Are you gearing up for a career in Rock Wool Applicator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Rock Wool Applicator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

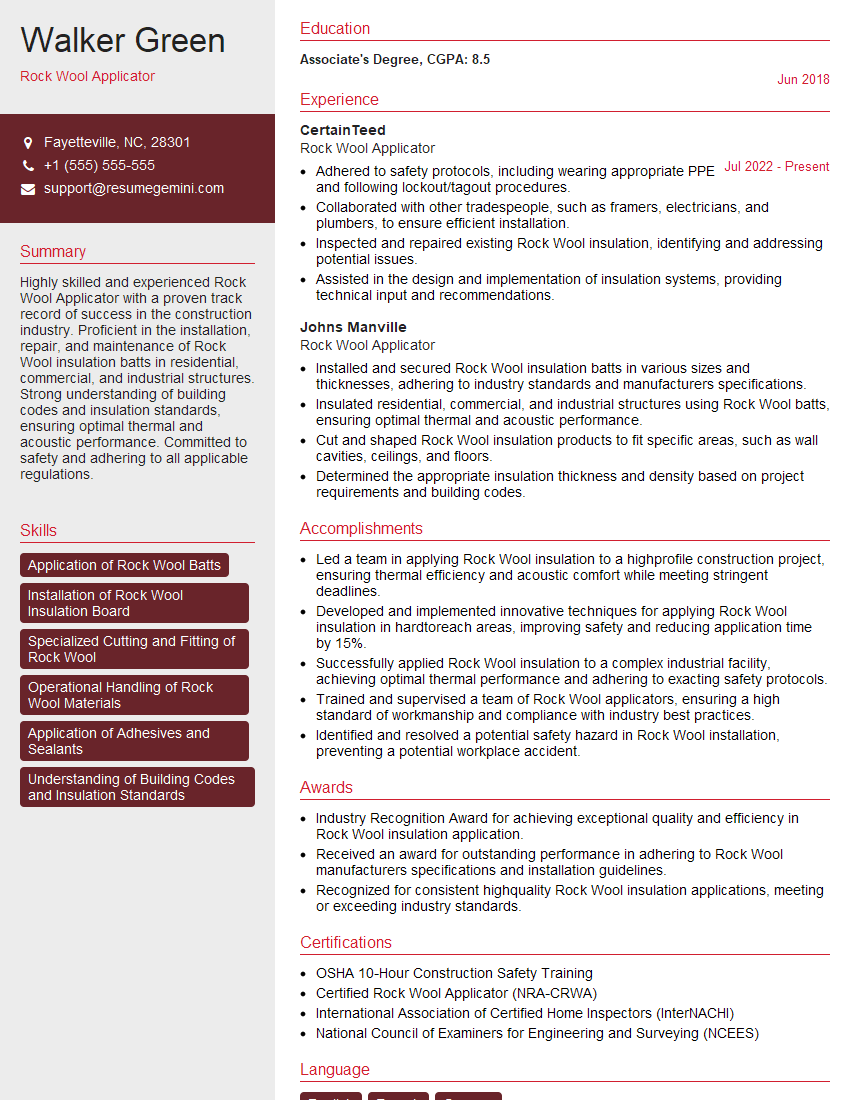

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rock Wool Applicator

1. Can you describe the different types of rock wool used in construction and their applications?

In construction, rock wool is widely used for various purposes. Let me outline the different types of rock wool and their typical applications:

- Loose-fill rock wool: This type of rock wool is typically used as insulation in attics, walls, and other cavities. It’s known for its excellent thermal and acoustic insulation properties.

- Batt rock wool: Batt rock wool comes in pre-cut sheets or rolls, making it convenient for installing in stud walls, ceilings, and floors. It offers efficient thermal insulation and sound absorption.

- Rigid rock wool: Rigid rock wool is manufactured in board form and is commonly used for exterior insulation systems, such as external wall insulation and cladding systems. It provides excellent thermal performance and helps in reducing heat loss.

