Feeling lost in a sea of interview questions? Landed that dream interview for Insulation Blower but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Insulation Blower interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

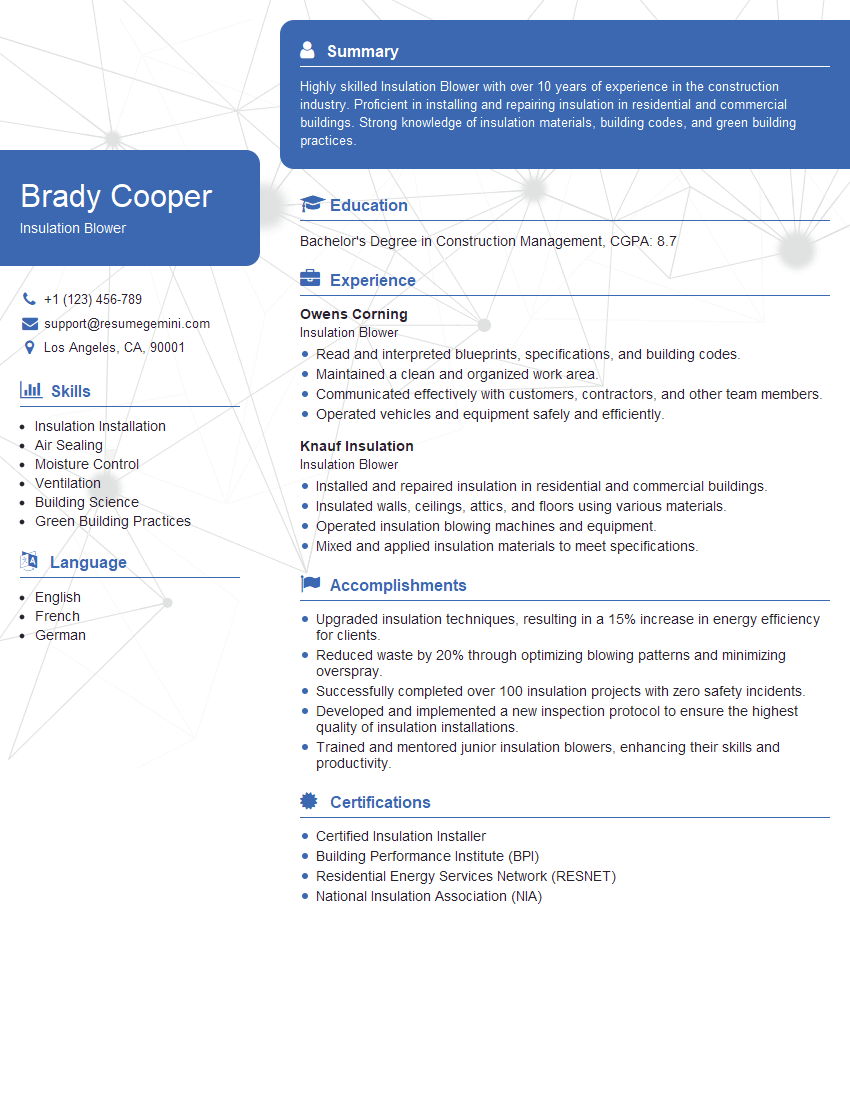

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Insulation Blower

1. Describe the steps involved in preparing a surface for insulation blowing?

- Inspect the surface for any damage or obstructions.

- Remove any debris or obstacles from the surface.

- Clean the surface to remove any dirt or dust.

- Apply a primer or sealant to the surface to improve adhesion.

2. Explain the different types of insulation materials used in insulation blowing and their applications?

Fiberglass

- Commonly used in residential and commercial buildings.

- Effective at reducing heat loss and noise.

Cellulose

- Made from recycled paper and other materials.

- Fire-resistant and environmentally friendly.

Polystyrene

- Lightweight and moisture-resistant.

- Often used in exterior walls and foundations.

3. How do you calculate the amount of insulation material required for a given space?

- Measure the area of the surface to be insulated.

- Determine the desired insulation thickness.

- Multiply the area by the thickness to calculate the volume of insulation needed.

- Convert the volume to the appropriate units (e.g., cubic feet, bags).

4. What safety precautions should be taken when operating an insulation blower?

- Wear proper protective gear (e.g., respirator, gloves).

- Ventilate the work area properly.

- Avoid contact with electrical wires and other hazards.

- Follow the manufacturer’s operating instructions carefully.

5. Describe the different techniques used to apply insulation using a blower?

- Dry blowing: Insulation is blown directly onto the surface.

