Feeling lost in a sea of interview questions? Landed that dream interview for Sand Technologist but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Sand Technologist interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

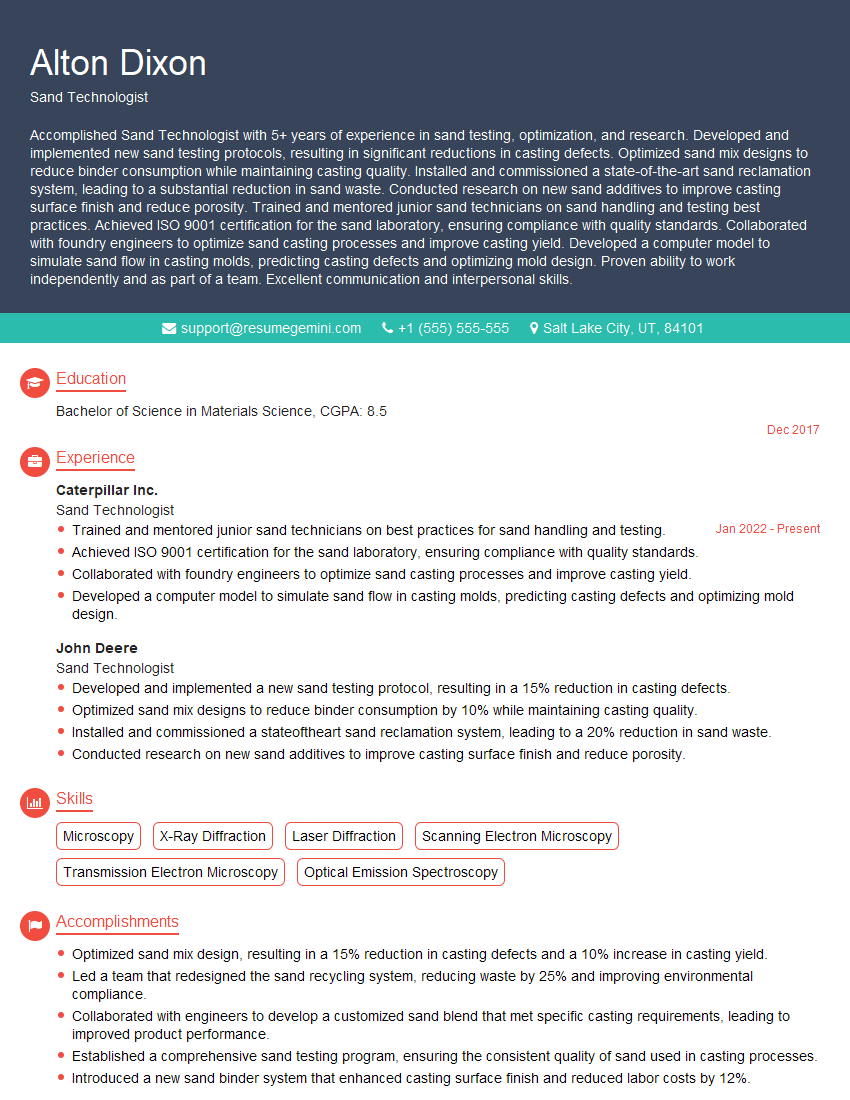

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sand Technologist

1. What is the role of sand in metal casting?

Sand plays a crucial role in metal casting by serving several essential functions:

- Mold Formation: Sand is the primary material used to create the mold cavity that shapes the molten metal. It offers the necessary strength and porosity to retain the molten metal and withstand the casting process.

- Heat Resistance: Sand possesses high thermal resistance, enabling it to withstand the extreme temperatures generated during casting. This property prevents premature cooling of the molten metal and ensures proper solidification.

- Gas Permeability: Sand is permeable, allowing gases generated during the casting process to escape. This prevents the formation of defects and ensures the integrity of the cast product.

2. Explain the different types of sand used in foundries.

Green Sand

- Most commonly used in foundries

- Contains clay as a binder, along with water

- Provides good moldability and strength

Chemical Bonded Sand

- Uses chemical binders instead of clay

- Offers higher strength and dimensional accuracy

- Can be recycled multiple times

No-Bake Sand

- Utilizes a liquid resin as a binder

- Cures at room temperature without heat

- Provides excellent surface finish and dimensional accuracy

3. Describe the process of sand preparation for casting.

- Sand Mixing: Sand is mixed with binders, moisture, and other additives to achieve the desired properties.

- Aerating: Sand is aerated to remove lumps and ensure proper flowability.

- Testing: Sand properties, such as strength, permeability, and moisture content, are tested to meet specifications.

- Mulling: Sand is mixed thoroughly to distribute binders and additives evenly.

4. What are the critical properties of sand in metal casting?

- Grain Size and Shape: Affects mold properties like permeability, strength, and surface finish.

- Clay Content: Determines the mold’s strength and green compressive strength.

