and smoothness of the compacted road.

4. What are the safety regulations for operating road rollers?

- Wear appropriate PPE: Safety helmet, safety glasses, and hearing protection.

- Inspect the roller before operation: Check for any defects or leaks.

- Maintain a safe distance from other workers: Never allow anyone to walk behind the roller.

- Be aware of your surroundings: Pay attention to overhead hazards and oncoming traffic.

- Follow all manufacturer’s instructions: Refer to the operator’s manual for specific safety guidelines.

5. How do you maintain and troubleshoot road rollers?

- Regular maintenance:

- Lubricate moving parts.

- Check fluid levels.

- Inspect tires and replace as needed.

- Calibrate and test the compaction system.

- Troubleshooting:

- Engine problems: Check fuel system, ignition system, and electrical connections.

- Compaction problems: Check roller weight, vibration system, and soil conditions.

- Hydraulic problems: Check hydraulic fluid levels, hoses, and pumps.

6. What are the environmental considerations in road roller operation?

- Minimize noise and vibration: Use vibration isolation and soundproofing measures.

- Control dust emissions: Use water spray systems or enclosed cabs.

- Prevent spills and leaks: Maintain vehicles and equipment in good condition.

- Dispose of used fluids and filters properly: Recycle or dispose of fluids according to regulations.

7. What are the future trends in road roller technology?

- Automated compaction control systems: To improve compaction accuracy and efficiency.

- Electric and hybrid rollers: To reduce emissions and noise pollution.

- Integrated GPS and mapping systems: To optimize roller operation and record compaction data.

- Telematics and remote monitoring systems: To track roller location, performance, and maintenance needs.

8. How do you stay updated on the latest road roller technology and best practices?

- Attend industry conferences and exhibitions.

- Read trade publications and technical journals.

- Participate in online forums and discussions.

- Consult with manufacturers and industry experts.

9. What are your strengths and weaknesses as a Road Roller Engineer?

Strengths:

- Excellent understanding of road construction principles and materials.

- Proficient in operating and maintaining road rollers.

- Strong attention to detail and quality.

- Ability to work independently and as part of a team.

Weaknesses:

- Limited experience with the latest automated compaction control systems.

- Working under tight deadlines can sometimes be stressful.

10. Why should we hire you as a Road Roller Engineer?

- I have extensive experience operating and maintaining road rollers in various projects.

- I am committed to delivering high-quality compaction results, ensuring the longevity of road infrastructure.

- I am eager to embrace new technologies and contribute to the advancement of road roller engineering.

- I am confident in my ability to work effectively in a team environment and meet project deadlines.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Road Roller Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Road Roller Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Road Roller Engineers play a pivotal role in the construction and maintenance of roads and highways. Their main responsibility is to operate and maintain road rollers.

1. Operate and Maintain Road Rollers

Road Roller Engineers are responsible for operating road rollers to compact and smooth road surfaces.

- Inspect road rollers regularly to ensure they are in good working condition.

- Operate road rollers to compact and smooth road surfaces, ensuring they meet specifications.

- Maintain road rollers, performing regular maintenance and repairs as needed.

2. Prepare Road Surfaces

Before compacting roads, Road Roller Engineers prepare the surface to ensure optimal compaction.

- Inspect road surfaces to identify any areas that need repair or preparation.

- Prepare road surfaces by filling holes, leveling uneven areas, and removing debris.

- Monitor soil conditions and adjust the moisture content for optimal compaction.

3. Monitor Compaction Process

Road Roller Engineers monitor the compaction process to ensure the desired density and smoothness are achieved.

- Conduct tests to measure soil density and smoothness.

- Adjust compaction parameters, such as roller speed and weight, to optimize compaction.

- Record data and provide reports on the compaction process.

4. Work with Other Construction Professionals

Road Roller Engineers collaborate with other professionals to ensure the smooth execution of construction projects.

- Coordinate with construction managers and supervisors to plan and schedule compaction activities.

- Work with surveyors to ensure that roads are built according to design specifications.

- Collaborate with materials engineers to determine the optimal compaction parameters for different soil types.

Interview Tips

Preparing for a Road Roller Engineer interview requires careful research and self-assessment.

1. Research the Company and Position

Before the interview, thoroughly research the company and the specific position.

- Visit the company’s website to learn about their values, projects, and industry standing.

- Use LinkedIn to connect with current and former employees of the company.

- Review the job description carefully to identify the key responsibilities and qualifications required.

2. Practice Your Answers to Common Interview Questions

Anticipate common interview questions and prepare concise and compelling answers.

- Tell me about your experience operating road rollers.

- How do you ensure the quality of your compaction work?

- Describe a challenging project you worked on and how you overcame the obstacles.

- Why are you interested in this position and why do you think you’re a good fit?

3. Highlight Your Technical Skills and Experience

Emphasize your technical skills and experience relevant to the job.

- Quantify your accomplishments with specific numbers and metrics whenever possible.

- Use industry-specific terms and jargon to demonstrate your knowledge of the field.

- Provide examples of projects where you successfully applied your skills.

4. Show Enthusiasm and Interest

During the interview, display genuine interest in the position and the company.

- Be enthusiastic and engaged in the conversation.

- Ask thoughtful questions about the company, the projects, and the role.

- Express your passion for road construction engineering.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Road Roller Engineer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.