Feeling lost in a sea of interview questions? Landed that dream interview for Drywall Taper but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Drywall Taper interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

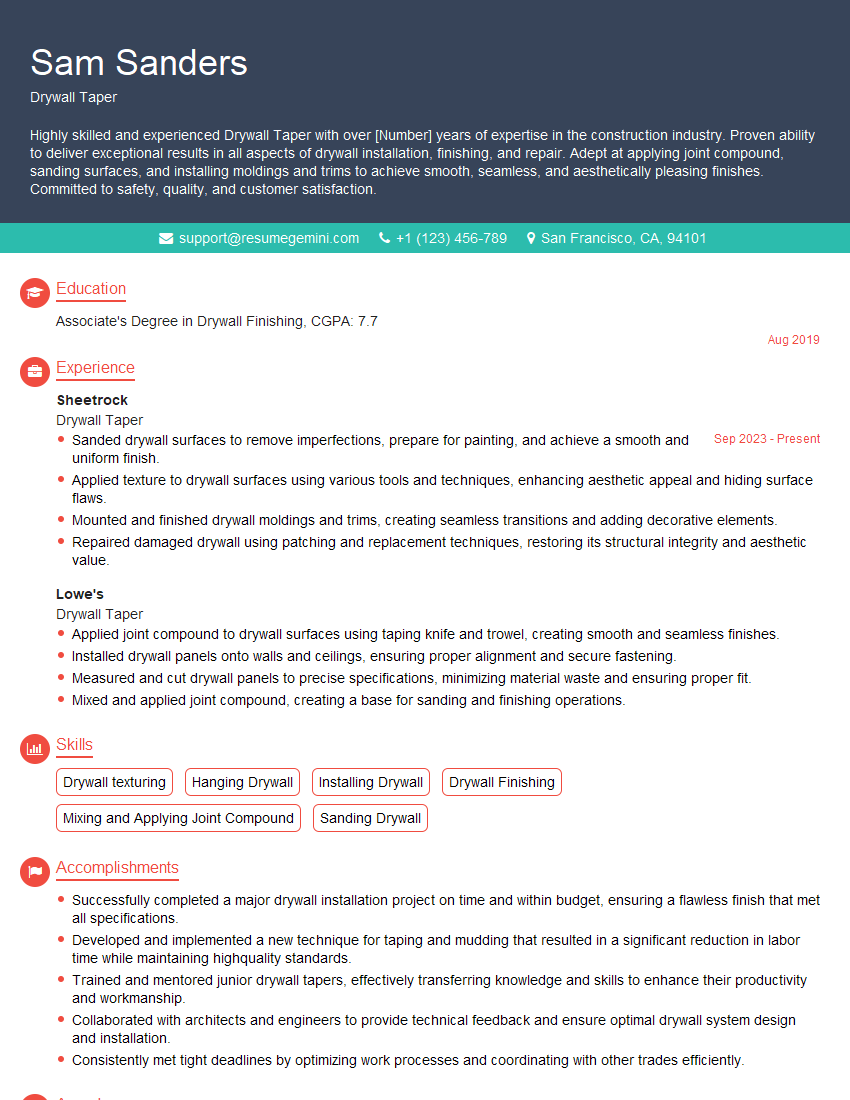

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Drywall Taper

1. What are the different types of drywall joints and how do you finish each type?

- Butt joints: Butt joints are created when two pieces of drywall are placed side-by-side without any overlap. To finish a butt joint, apply a thin layer of joint compound to the joint, then embed drywall tape into the compound. Once the compound has dried, apply a second coat of compound and smooth it out.

- Corner joints: Corner joints are created when two pieces of drywall meet at a 90-degree angle. To finish a corner joint, apply a thin layer of joint compound to the joint, then embed drywall tape into the compound. Once the compound has dried, apply a second coat of compound and smooth it out. Use a corner trowel to create a clean, sharp corner.

- Inside corners: Inside corners are created when two pieces of drywall meet at an angle less than 90 degrees. To finish an inside corner, apply a thin layer of joint compound to the joint, then embed drywall tape into the compound. Once the compound has dried, apply a second coat of compound and smooth it out. Use an inside corner tool to create a clean, sharp corner.

- Outside corners: Outside corners are created when two pieces of drywall meet at an angle greater than 90 degrees. To finish an outside corner, apply a thin layer of joint compound to the joint, then embed drywall tape into the compound. Once the compound has dried, apply a second coat of compound and smooth it out. Use an outside corner tool to create a clean, sharp corner.

2. What are the different types of drywall textures and how do you apply each type?

Knockdown texture

- Knockdown texture is a popular drywall texture that is created by spraying a thin layer of joint compound onto the drywall, then knocking it down with a trowel or sponge.

- To apply knockdown texture, first apply a thin layer of joint compound to the drywall. Then, use a trowel or sponge to knock down the compound, creating a rough, textured surface.

Popcorn texture

- Popcorn texture is a textured drywall finish that is created by spraying a mixture of joint compound and popcorn kernels onto the drywall.

- To apply popcorn texture, first mix together a batch of joint compound and popcorn kernels. Then, use a hopper gun to spray the mixture onto the drywall. The popcorn kernels will stick to the joint compound and create a textured surface.

Orange peel texture

- Orange peel texture is a drywall texture that is created by spraying a thin layer of joint compound onto the drywall, then rolling it out with a paint roller.

