Are you gearing up for a career in Cast-Iron Drain Pipe Layer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Cast-Iron Drain Pipe Layer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

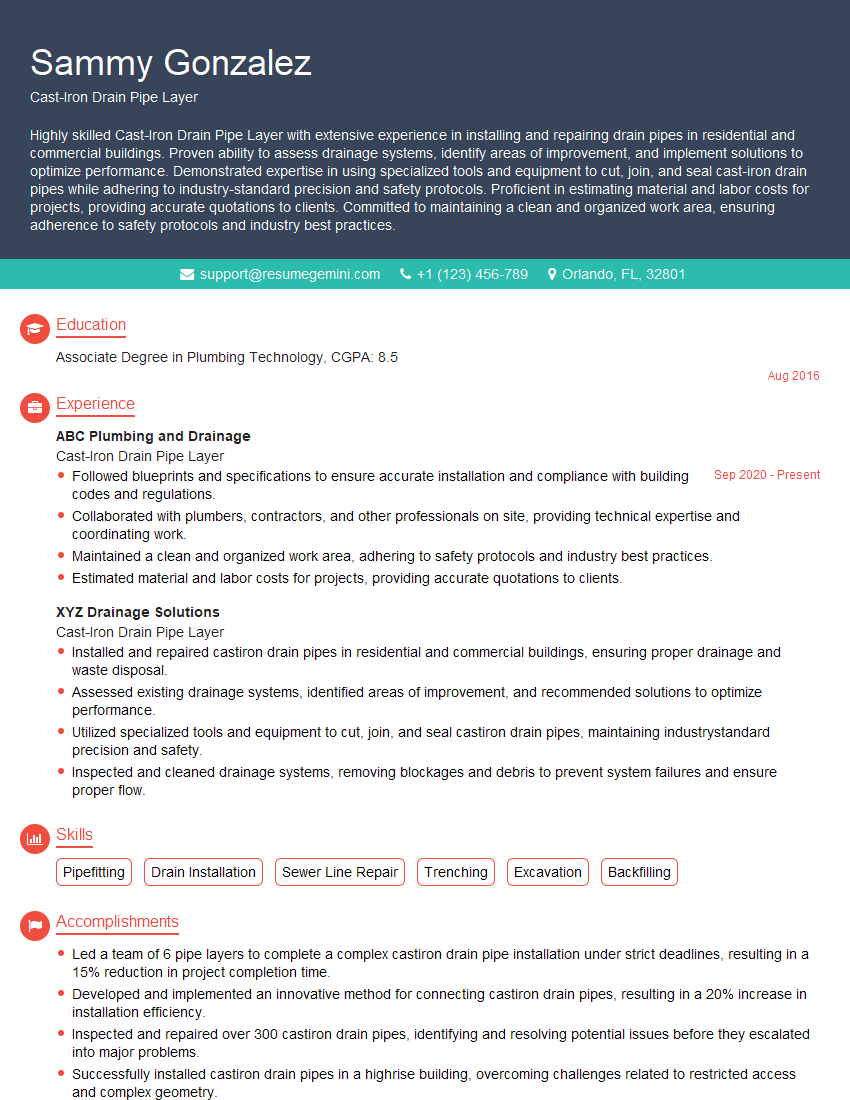

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cast-Iron Drain Pipe Layer

1. Describe the process of installing a cast-iron drain pipe?

The process of installing a cast-iron drain pipe involves several key steps:

- Planning and Layout: Determine the location and route of the pipe, ensuring proper drainage and alignment.

- Excavation: Dig a trench deep enough to accommodate the pipe, with a slight slope for drainage.

- Pipe Preparation: Prepare the cast-iron pipe by cleaning any debris, applying a joint sealant, and assembling the pipe sections using bolts.

- Installation: Lower the pipe assembly into the trench, aligning and leveling it properly.

- Jointing: Connect the pipe sections using bolted or mechanical joints, ensuring watertight connections.

- Backfilling: Cover the installed pipe with excavated soil, compacting it to provide support and prevent settling.

- Testing: Perform a water or air pressure test to ensure proper drainage and identify any leaks.

2. What are the different types of fittings used in cast-iron drain pipe systems?

Standard Fittings

- Bends: Used to change the direction of the pipe

- Tees: Used to connect three pipes together

- Crosses: Used to connect four pipes together

- Reducers: Used to connect pipes of different diameters

Specialty Fittings

- Cleanouts: Provide access for cleaning and inspection

- Traps: Prevent sewer gases from entering the building

- Backwater Valves: Prevent sewage from backing up into the building

3. How do you handle the weight and fragility of cast-iron drain pipes?

Handling cast-iron drain pipes requires care and proper techniques to prevent damage:

- Lifting: Use proper lifting equipment or a team of individuals to lift heavy pipes safely.

- Protective Gear: Wear gloves and safety glasses to protect from sharp edges and fragments.

- Support: Use slings, straps, or padded supports to prevent pipes from bending or cracking.

- Handling: Avoid dragging or dropping pipes. Instead, carefully carry or roll them on a flat surface.

- Storage: Store pipes in a dry, well-ventilated area to prevent rust and corrosion.

