Feeling lost in a sea of interview questions? Landed that dream interview for Line Painting Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Line Painting Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

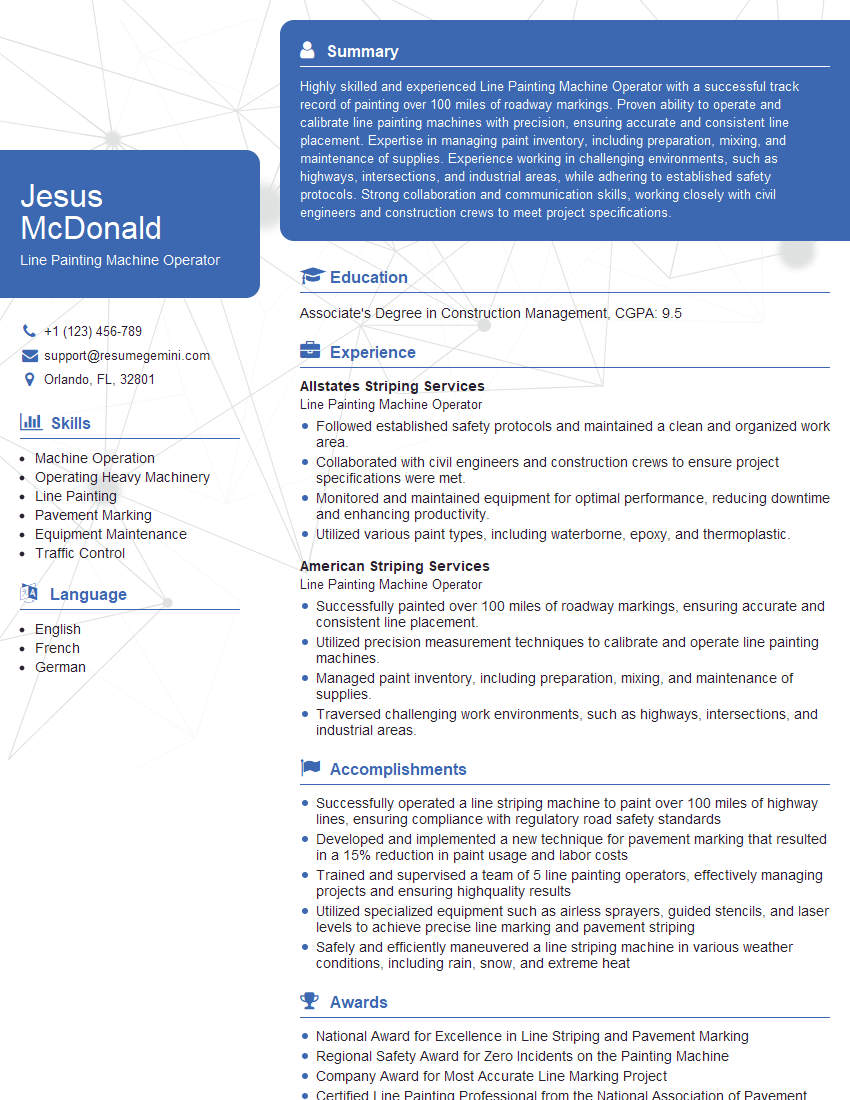

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Line Painting Machine Operator

1. What are the key elements of line striping machine maintenance?

Here are the key elements of line striping machine maintenance:

- Regular lubrication of all moving parts, including bearings, gears, and chains.

- Inspecting and replacing worn or damaged parts.

- Cleaning the machine regularly to remove dirt and debris.

- Storing the machine in a dry, protected place when not in use.

2. What are the safety precautions you should take when operating a line striping machine?

Personal Protective Equipment

- Wear appropriate safety gear, including gloves, safety glasses, and a hard hat.

- Wear high-visibility clothing to enhance visibility.

Machine Operation

- Inspect the machine before each use to ensure it is in good working condition.

- Operate the machine on a stable and level surface.

- Be aware of your surroundings and avoid obstacles.

- Never operate the machine while under the influence of drugs or alcohol.

3. How do you ensure that the line striping machine is calibrated correctly?

Here are some steps to ensure proper calibration of a line striping machine:

- Refer to the manufacturer’s instructions for specific calibration procedures.

- Check the accuracy of the measuring wheel or sensor to ensure it is providing the correct distance measurement.

- Adjust the paint flow rate and pressure according to the desired line width and thickness.

- Test the machine on a sample surface before starting the actual striping process.

4. What are the common troubleshooting techniques for line striping machines?

- Clogged Nozzles: Clean or replace clogged nozzles to ensure proper paint flow.