- Permeability: Allows gases to escape from the mold during casting.

- Refractoriness: Resists high temperatures without melting or deteriorating.

- Moisture Content: Impacts mold strength and workability.

5. Discuss the importance of sand control in foundries.

Sand control is crucial for several reasons:

- Quality Control: Maintains the consistent quality of sand properties, ensuring the production of high-quality castings.

- Process Optimization: Optimizes casting processes by controlling sand properties and preventing defects.

- Environmental Compliance: Minimizes waste and environmental impact by recycling and reusing sand.

- Cost Reduction: Efficient sand control reduces sand consumption and waste, resulting in cost savings.

6. Explain the methods used for sand testing in foundries.

- Compressive Strength Test: Measures the mold’s ability to resist compression.

- Permeability Test: Determines the mold’s ability to allow gases to escape.

- Moisture Content Test: Determines the amount of water in the sand.

- Grain Size Analysis: Determines the distribution of sand grain sizes.

- Refractoriness Test: Assesses the mold’s ability to withstand high temperatures.

7. Describe the different types of casting defects related to sand.

- Scabs: Defects caused by gas entrapment in the mold.

- Inclusions: Defects caused by foreign materials in the mold.

- Washes: Defects caused by erosion of the mold surface.

- Cold Shots: Defects caused by premature solidification of the molten metal.

- Rat Tails: Defects caused by metal penetration into the mold.

8. How do you troubleshoot sand-related defects in metal castings?

- Identify the defect: Analyze the defect to determine its cause.

- Check sand properties: Confirm that sand properties meet specifications.

- Inspect the molding process: Ensure proper sand preparation and molding techniques.

- Review casting parameters: Optimize casting temperature, cooling rate, and other parameters.

- Implement corrective measures: Adjust sand properties, molding process, or casting parameters as needed to eliminate defects.

9. What are the advancements in sand technology for metal casting?

- Synthetic Sands: Engineered sands with controlled properties for improved casting quality.

- Additive Manufacturing: 3D printing of sand molds for complex geometries.

- Mold Coating Technologies: Advanced coatings to enhance mold surface properties and reduce defects.

- Sand Reclamation Systems: Automated systems to recycle and reuse sand, reducing waste.

10. How can sand technologists contribute to the sustainability of foundry operations?

- Developing eco-friendly sand binders: Reducing environmental impact through the use of biodegradable and recyclable binders.

- Optimizing sand reclamation processes: Minimizing waste and reducing landfill disposal.

- Promoting sustainable sand sourcing: Ensuring responsible sand extraction and minimizing depletion of natural resources.

- Educating foundry personnel: Enhancing knowledge of sand technology and promoting best practices for sustainability.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sand Technologist.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sand Technologist‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Sand Technologists are responsible for developing and maintaining the quality of foundry sand for casting applications. Their key job responsibilities include:

1. Sand Testing and Analysis

Conducting various tests on foundry sand, such as grain size analysis, moisture content, permeability, and strength, to assess its properties and suitability for specific casting processes.

2. Sand Mixing and Blending

Developing and optimizing sand mixtures by combining different types of sand, binders, and additives to achieve desired properties for different casting applications.

3. Sand Reclamation and Recycling

Implementing and managing sand reclamation and recycling processes to reduce waste and improve environmental sustainability in the foundry. This involves removing contaminants, such as burnt sand and metal particles, from used sand.

4. Quality Control and Troubleshooting

Establishing and maintaining quality control measures to ensure the consistency and performance of foundry sand. Investigating and troubleshooting any problems related to sand quality or casting defects.

5. Experimentation and Process Development

Conducting research and experimentation to develop new sand technologies, improve existing processes, and optimize casting operations. Collaborating with other departments, such as design and engineering, to ensure that sand specifications meet casting requirements.

Interview Tips

To ace your interview for a Sand Technologist position, consider the following tips:

1. Research the Company and Industry

Familiarize yourself with the company’s foundry operations, casting processes, and specific sand requirements. Research the latest industry trends and best practices related to sand technology.

2. Highlight Your Technical Skills

Emphasize your knowledge of sand testing techniques, sand mixing and blending principles, and sand reclamation processes. Quantify your experience with specific equipment and software used in sand technology.

3. Showcase Your Problem-Solving Abilities

Provide examples of how you have successfully resolved sand-related issues in previous roles. Discuss your approach to troubleshooting casting defects and optimizing sand performance.

4. Demonstrate Your Communication and Teamwork Skills

Explain how you effectively collaborate with colleagues in design, engineering, and production departments to ensure the proper implementation of sand technologies. Highlight your ability to communicate technical information clearly and persuasively.

5. Prepare for Specific Questions

Anticipate questions related to your experience with different types of foundry sand, sand additives, and sand reclamation systems. Practice answering questions about your understanding of sand properties and how you optimize them for various casting applications.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Sand Technologist, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Sand Technologist positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.