2. How do you ensure proper ventilation when installing rock wool insulation?

Maintaining Airflow

- Plan for proper airflow and ventilation channels within the insulation system to prevent moisture buildup.

- Ensure there are no obstructions, such as fiberglass, that can hinder airflow.

Vapor Barriers and Air Gaps

- Install vapor barriers to prevent warm, moist air from reaching cold surfaces and condensing within the insulation, leading to moisture problems.

- Create air gaps between the insulation and the vapor barrier, allowing for air circulation and preventing condensation.

3. What safety precautions should be taken when working with rock wool?

- Wear appropriate personal protective equipment (PPE): This includes gloves, safety glasses, a mask, and coveralls to minimize exposure to dust and fibers.

- Minimize dust exposure: Keep work areas well-ventilated to reduce airborne fibers. Use dust masks and respirators when necessary.

- Avoid skin contact: Rock wool fibers can cause skin irritation, so wear protective clothing that covers exposed skin.

- Clean up properly: Use vacuum cleaners equipped with HEPA filters for dust removal. Dampen the area before sweeping or vacuuming to minimize dust dispersion.

- Dispose of waste properly: Rock wool waste should be disposed of according to local regulations, usually in designated landfills.

4. How do you determine the appropriate thickness of rock wool insulation for a specific application?

Several factors influence the appropriate thickness of rock wool insulation for a specific application:

- Climate and location: Colder climates generally require thicker insulation to maintain thermal comfort and energy efficiency.

- Building type and construction: Factors like building materials, wall framing, and roof structure impact insulation needs.

- Insulation performance: The thermal resistance (R-value) of rock wool insulation determines its effectiveness in reducing heat transfer.

- Building codes and regulations: Local building codes often specify minimum insulation requirements for different building components.

5. What are the key advantages of using rock wool insulation over other materials?

- Excellent thermal insulation: Rock wool’s high thermal resistance effectively reduces heat loss, contributing to energy savings and improved indoor comfort.

- Fire resistance: Rock wool is non-combustible and provides excellent fire protection, enhancing building safety.

- Acoustic insulation: Rock wool’s sound-absorbing properties help mitigate noise transmission, creating quieter and more comfortable indoor environments.

- Water resistance: Unlike fiberglass insulation, rock wool is water-repellent and does not absorb moisture, maintaining its insulation performance even in humid conditions.

- Durability and longevity: Rock wool is highly durable and maintains its insulating properties over time, ensuring long-term performance and building efficiency.

6. Can you explain the process of installing rock wool insulation in a cavity wall?

Installing rock wool insulation in a cavity wall involves several steps:

- Prepare the cavity: Ensure the cavity is clean, dry, and free of debris.

- Cut the insulation: Measure and cut rock wool batts to fit the cavity, accounting for any obstructions.

- Insert the insulation: Carefully insert the batts into the cavity, ensuring they fit snugly and fill any gaps.

- Secure the insulation: Use fasteners or adhesive to secure the insulation in place, preventing it from settling or shifting.

- Seal any gaps: Use expanding foam or caulk to seal any gaps around pipes, wires, or other penetrations to maintain insulation effectiveness.

7. How do you minimize thermal bridging when installing rock wool insulation?

- Use continuous insulation: Install insulation without any gaps or breaks to eliminate thermal bridges.

- Avoid metal fasteners: Metal fasteners can create thermal bridges. Use plastic anchors or straps to secure insulation.

- Insulate around studs: Extend insulation around studs and joists to prevent heat transfer through the framing.

- Seal air leaks: Use caulk or expanding foam to seal air leaks around pipes, wires, and other penetrations.

- Consider using thermal breaks: Thermal breaks, such as rigid foam or gaskets, can be installed between framing members to minimize heat transfer.

8. What are the different techniques used to apply rock wool insulation to curved surfaces?

- Pre-curved batts: Use rock wool batts manufactured with a pre-curved shape to fit curved surfaces.

