Are you gearing up for a career in Electrolysis and Corrosion Control Engineer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Electrolysis and Corrosion Control Engineer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

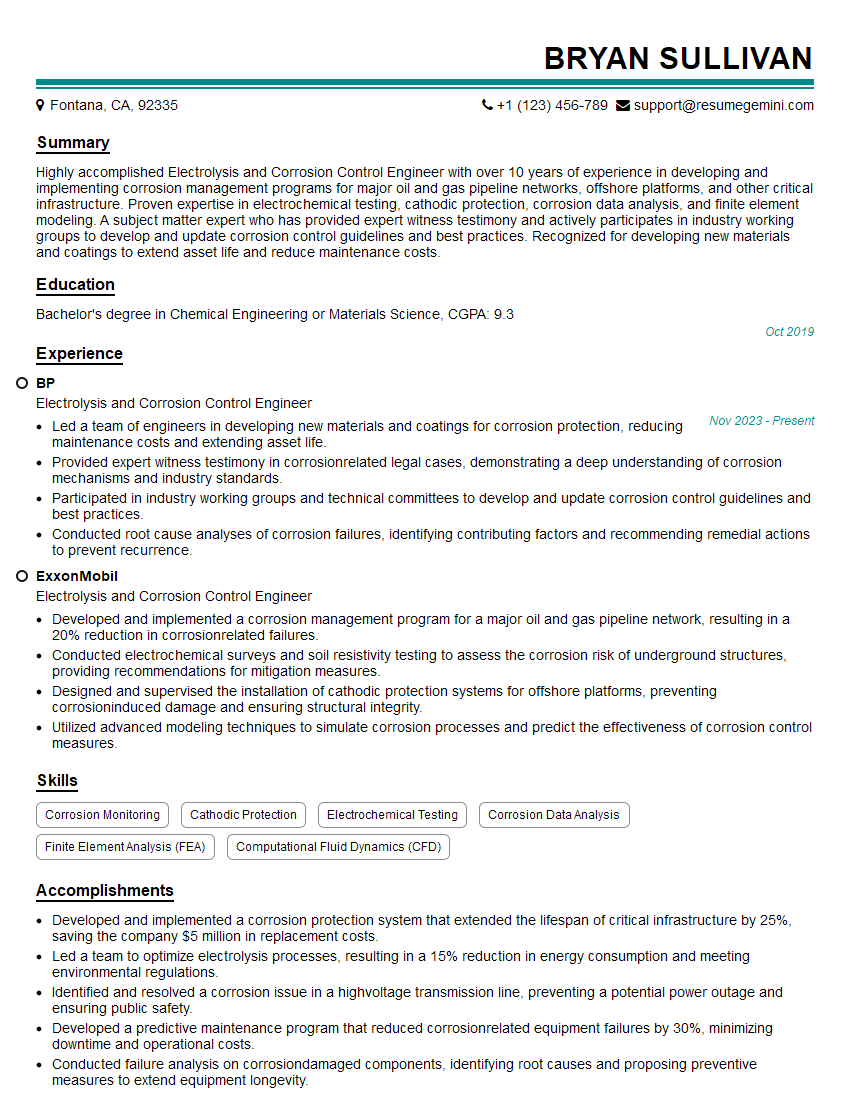

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Electrolysis and Corrosion Control Engineer

1. Explain the Faraday’s law of electrolysis in detail

- Faraday’s law of electrolysis relates the mass of a substance deposited or evolved at an electrode to the amount of electrical charge passed through the electrode.

- The mass of the substance deposited or evolved is directly proportional to the amount of charge passed through the electrode.

- The constant of proportionality is called the electrochemical equivalent.

2. Describe the different types of corrosion cells and how they can be prevented

Galvanic corrosion

- Galvanic corrosion occurs when two dissimilar metals are in contact with each other in the presence of an electrolyte.

- The more active metal will corrode (anode), while the less active metal will be protected (cathode).

- Galvanic corrosion can be prevented by using sacrificial anodes, cathodic protection, or by using a barrier coating.

Pitting corrosion

- Pitting corrosion is a localized form of corrosion that occurs when a small area of metal is attacked by an electrolyte.

- Pitting corrosion can be prevented by using a protective coating, by using an inhibitor, or by increasing the pH of the electrolyte.

Stress corrosion cracking

- Stress corrosion cracking is a type of corrosion that occurs when a metal is subjected to a tensile stress in the presence of an electrolyte.

- Stress corrosion cracking can be prevented by using a stress-relieving heat treatment, by using an inhibitor, or by using a protective coating.

3. What are the different methods of cathodic protection and how do they work?

- Sacrificial anodes

- Sacrificial anodes are made of a more active metal than the metal to be protected.

- The sacrificial anode corrodes instead of the protected metal.

- Impressed current cathodic protection

- Impressed current cathodic protection uses an external power source to apply a cathodic current to the protected metal.

- The cathodic current prevents the protected metal from corroding.

