Are you gearing up for an interview for a Slab Lifting Engineer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Slab Lifting Engineer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

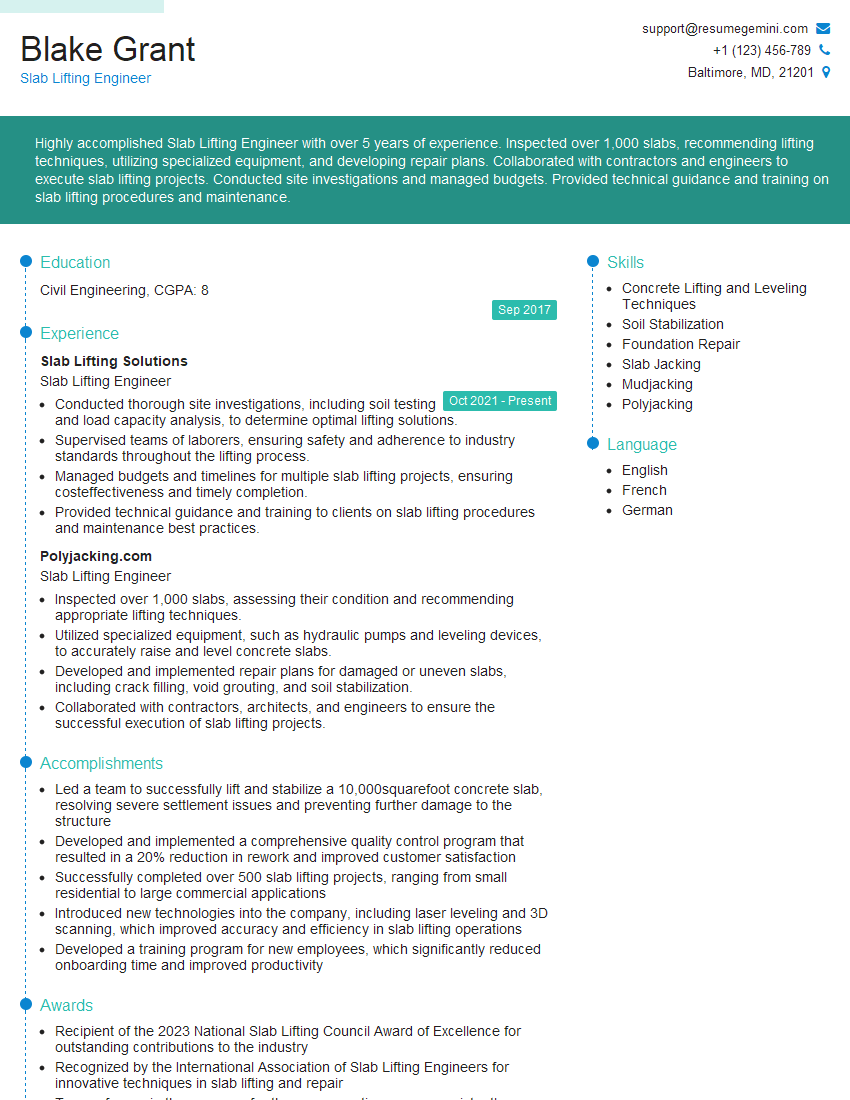

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Slab Lifting Engineer

1. What are the key factors to consider when assessing the condition of a concrete slab prior to lifting?

- Slab thickness and reinforcement

- Presence of cracks, voids, or other defects

- Subgrade conditions and soil bearing capacity

- Environmental factors such as moisture and temperature

- Structural loads and deflections

2. Describe the different methods of slab lifting and their respective advantages and disadvantages.

Foam Injection

- Advantages: Non-invasive, quick and easy, cost-effective

- Disadvantages: Limited lifting height, not suitable for large slabs

Mudjacking

- Advantages: Can lift large slabs, long-lasting results

- Disadvantages: Invasive, requires excavation, can be messy

Slabjacking

- Advantages: High lifting capacity, durable

- Disadvantages: Invasive, requires skilled labor, can be expensive

3. What are the safety precautions that must be observed during slab lifting operations?

- Wear appropriate protective clothing and equipment

- Inspect equipment and materials before use

- Follow manufacturer’s instructions and safety guidelines

- Monitor work area and evacuate personnel in case of emergency

- Have emergency response plan in place

4. How do you determine the appropriate lifting material and injection pressure for a specific slab?

- Consider slab size, thickness, condition, and load

- Refer to manufacturer’s specifications for material compatibility

- Use pressure gauges to monitor injection pressure

- Start with low pressure and gradually increase as needed

- Monitor slab movement and adjust pressure accordingly

5. What are the signs that indicate a slab has been successfully lifted?

- Slab is level and has returned to its original position

- Cracks and voids have been filled

- Subgrade has been stabilized

- Deflections have been reduced

- Slab is structurally sound and stable

6. How do you monitor the progress of a slab lifting project and ensure quality control?

- Use level and measuring instruments to track slab movement

- Inspect lifted areas for any signs of settling or failure

- Document project progress and results

- Follow up with clients to ensure satisfaction

- Maintain records for future reference

7. What are the potential complications that can arise during slab lifting and how do you mitigate them?

- Slab breakage or damage

- Material leaks or spills

- Equipment malfunctions

- Adverse weather conditions

- Have contingency plans in place

- Use experienced and qualified contractors

- Test equipment and materials before use

- Monitor weather forecasts and adjust work schedule as needed

8. What are the environmental considerations associated with slab lifting and how do you address them?

- Use environmentally friendly lifting materials

- Minimize waste and dispose of materials properly

- Protect surrounding areas from contamination

- Comply with environmental regulations

- Obtain necessary permits and approvals

9. How do you handle customer inquiries and complaints related to slab lifting services?

- Listen attentively to concerns and queries

- Provide clear and accurate information

- Resolve issues promptly and professionally

- Document interactions and follow up as needed

- Maintain positive customer relationships

10. What are the industry standards and best practices for slab lifting?

- American Concrete Institute (ACI) guidelines

- International Association of Concrete Repair and Restoration (IACRR) standards

- American Society of Civil Engineers (ASCE) specifications

- National Concrete Pavement Technology Center (NCPTC) recommendations

- Manufacturer’s instructions and technical bulletins

