Are you gearing up for a career in Refrigeration Plant Cork Insulator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Refrigeration Plant Cork Insulator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

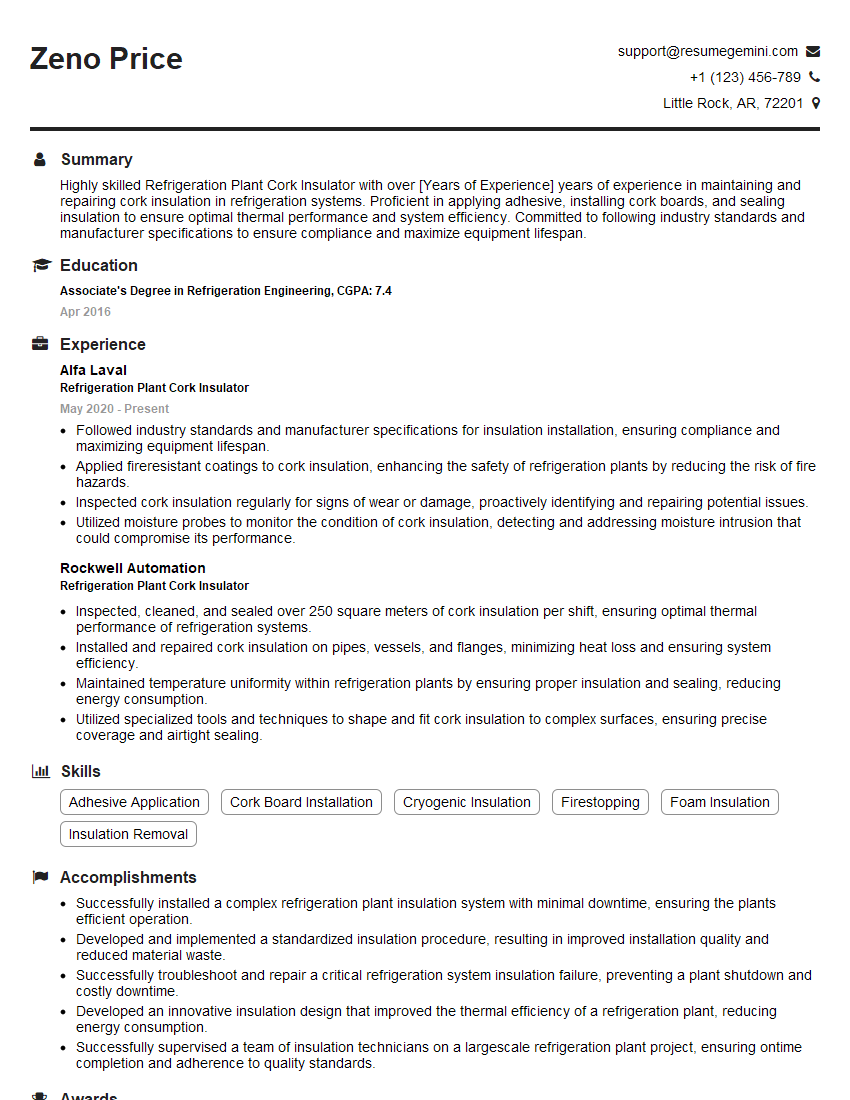

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Refrigeration Plant Cork Insulator

1. Describe the steps involved in installing cork insulation on a refrigeration plant?

Steps Involved in Installing Cork Insulation:

- Prepare the surface: Clean and smooth the surface to ensure a proper bond.

- Apply adhesive: Apply a layer of adhesive to the surface.

- Install cork sheets: Place the cork sheets in rows, ensuring tight joints and proper alignment.

- Apply sealant: Fill in any gaps or joints with a sealant to prevent moisture penetration.

- Test and inspect: Conduct pressure and leak tests to ensure proper installation.

2. What are the different types of cork used for insulation, and what are their advantages and disadvantages?

Types of Cork for Insulation:

- Regular cork:

- Advantages: Lightweight, fire-resistant

- Disadvantages: Prone to moisture absorption

- Expanded cork:

- Advantages: Excellent thermal insulation, water-resistant

- Disadvantages: More expensive than regular cork

- Extruded cork:

- Advantages: Closed-cell structure, high thermal resistance

- Disadvantages: Less flexible than other types

3. What are the safety precautions to consider when working with cork insulation?

- Wear protective gear: Gloves, safety glasses, and a mask.

- Handle with care: Cork sheets can be sharp or brittle.

- Avoid dust inhalation: Cork dust can cause respiratory irritation.