- To apply orange peel texture, first apply a thin layer of joint compound to the drywall. Then, use a paint roller to roll out the compound, creating a textured surface.

3. What are the different tools and materials that you use as a drywall taper?

- Drywall knife: A drywall knife is a tool that is used to apply and smooth joint compound.

- Drywall tape: Drywall tape is a thin, self-adhesive tape that is used to reinforce drywall joints.

- Joint compound: Joint compound is a powder that is mixed with water to create a paste that is used to fill and smooth drywall joints.

- Sander: A sander is a tool that is used to smooth drywall surfaces.

- Drop cloths: Drop cloths are used to protect floors and furniture from drywall dust.

4. What are the steps involved in taping and floating a drywall joint?

- Apply a thin layer of joint compound to the joint.

- Embed drywall tape into the joint compound.

- Apply a second coat of joint compound and smooth it out.

- Sand the joint smooth.

5. What are the common problems that you encounter as a drywall taper and how do you solve them?

- Bubbles: Bubbles can occur when there is air trapped between the drywall and the joint compound. To solve this problem, use a drywall knife to pop the bubbles and then smooth out the joint compound.

- Cracks: Cracks can occur when the joint compound dries too quickly or if it is not applied properly. To solve this problem, widen the crack with a drywall knife and then fill it with joint compound. Once the joint compound has dried, sand it smooth.

- Nail pops: Nail pops occur when the nails that are used to attach the drywall to the studs pop through the drywall. To solve this problem, use a drywall knife to countersink the nail and then fill the hole with joint compound. Once the joint compound has dried, sand it smooth.

6. What are the safety precautions that you take when working as a drywall taper?

- Wear a dust mask to protect yourself from drywall dust.

- Wear safety glasses to protect your eyes from flying debris.

- Wear gloves to protect your hands from joint compound and other chemicals.

- Use a ladder safely when working on high walls.

- Be aware of your surroundings and avoid tripping hazards.

7. What is your experience with working with different types of drywall, such as fire-rated drywall and moisture-resistant drywall?

Fire-rated drywall

- Fire-rated drywall is a type of drywall that is designed to resist fire for a certain period of time.

- I have experience working with fire-rated drywall on several projects and I am familiar with the special requirements for installing and finishing this type of drywall.

Moisture-resistant drywall

- Moisture-resistant drywall is a type of drywall that is designed to resist moisture and mold.

- I have experience working with moisture-resistant drywall on several projects and I am familiar with the special requirements for installing and finishing this type of drywall.

8. What are your strengths and weaknesses as a drywall taper?

Strengths

- I am a highly skilled and experienced drywall taper with over 10 years of experience.

- I am proficient in all aspects of drywall finishing, including taping, floating, and texturing.

- I am a hard worker and I am always willing to go the extra mile to get the job done right.

- I am a team player and I am always willing to help out my fellow workers.

Weaknesses

- I am not always the most organized person, but I am always able to get the job done on time and to a high standard.

- I am not always the most patient person, but I am always able to control my temper and work well with others.

9. What are your career goals?

- My career goal is to become a master drywall taper and to eventually start my own drywall business.

- I am confident that I have the skills and experience necessary to achieve my goals.

- I am eager to learn new skills and techniques, and I am always looking for ways to improve my work.

10. Do you have any questions for me?

I would like to know more about the company culture and the specific requirements of this position.

I would also like to know what the company’s expectations are for a drywall taper and what opportunities there are for advancement.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Drywall Taper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Drywall Taper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Drywall tapers are responsible for applying a smooth, even finish to drywall walls and ceilings. They use a variety of tools and materials to complete their work, including taping knives, joint compound, and sandpaper. The key job responsibilities of a drywall taper include:

1. Applying joint compound to drywall seams

Drywall tapers use taping knives to apply joint compound to the seams between drywall panels. This compound fills in any gaps or imperfections in the drywall, creating a smooth surface.

2. Smoothing and finishing joint compound

Once the joint compound has been applied, drywall tapers use sanding sponges or screens to smooth and finish the surface. They work carefully to remove any bumps or ridges, leaving behind a smooth, even finish.

3. Applying texture to drywall

In some cases, drywall tapers may also be responsible for applying texture to drywall. This can be done using a variety of tools and techniques, such as spraying, rolling, or troweling. Texture can help to hide imperfections in the drywall and give it a more finished look.

4. Repairing damaged drywall

Drywall tapers are also responsible for repairing damaged drywall. This may involve patching holes, replacing damaged panels, or resurfacing damaged areas.

Interview Tips

Preparing for a drywall taper interview can help you make a good impression and increase your chances of getting the job. Here are a few tips to help you prepare:

1. Research the company and the position

Before your interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and goals. It will also help you tailor your answers to the specific requirements of the position.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. Take some time to practice your answers to these questions so that you can deliver them confidently and concisely.

3. Be prepared to talk about your experience

Be prepared to talk about your experience as a drywall taper. This includes your skills, knowledge, and accomplishments. Be specific and provide examples whenever possible.

4. Be prepared to ask questions

Asking questions at the end of the interview is a great way to show that you are interested in the position and the company. Prepare a few questions that you can ask the interviewer, such as “What are the biggest challenges facing the company right now?” or “What are the opportunities for advancement within the company?”.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Drywall Taper interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.