Are you gearing up for an interview for a Colored Liquid Plastic Applier position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Colored Liquid Plastic Applier and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

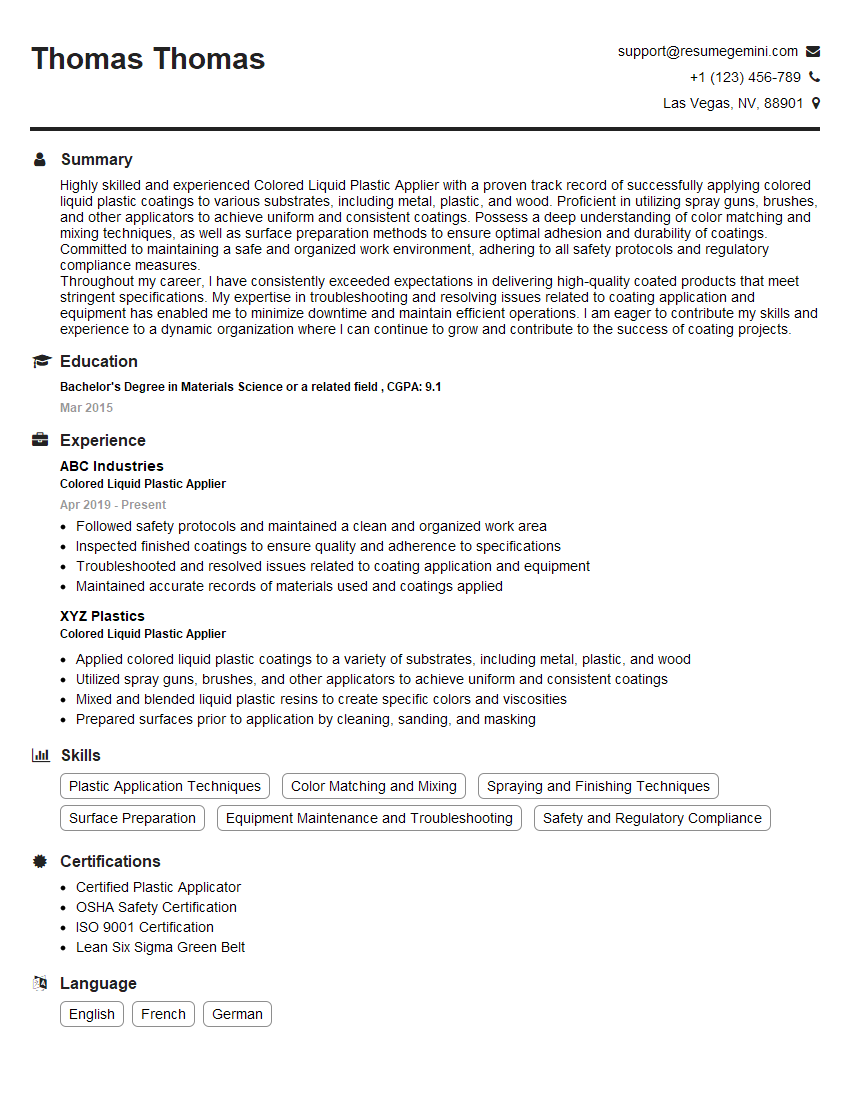

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Colored Liquid Plastic Applier

1. What are the key steps involved in applying colored liquid plastic?

The key steps involved in applying colored liquid plastic are:

- Prepare the surface by cleaning and removing any contaminants.

- Mix the colored liquid plastic according to the manufacturer’s instructions.

- Apply the colored liquid plastic to the surface using a brush, roller, or spray gun.

- Allow the colored liquid plastic to cure for the specified amount of time.

- Inspect the finished product to ensure that it meets the desired specifications.

2. What are the different types of colored liquid plastics available?

Thermoplastics

- Can be melted and remolded multiple times without chemical change

- Examples: polyethylene, polypropylene, polystyrene

Thermosets

- Undergo an irreversible chemical change when heated, forming a rigid and cross-linked structure

- Examples: epoxy, polyester, phenolic

Elastomers

- Exhibit rubbery properties and can be stretched and returned to their original shape

- Examples: natural rubber, silicone, polyurethane

3. What are the advantages of using colored liquid plastic?

- Excellent adhesion to a variety of surfaces

- Durable and resistant to wear and tear

- Resistant to chemicals and solvents

- Available in a wide range of colors and finishes

- Can be used to create complex shapes and designs

4. What are the disadvantages of using colored liquid plastic?

- Can be expensive compared to other materials

- Requires specialized equipment and training to apply

- Can be difficult to remove once it has cured

- Can release harmful fumes during application and curing

5. What safety precautions should be taken when working with colored liquid plastic?

- Wear appropriate personal protective equipment, including gloves, safety glasses, and a respirator