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Slab Lifting Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Slab Lifting Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Slab Lifting Engineers are responsible for planning, executing, and overseeing slab lifting projects. They work closely with clients to assess the condition of concrete slabs, develop lifting plans, and ensure the successful completion of each project.

1. Site Assessment

Conduct thorough site assessments to evaluate the condition of concrete slabs, identify areas requiring lifting, and determine the appropriate lifting method.

- Inspect slabs for cracks, settlement, and other damage.

- Use ground-penetrating radar or other non-destructive testing methods to assess subsurface conditions.

- Determine the cause of slab settlement and recommend solutions to prevent future problems.

2. Project Planning

Develop detailed project plans that outline the lifting method, equipment requirements, materials, and schedule.

- Select the appropriate lifting method based on the size, weight, and condition of the slab.

- Determine the number and placement of lifting points.

- Calculate the amount of lifting material required.

- Create a project schedule outlining the sequence of operations and estimated completion time.

3. Equipment Operation

Operate specialized equipment to lift and level concrete slabs.

- Use hydraulic pumps and jacks to lift slabs.

- Monitor gauges and sensors to ensure safe and precise lifting.

- Fill voids under slabs with grout or other lifting materials.

4. Quality Control

Ensure the quality of lifted slabs meets industry standards.

- Inspect slabs after lifting to verify levelness and stability.

- Conduct follow-up inspections to ensure long-term performance.

Interview Tips

Preparing thoroughly for an interview as a Slab Lifting Engineer can significantly increase your chances of success. Consider the following tips to enhance your preparation:

1. Research the Company and Position

Gain insights into the company’s values, services, and clientele. Understand the specific responsibilities and expectations of the Slab Lifting Engineer role.

- Visit the company’s website and review their services and project portfolio.

- Connect with current or former employees on LinkedIn to gather firsthand information.

- Thoroughly read the job description and identify the key skills and qualifications required.

2. Quantify Your Experience

When describing your past experiences, focus on providing specific and quantifiable results. Use metrics and data to demonstrate your accomplishments and the impact of your work.

- For example, instead of saying “I lifted numerous concrete slabs,” say “I lifted over 250 concrete slabs, resulting in an average settlement reduction of 2 inches.”

3. Showcase Your Technical Expertise

Slab Lifting Engineering requires a strong understanding of structural engineering, materials, and lifting techniques. Highlight your knowledge and experience in these areas.

- Discuss your experience with different lifting methods, such as mudjacking, pressure grouting, and void filling.

- Explain your understanding of concrete properties, slab behavior, and soil mechanics.

- Demonstrate your proficiency in using surveying equipment, monitoring tools, and project management software.

4. Emphasize Safety and Quality

Safety and quality are paramount in Slab Lifting Engineering. Convince the interviewer that you prioritize these aspects in your work.

- Discuss your adherence to industry safety protocols and regulations.

- Highlight your commitment to delivering high-quality results and ensuring the longevity of lifted slabs.

5. Practice Your Answers

Prepare for common interview questions by practicing your answers. This will help you deliver clear and concise responses during the actual interview.

- Review examples of technical questions related to slab lifting, such as “Explain the factors that affect slab settlement.”.

- Practice situational questions, such as “Describe a challenging slab lifting project you encountered and how you overcame the obstacles.”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Slab Lifting Engineer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!