4. What are the different types of corrosion inhibitors and how do they work?

- Anodic inhibitors

- Anodic inhibitors work by forming a protective film on the surface of the metal.

- This film prevents the metal from coming into contact with the corrosive environment.

- Cathodic inhibitors

- Cathodic inhibitors work by reducing the rate of the cathodic reaction.

- This reduces the amount of corrosion that occurs.

- Mixed inhibitors

- Mixed inhibitors work by both anodic and cathodic mechanisms.

- They are typically more effective than either anodic or cathodic inhibitors alone.

5. What are the different types of corrosion monitoring techniques and how do they work?

- Visual inspection

- Visual inspection is the most basic corrosion monitoring technique.

- It involves looking for signs of corrosion, such as rust, pitting, or cracking.

- Electrochemical techniques

- Electrochemical techniques measure the electrical properties of the metal surface.

- These techniques can be used to detect corrosion even before it is visible to the naked eye.

- Non-destructive testing

- Non-destructive testing techniques use sound waves, X-rays, or other methods to inspect the metal surface without damaging it.

- These techniques can be used to detect hidden corrosion.

6. What are the different factors that affect the rate of corrosion?

- The type of metal

- The environment

- The temperature

- The presence of stress

- The presence of inhibitors

7. What are the different methods of corrosion control?

- Protective coatings

- Cathodic protection

- Corrosion inhibitors

- Proper design and maintenance

8. What are the different types of electrochemical cells and how do they work?

- Galvanic cells

- Galvanic cells are made up of two dissimilar metals that are in contact with each other.

- The more active metal will corrode (anode), while the less active metal will be protected (cathode).

- Electrolytic cells

- Electrolytic cells are made up of two electrodes that are immersed in an electrolyte.

- An external power source is used to apply a voltage to the electrodes.

- The voltage causes the metal at the anode to corrode, while the metal at the cathode is protected.

9. What are the different types of electrochemical reactions and how do they occur?

- Oxidation

- Oxidation is a reaction in which a metal loses electrons.

- Oxidation occurs at the anode of an electrochemical cell.

- Reduction

- Reduction is a reaction in which a metal gains electrons.

- Reduction occurs at the cathode of an electrochemical cell.

10. What are the different applications of electrolysis and corrosion control?

- Electrolysis is used in a variety of applications, including electroplating, electrorefining, and electrowinning.

- Corrosion control is used to protect metal structures from corrosion.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Electrolysis and Corrosion Control Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Electrolysis and Corrosion Control Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Electrolysis and Corrosion Control Engineers are tasked with designing and implementing corrosion control measures to protect buildings, bridges, and other infrastructures from the effects of electrolysis and corrosion. The key tasks and responsibilities include:

1. Inspection and Assessment

Inspecting and assessing structures to identify areas of corrosion or potential corrosion risk.

Evaluating the severity of corrosion damage and recommending appropriate repair or replacement strategies.

Conducting electrochemical testing such as linear polarization resistance (LPR) and cathodic protection (CP) surveys to determine the extent of corrosion and the effectiveness of corrosion control measures.

2. Design and Implementation

Designing and implementing corrosion control systems, including cathodic protection systems, coatings, and inhibitors.

Selecting appropriate materials and construction methods to prevent or minimize corrosion.

Ensuring compliance with industry standards and regulations related to corrosion control.

3. Monitoring and Maintenance

Monitoring and maintaining corrosion control systems to ensure their effectiveness.

Conducting regular inspections and testing to identify any signs of corrosion or system failure.

Performing repairs or replacements as necessary to maintain the integrity of structures.

4. Research and Development

Staying updated on the latest developments in corrosion control technologies and practices.

Conducting research and development to improve existing corrosion control methods or develop new ones.

Participating in industry conferences and workshops to share knowledge and learn from others.

Interview Tips

Preparing for an interview for an Electrolysis and Corrosion Control Engineer position requires a combination of technical knowledge and soft skills. Here are some tips:

1. Technical Expertise

Review the key job responsibilities and ensure you have a strong understanding of the principles of electrolysis and corrosion control.

Brush up on relevant industry standards and regulations.

Be prepared to discuss your experience in conducting corrosion surveys, designing corrosion control systems, and monitoring their effectiveness.

2. Communication Skills

Practice communicating technical information clearly and effectively.

Be prepared to explain complex concepts to both technical and non-technical audiences.

Highlight your ability to write technical reports and presentations.

3. Problem-Solving Ability

Showcase your problem-solving skills by providing examples of how you have identified and resolved corrosion issues.

Explain your approach to decision-making and how you prioritize different factors when recommending solutions.

Discuss your experience in working with contractors and other stakeholders to implement corrosion control measures.

4. Industry Awareness

Research the industry in which the organization operates and understand the specific challenges and regulations that apply.

Be aware of the latest trends and developments in corrosion control technology.

Demonstrate your commitment to continuous learning and professional development.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Electrolysis and Corrosion Control Engineer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.