- Work in a well-ventilated area

- Follow all manufacturer’s instructions for safe handling and disposal

6. What are the common applications of colored liquid plastic?

- Automotive parts

- Medical devices

- Consumer electronics

- Construction materials

- Furniture and fixtures

7. What are the challenges of working with colored liquid plastic?

- Achieving a consistent and uniform finish

- Preventing drips and runs

- Working with complex shapes and designs

- Ensuring proper adhesion to the surface

- Meeting safety and environmental regulations

8. What are the latest trends in colored liquid plastic technology?

- Development of new and improved formulations

- Introduction of new colors and finishes

- Advancements in application techniques

- Increasing use of sustainable and eco-friendly materials

9. What is the future of colored liquid plastic?

Colored liquid plastic is a versatile and innovative material with a wide range of applications. As technology continues to advance, we can expect to see even more new and innovative uses for this material in the years to come.

10. Describe your experience working with colored liquid plastic.

In my previous role, I was responsible for applying colored liquid plastic to a variety of products, including automotive parts, medical devices, and consumer electronics. I have experience with a variety of application techniques, including brushing, rolling, and spraying. I am also familiar with the safety precautions that must be taken when working with colored liquid plastic.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Colored Liquid Plastic Applier.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Colored Liquid Plastic Applier‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Colored Liquid Plastic Applier is responsible for applying colored liquid plastic to various surfaces. This role plays a crucial part in the production process, ensuring the accurate and efficient application of liquid plastic.

1. Preparation and Equipment Setup

Before applying liquid plastic, the applier must prepare the work area and set up the necessary equipment. This includes gathering materials, cleaning and sanitizing work surfaces, and ensuring that all equipment is in good working order.

- Gather necessary materials, including liquid plastic, spray guns, and protective gear.

- Clean and sanitize work surfaces to prevent contamination.

- Inspect and prepare spray guns, ensuring proper operation and calibration.

2. Liquid Plastic Application

The applier’s primary responsibility is to apply colored liquid plastic to surfaces according to specifications. This involves operating spray guns, controlling the flow and thickness of the applied plastic, and ensuring uniform coverage.

- Operate spray guns to apply liquid plastic evenly and accurately.

- Control the flow and thickness of the applied plastic to achieve desired results.

- Ensure uniform coverage and avoid defects or inconsistencies in the applied plastic.

3. Quality Control and Inspection

To ensure the quality of the applied plastic, the applier must conduct regular inspections and monitor the application process. This includes visually inspecting surfaces for defects, checking the thickness and uniformity of the plastic, and addressing any issues promptly.

- Visually inspect applied plastic for defects, such as runs, drips, or bubbles.

- Measure and check the thickness and uniformity of the applied plastic using gauges.

- Identify and resolve any issues or inconsistencies in the application process promptly.

4. Maintenance and Cleaning

Regular maintenance and cleaning of equipment are essential for the smooth operation and longevity of the application process. The applier is responsible for cleaning spray guns, maintaining equipment, and ensuring the work area is kept clean and organized.

- Clean spray guns thoroughly after each use to prevent clogging or damage.

- Perform regular maintenance on equipment, including lubrication, calibration, and repairs.

- Maintain a clean and organized work area to ensure safety and efficiency.

Interview Tips

Preparing for an interview for a Colored Liquid Plastic Applier position requires a combination of technical knowledge and a demonstration of your skills and experience. Here are some tips to help you ace the interview:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific position. Understand the company’s products, services, and industry standing. Additionally, review the job description carefully to identify the key responsibilities and qualifications required.

- Visit the company’s website to gather information about their business and culture.

- Read industry publications and articles to stay informed about the latest trends and technologies.

2. Highlight Your Technical Expertise

Emphasize your technical knowledge and experience in applying colored liquid plastic. Discuss your understanding of different types of liquid plastic, spray gun operation, and quality control techniques. Provide specific examples of your work and quantify your results whenever possible.

- Describe your experience with various types of liquid plastic and their properties.

- Explain your proficiency in operating and calibrating spray guns for precise application.

- Discuss your methods for ensuring the quality and uniformity of the applied plastic.

3. Showcase Your Attention to Detail

Attention to detail is crucial in this role. Highlight your ability to focus on precision, accuracy, and consistency in your work. Provide examples of how you have maintained high standards and met or exceeded quality expectations in previous positions.

- Describe your experience in visually inspecting applied plastic for defects and inconsistencies.

- Explain your methods for measuring and controlling the thickness and uniformity of the applied plastic.

4. Emphasize Your Safety and Maintenance Skills

Safety and maintenance are essential aspects of this role. Demonstrate your understanding of safety protocols and your ability to maintain equipment in good working order. Highlight your experience in following safety guidelines, performing regular maintenance, and troubleshooting equipment issues.

- Discuss your experience in following safety protocols and using personal protective equipment.

- Describe your proactive approach to equipment maintenance and your ability to identify and resolve issues promptly.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Colored Liquid Plastic Applier interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!