- Scoring and bending: Score the rock wool batts and carefully bend them to conform to the curved surface.

- Spray-applied rock wool: This method involves spraying a mixture of rock wool fibers and adhesive onto the curved surface, providing a seamless and conforming insulation layer.

- Loose-fill rock wool: Loose-fill rock wool can be applied to curved surfaces by pouring or blowing it into the space, ensuring it fills all gaps and contours.

9. How do you ensure proper air sealing when installing rock wool insulation in an attic?

- Seal around penetrations: Use caulk or expanding foam to seal air leaks around pipes, wires, and other penetrations in the attic floor.

- Install a vapor barrier: Apply a vapor barrier over the insulation to prevent warm, moist air from reaching the cold roof deck and condensing.

- Seal the attic hatch: Install weatherstripping or gaskets around the attic hatch to prevent air leakage.

- Use spray foam: Spray foam can be used to seal gaps and cracks in the attic, providing an effective air barrier.

10. Can you discuss the environmental benefits of using rock wool insulation?

- Reduced energy consumption: Rock wool insulation effectively reduces heat loss, leading to lower energy consumption and reduced greenhouse gas emissions.

- Lower carbon footprint: Rock wool is made from recycled materials, such as basalt and recycled glass, contributing to a lower carbon footprint compared to other insulation materials.

- Sustainable manufacturing: The production of rock wool involves sustainable practices, minimizing waste and using renewable energy sources.

- Recyclable and reusable: Rock wool can be recycled and reused at the end of its life cycle, further reducing its environmental impact.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rock Wool Applicator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rock Wool Applicator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Rock Wool Applicator, you will be responsible for various tasks related to the application of rock wool insulation.

1. Safety and Compliance

Ensure compliance with all safety regulations and guidelines while handling and installing rock wool insulation.

- Wear appropriate safety gear, including gloves, safety glasses, and respirators.

- Handle and store rock wool insulation materials safely to prevent inhalation or skin irritation.

2. Insulation Installation

Apply rock wool insulation to designated areas according to specifications and industry standards.

- Inspect surfaces to be insulated and determine the appropriate insulation thickness and density.

- Cut and shape rock wool insulation to fit the contours of the surface being insulated.

- Secure rock wool insulation using adhesives, fasteners, or mechanical means.

3. Quality Control

Ensure the proper installation of rock wool insulation to meet quality standards.

- Inspect installed insulation for gaps, voids, or other defects.

- Conduct thermal resistance tests to verify the effectiveness of the insulation.

4. Maintenance and Repair

Perform maintenance and repairs on existing rock wool insulation.

- Identify and repair damaged or deteriorated rock wool insulation.

- Replace or repair insulation that has become compromised due to age, moisture, or other factors.

Interview Tips

To prepare for your interview for the Rock Wool Applicator position, consider the following tips:

1. Research the Company and Role

Familiarize yourself with the company’s history, values, and current projects. Read the job description carefully and identify the key responsibilities and requirements.

- Visit the company’s website and social media pages.

- Look up recent news articles or press releases about the company.

2. Showcase Your Skills and Experience

Highlight your relevant skills and experience that align with the job requirements. Quantify your accomplishments whenever possible to demonstrate your impact.

- Provide specific examples of projects where you applied rock wool insulation.

- Discuss your knowledge of insulation materials, techniques, and safety regulations.

3. Emphasize Safety and Quality

Emphasize your commitment to safety and maintaining high-quality standards in your work.

- Share examples of your proactive approach to safety on previous job sites.

- Describe your attention to detail and dedication to ensuring the proper installation of insulation.

4. Prepare Questions to Ask

Prepare thoughtful questions to ask the interviewer about the company, the role, or the industry. This shows your engagement and interest in the position.

- Ask about the company’s current insulation projects and upcoming initiatives.

- Inquire about the opportunities for professional development and growth within the organization.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Rock Wool Applicator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.