- Uneven Lines: Adjust the machine’s alignment, check for worn parts, or calibrate the steering system.

- Skipping Lines: Inspect the paint supply and ensure there are no blockages. Check the pump pressure and adjust if necessary.

- Fading Lines: Adjust the paint dilution ratio or use higher-quality paint.

- Engine Problems: Refer to the manufacturer’s instructions for troubleshooting engine issues.

5. How do you handle different types of surfaces when line striping?

- Asphalt: Use fast-drying paints and ensure the surface is clean and free of debris.

- Concrete: Allow ample drying time and consider using primers or bonding agents.

- Brick or Pavers: Use specialized paints and techniques to ensure adhesion and longevity.

- Curbs and Walls: Use appropriate paints and stencils for crisp and clear markings.

6. What are the environmental considerations when using line striping machines?

- Use environmentally friendly paints and solvents.

- Dispose of waste materials properly according to local regulations.

- Minimize noise pollution by using machines with noise-reducing features.

- Avoid operating machines during sensitive hours or in areas with noise restrictions.

7. How do you ensure the quality and accuracy of line striping?

- Plan and mark the layout carefully before striping.

- Use high-quality paints and materials.

- Calibrate and maintain the machine regularly.

- Apply the paint evenly and at a consistent speed.

- Allow ample drying time before reopening the area.

8. What are the different types of line striping patterns?

- Solid Lines: Continuous lines used for lane separation, crosswalks, and parking spaces.

- Dashed Lines: Intermittent lines indicating areas where passing or parking is allowed.

- Skip Lines: Dashed lines with longer gaps, often used in areas with high pedestrian traffic.

- Arrows: Directional markings used at intersections and roundabouts.

- Symbols: Markings representing parking zones, no-stopping areas, and other traffic regulations.

9. How do you manage hazardous materials used in line striping?

- Store materials in a secure and well-ventilated area.

- Wear appropriate protective gear when handling materials.

- Follow manufacturer’s instructions for proper mixing and application.

- Dispose of leftover materials and empty containers according to regulations.

- Train employees on hazardous material handling protocols.

10. What are your preferred methods for communicating with clients and supervisors?

I prefer to communicate with clients and supervisors in a clear and responsive manner. Here are my preferred methods of communication:

- Email: For formal communication, providing detailed updates and documentation.

- Phone: For quick discussions, urgent inquiries, or when a prompt response is required.

- In-Person Meetings: For important project discussions, presentations, or resolving complex issues.

- Project Management Software: For task management, file sharing, and tracking project progress.

- Instant Messaging: For brief updates, quick questions, or when immediate attention is needed.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Line Painting Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Line Painting Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Line Painting Machine Operators are responsible for the efficient and accurate operation of line painting machines. They must be able to work independently and as part of a team, and have a strong attention to detail. Key job responsibilities include:

1. Machine Operation

- Load and unload paint, stencils, and other materials

- Operate the machine to apply paint to surfaces

- Monitor the machine’s operation and make adjustments as needed

- Inspect the finished product and ensure that it meets quality standards

2. Maintenance and Repair

- Perform routine maintenance on the machine

- Identify and troubleshoot any problems with the machine

- Make minor repairs as needed

- Report any major problems to a supervisor

3. Safety and Compliance

- Follow all safety regulations

- Wear appropriate personal protective equipment

- Dispose of hazardous materials properly

- Maintain a clean and organized work area

4. Communication and Teamwork

- Communicate effectively with supervisors, co-workers, and customers

- Work as part of a team to achieve common goals

- Provide feedback on the machine’s operation and suggest improvements

- Participate in training and development programs

Interview Tips

Preparing for a job interview can be stressful, but there are a few things you can do to increase your chances of success.

1. Research the company and the position

- Visit the company’s website to learn about their history, mission, and values.

- Read the job description carefully and make a list of the key skills and qualifications.

- Identify any specific experience or training that you have that is relevant to the position.

2. Practice your answers to common interview questions

- Prepare answers to questions about your experience, skills, and qualifications.

- Practice answering questions about your weaknesses and your goals.

- Come up with questions to ask the interviewer about the company and the position.

3. Dress professionally and arrive on time

- First impressions matter, so make sure you dress professionally and arrive on time for your interview.

- Be polite and respectful to everyone you meet, including the receptionist and other employees.

- Bring a copy of your resume and any other relevant materials.

4. Be yourself and be confident

- The most important thing is to be yourself and be confident.

- Don’t try to be someone you’re not, because the interviewer will be able to tell.

- Be honest about your experience and skills, and be prepared to talk about your strengths and weaknesses.

Next Step:

Now that you’re armed with the knowledge of Line Painting Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Line Painting Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini