Are you gearing up for an interview for a Pipe Assembly Worker position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Pipe Assembly Worker and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

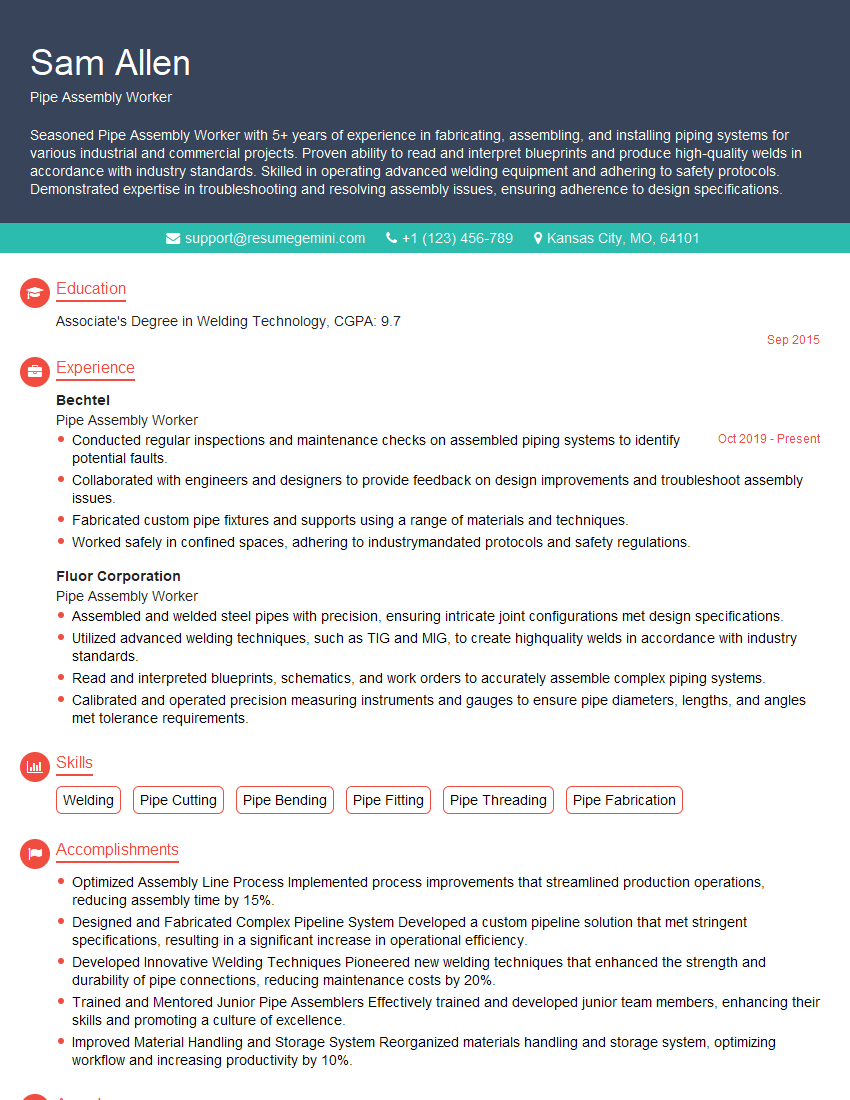

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pipe Assembly Worker

1. Describe the steps involved in assembling a pipe system.

- Plan the layout of the pipe system.

- Cut the pipes to the required length.

- Deburr the ends of the pipes.

- Apply flux to the ends of the pipes.

- Solder the pipes together.

- Pressure test the pipe system.

2. What are the different types of pipe joints?

- Butt joint

- Socket joint

- Flange joint

- Screwed joint

- Welded joint

3. What are the different types of pipe materials?

- Copper

- Brass

- Steel

- PVC

- CPVC

4. What are the different types of pipe fittings?

- Elbows

- Tees

- Crosses

- Bushings

- Reducers

5. What are the safety precautions that should be taken when working with pipes?

- Wear appropriate safety gear, including gloves, safety glasses, and a hard hat.