4. What are the common challenges encountered during cast-iron drain pipe installation, and how do you overcome them?

- Uneven Trench: Use levelers or adjust the pipe alignment to ensure proper drainage.

- Misaligned Joints: Check the alignment of the pipe sections before connecting them and use hydraulic jacks to adjust.

- Leaks: Inspect joints for proper sealing and ensure bolts are tightened securely. Apply sealant or gaskets as needed.

- Root Penetration: Install root barriers around the pipes to prevent root growth and damage.

- Corrosion: Protect pipes from moisture and acidic soils using coatings or cathodic protection systems.

5. What tools and equipment are essential for a Cast-Iron Drain Pipe Layer?

- Pipe Wrench: For assembling and tightening joints

- Adjustable Hammer: For adjusting and checking joints

- Caulking Gun: For applying sealants and gaskets

- Laser Level: For checking pipe alignment

- Excavation Equipment: Shovel, pickaxe, or backhoe

- Safety Gear: Gloves, safety glasses, hard hat

6. How do you measure and cut cast-iron drain pipes accurately?

To measure and cut cast-iron drain pipes accurately:

- Measurement: Use a tape measure to determine the precise length of the pipe section needed.

- Marking: Mark the cutting point with a chalk line or pencil.

- Cutting: Use an abrasive saw or heavy-duty pipe cutter to cut the pipe at the marked point, ensuring a clean and straight cut.

- Deburring: Remove any burrs or sharp edges from the cut ends using a grinder or file.

7. What safety precautions should be taken when working with cast-iron drain pipes?

- Wear appropriate safety gear, including gloves, safety glasses, and hard hat.

- Be aware of the weight and fragility of the pipes.

- Use proper lifting techniques to avoid injuries.

- Follow proper trenching and excavation safety protocols.

- Inspect pipes for damage before handling or installing them.

8. How do you ensure the proper drainage and alignment of cast-iron drain pipes?

- Use a laser level to check the slope of the pipe and ensure proper drainage.

- Adjust the alignment of the pipes using hydraulic jacks or pipe supports.

- Check the connections between the pipes to prevent leaks and ensure watertight joints.

- Consider the location of fixtures and appliances to ensure proper flow and drainage.

9. What are the different types of cast-iron drain pipe coatings, and how do they affect the performance of the pipes?

Types of Coatings

- Bituminous Coating: Provides corrosion resistance and protection from moisture.

- Epoxy Coating: Highly resistant to chemicals and abrasion, suitable for harsh environments.

- Polyurethane Coating: Offers excellent protection against corrosion, abrasion, and impact damage.

Performance Effects

- Enhanced Durability: Coatings extend the lifespan of the pipes by protecting against corrosion and wear.

- Improved Flow Rates: Smooth coatings reduce friction and improve water flow efficiency.

- Noise Reduction: Coatings absorb sound and reduce noise levels associated with water flow.

10. How do you maintain cast-iron drain pipes to prevent clogs and leaks?

- Regular Cleaning: Use drain snakes or hydro-jetting to remove clogs and buildup.

- Proper Use: Avoid disposing of grease, solids, or chemicals that can cause blockages.

- Inspection: Check pipes periodically for leaks or damage and address them promptly.

- Corrosion Protection: Apply protective coatings or use cathodic protection systems to prevent rust and corrosion.

- Root Barrier Installation: Prevent root penetration by installing root barriers around the pipes.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cast-Iron Drain Pipe Layer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cast-Iron Drain Pipe Layer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Cast-Iron Drain Pipe Layer is an essential part of a construction team, responsible for the proper installation and maintenance of cast-iron drain pipes. Key job responsibilities include:

1. Installation of Drain Pipes

Laying, connecting, and securing cast-iron drain pipes using various fittings, such as elbows, tees, and couplings.

2. Inspection and Maintenance

Regularly inspecting the installed drain pipes for damage, leaks, or blockages. Performing necessary maintenance activities, such as repairs, replacements, and cleaning.

3. Adherence to Building Codes

Ensuring that all drain pipe installations adhere to applicable building codes and industry standards.

4. Collaboration with Contractors

Working closely with other contractors to coordinate the installation of drain pipes within the overall construction schedule.

Interview Preparation Tips

Interview preparation is crucial for a successful interview. Here are some tips and hacks to help candidates ace the interview for a Cast-Iron Drain Pipe Layer position:

1. Research the Company and Position

Familiarize yourself with the company’s business, values, and the specific requirements of the Cast-Iron Drain Pipe Layer role.

2. Practice Common Interview Questions

Prepare for questions related to your experience in drain pipe installation, maintenance, and code compliance. Consider using the STAR method (Situation, Task, Action, Result) to structure your answers and provide concrete examples.

3. Demonstrate Knowledge of Industry Standards

Show that you are knowledgeable about industry standards and codes related to drain pipe installation. Mention any certifications or training you have received.

4. Safety and Attention to Detail

Cast-Iron Drain Pipe Layer positions require a strong focus on safety and attention to detail. Highlight your commitment to safety and your ability to work meticulously.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Cast-Iron Drain Pipe Layer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.