- Wet blowing: Insulation is mixed with water or adhesive before being blown.

- Dense packing: Insulation is densely packed into cavities or tight spaces.

- Spray-on insulation: Insulation is applied using a spray gun.

6. How do you inspect the quality of insulation after it has been blown?

- Check the thickness and coverage of the insulation.

- Look for any gaps or voids in the insulation.

- Test the insulation’s thermal resistance using a heat gun.

7. What are the common challenges faced when installing insulation using a blower?

- Uneven coverage due to wind or drafts.

- Insulation settling over time.

- Difficulty reaching hard-to-access areas.

- Moisture accumulation.

8. How do you troubleshoot common problems that may arise during insulation blowing?

- Clogged hose: Clear the hose of any obstructions.

- Insufficient air pressure: Check the air compressor and adjust the pressure.

- Leaks in the system: Inspect the hoses and fittings for leaks.

- Insulation bridging: Increase the air pressure or use a denser insulation material.

9. Explain how to maintain an insulation blower and extend its lifespan?

- Clean the blower regularly to remove dust and debris.

- Inspect the hoses and fittings for damage and replace them if necessary.

- Lubricate the blower according to the manufacturer’s instructions.

- Store the blower in a dry and sheltered location.

10. Stay up-to-date with the latest technologies and advancements in insulation blowing techniques?

- Attend industry conferences and workshops.

- Read trade publications and research articles.

- Consult with experts in the field.

- Explore new materials and techniques.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Insulation Blower.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Insulation Blower‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Insulation Blowers are responsible for installing insulation in various types of buildings, including residential homes, commercial buildings, and industrial facilities. Their primary task is to blow loose-fill insulation material into attics, walls, and other areas where insulation is needed.

1. Insulation Installation

Insulation Blowers use specialized equipment to blow loose-fill insulation material, such as fiberglass, cellulose, and rock wool, into designated areas.

- Operate insulation blowing machines to install insulation in attics, walls, and other areas.

- Ensure proper insulation coverage and thickness as per building codes and project specifications.

2. Insulation Material Handling

Insulation Blowers handle and transport insulation materials from storage to installation sites.

- Unload and transfer insulation materials from delivery trucks to job sites.

- Prepare insulation materials for installation by fluffing and blending different types of insulation.

3. Equipment Maintenance

Insulation Blowers maintain and troubleshoot insulation blowing equipment to ensure optimal performance.

- Inspect and clean insulation blowing machines, hoses, and nozzles regularly.

- Perform minor repairs and maintenance on equipment to minimize downtime and ensure efficient operation.

4. Safety Compliance

Insulation Blowers adhere to safety protocols and regulations while working with insulation materials and equipment.

- Wear appropriate personal protective equipment (PPE) such as respirators, gloves, and protective clothing.

- Follow established safety procedures for handling and installing insulation materials.

Interview Tips

Preparing for an interview as an Insulation Blower can enhance your chances of making a positive impression on potential employers. Here are some tips to help you ace the interview:

1. Research the Company and Position

Research the company you are applying to and the specific Insulation Blower position. This will help you understand the company’s culture, values, and the role’s responsibilities and expectations.

- Visit the company’s website to learn about their mission, services, and recent projects.

- Review job descriptions and industry articles to gain insights into the role’s requirements and industry best practices.

2. Highlight Your Skills and Experience

Emphasize your relevant skills and experience in insulation installation, equipment handling, and safety compliance. Quantify your accomplishments whenever possible to demonstrate your impact and value.

- Describe your experience in operating insulation blowing machines and handling different types of insulation materials.

- Provide examples of projects where you ensured proper insulation coverage and met building codes.

3. Prepare for Common Interview Questions

Anticipate common interview questions and prepare thoughtful responses that showcase your qualifications and enthusiasm for the role. Research industry-specific questions to demonstrate your knowledge and understanding of the field.

- Explain your understanding of different types of insulation materials and their applications.

- Describe your experience in maintaining and troubleshooting insulation blowing equipment.

4. Ask Informed Questions

Asking well-informed questions during the interview shows your interest and engagement. Prepare questions related to the company’s sustainability initiatives, industry trends, or specific challenges within the role.

- Inquire about the company’s commitment to energy efficiency and green building practices.

- Ask about opportunities for professional development and advancement within the company.

5. Be Professional and Enthusiastic

Dress professionally and arrive on time for your interview. Maintain a positive and enthusiastic attitude throughout the interview. Demonstrate your passion for insulation installation and your desire to contribute to the company’s success.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Insulation Blower interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.