- Dispose of properly: Cork insulation is combustible, so dispose of it according to local regulations.

4. How do you determine the appropriate thickness of cork insulation for a refrigeration plant?

- Consider ambient temperature: Thicker insulation is required in warmer climates.

- Calculate desired thermal resistance (R-value): Determine the required insulation value based on local building codes and plant requirements.

- Refer to manufacturer’s specifications: Different cork types have varying R-values per unit thickness.

5. What are the common maintenance practices for cork insulation in refrigeration plants?

- Inspect regularly: Check for damage, moisture accumulation, or gaps in the insulation.

- Clean and repair: Remove any debris or dirt, and seal any cracks or tears.

- Monitor temperature and humidity: Ensure proper insulation performance by monitoring temperature and humidity levels.

6. How do you assess the effectiveness of cork insulation in a refrigeration plant?

- Monitor energy consumption: Compare energy usage before and after insulation installation.

- Conduct thermal imaging: Identify areas with potential heat loss or cold gain.

- Measure temperature differentials: Track temperature changes across the insulated areas.

7. What are the environmental benefits of using cork insulation?

- Natural and renewable resource: Cork is harvested from cork oak trees without harming the environment.

- Biodegradable and recyclable: Cork insulation can be disposed of in an environmentally friendly way.

- Low embodied energy: Cork requires less energy to produce compared to other insulation materials.

8. What are the challenges associated with cork insulation, and how do you mitigate them?

- Moisture absorption: Apply sealants and use water-resistant cork types.

- Fire resistance: Treat cork with flame retardants or use fire-resistant coatings.

- Cost: Explore cost-effective cork insulation options or consider government incentives.

9. How do you stay up-to-date with advancements in cork insulation technology?

- Attend industry conferences: Network and learn about the latest developments.

- Read trade publications and journals: Stay informed about innovative insulation techniques and products.

- Consult with manufacturers and experts: Seek advice on the latest insulation technologies and best practices.

10. Why are you interested in the Refrigeration Plant Cork Insulator position at our company?

Reasons for Interest:

- Passion for thermal insulation: I am enthusiastic about the role of insulation in energy efficiency and environmental sustainability.

- Experience and expertise: My background in cork insulation installation and maintenance makes me a suitable candidate for this position.

- Alignment with company values: Your company’s commitment to innovation and quality aligns with my professional aspirations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Refrigeration Plant Cork Insulator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Refrigeration Plant Cork Insulator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Refrigeration Plant Cork Insulators are responsible for installing and maintaining cork insulation in refrigeration plants. Their primary duties include:

1. Insulation Installation

Installing cork insulation on pipes, tanks, and other surfaces to prevent heat loss and maintain desired temperatures.

- Calculating material requirements and cutting cork sheets to the appropriate dimensions.

- Applying adhesive to surfaces and attaching cork sheets securely.

- Sealing joints and seams to prevent air infiltration.

2. Insulation Maintenance

Inspecting and repairing cork insulation to ensure its integrity and effectiveness.

- Identifying damaged or deteriorated insulation and replacing it as needed.

- Cleaning and repairing insulation surfaces to prevent contamination and moisture buildup.

- Performing regular inspections to monitor the condition of the insulation and identify potential problems.

3. Equipment Operation

Operating equipment necessary for the installation and maintenance of cork insulation.

- Using power tools, such as saws, drills, and hammers.

- Operating adhesive applicators and other specialized equipment.

- Ensuring the proper functioning and safe operation of equipment.

4. Safety and Compliance

Adhering to safety regulations and protocols while performing insulation work.

- Wearing appropriate safety gear, such as gloves, goggles, and protective clothing.

- Following established procedures for handling and storing hazardous materials.

- Maintaining a clean and organized work area to prevent accidents.

Interview Tips

To ace an interview for a Refrigeration Plant Cork Insulator position, consider these tips:

1. Research the Company and Role

Familiarize yourself with the company’s operations and the specific requirements of the job. This knowledge will help you tailor your answers to the interviewer’s questions and demonstrate your understanding of the role.

2. Highlight Relevant Skills and Experience

Emphasize your experience in installing and maintaining cork insulation in refrigeration plants. Provide specific examples of projects you have worked on and the techniques you employed.

3. Demonstrate Safety Awareness

Stress your adherence to safety protocols and your understanding of the importance of maintaining a safe work environment. Describe your experience with handling hazardous materials and operating equipment safely.

4. Ask Informed Questions

At the end of the interview, prepare thoughtful questions about the company, the position, or the industry. This shows your interest and engagement and can leave a positive impression on the interviewer.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Refrigeration Plant Cork Insulator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.