- Be aware of the location of electrical lines and other hazards.

- Use proper tools and equipment.

- Follow all safety procedures.

6. What are the troubleshooting steps for a leaking pipe?

- Tighten the connections.

- Replace the washers.

- Replace the pipe.

7. What are the maintenance steps for a pipe system?

- Inspect the pipes for leaks.

- Clean the pipes.

- Flush the pipes.

- Test the pipes.

8. What is the difference between a pipe and a tube?

9. What is the difference between a fitting and a valve?

10. What is the difference between a union and a flange?

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pipe Assembly Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pipe Assembly Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pipe Assembly Workers play a critical role in various industries, including construction, manufacturing, and plumbing. Their primary tasks involve assembling, installing, and repairing pipes and related components to create functional systems that transport fluids, gases, or other materials.

1. Assembly and Installation

Pipe Assembly Workers are responsible for assembling and installing pipes, fittings, valves, and other components to create piping systems. They use specialized tools and techniques to connect pipes, ensuring proper alignment and tightness. They may also install fixtures, such as sinks, toilets, and faucets, as part of the installation process.

- Assemble and install pipes, fittings, valves, and other components according to blueprints and specifications.

- Use specialized tools and equipment, such as pipe cutters, threaders, and welding equipment, to fabricate and connect pipes.

- Ensure proper alignment, tightness, and functionality of piping systems.

2. Maintenance and Repair

Pipe Assembly Workers perform routine maintenance and repairs on piping systems. They inspect systems for leaks, blockages, and other issues. They use their expertise to identify and resolve problems, ensuring the proper functioning of the systems.

- Inspect piping systems for leaks, blockages, and other problems.

- Diagnose and resolve issues using specialized tools and techniques.

- Replace or repair damaged or faulty pipes and components.

3. Safety Compliance

Pipe Assembly Workers must adhere to strict safety protocols to ensure their own safety and the safety of others. They are responsible for following safety guidelines, wearing appropriate protective gear, and using proper equipment. They also need to be aware of potential hazards associated with pipes and piping systems.

- Follow safety protocols and wear appropriate protective gear.

- Operate equipment safely and in accordance with established procedures.

- Be aware of potential hazards and take appropriate precautions.

4. Communication and Teamwork

Pipe Assembly Workers often work as part of a team and must be able to communicate effectively with colleagues, supervisors, and clients. They need to be able to understand and interpret blueprints and specifications, as well as provide clear instructions to others.

- Communicate effectively with colleagues, supervisors, and clients.

- Understand and interpret blueprints and specifications.

- Provide clear instructions to others and work effectively as part of a team.

Interview Tips

Preparing for an interview for a Pipe Assembly Worker position can increase your chances of making a strong impression and landing the job. Here are some tips to help you ace the interview:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific position you are applying for. This will show the interviewer that you are genuinely interested in the opportunity and that you have taken the time to learn about their company. It will also help you answer questions intelligently and demonstrate your enthusiasm for the role.

- Visit the company’s website to learn about their products or services, history, and culture.

- Review the job description thoroughly to understand the key responsibilities and qualifications.

- Research industry trends and best practices related to pipe assembly to stay up-to-date on the latest techniques.

2. Practice Your Answers

Take some time to practice answering common interview questions. This will help you develop clear and concise responses that highlight your skills and experience. You can practice with a friend, family member, or career counselor. It can also be helpful to write down your answers and review them before the interview.

- Prepare for questions about your experience with pipe assembly, welding, and other relevant skills.

- Be ready to discuss your knowledge of pipe materials, fittings, and safety procedures.

- Practice describing your problem-solving abilities and how you handle technical challenges.

3. Bring a Positive Attitude

A positive attitude can go a long way in an interview. Be enthusiastic and professional, and demonstrate your willingness to learn and contribute to the team. A positive attitude can make you more memorable and increase your chances of getting the job.

- Greet the interviewer with a firm handshake and make eye contact.

- Smile and be friendly, but maintain a professional demeanor.

- Be confident in your abilities and show that you are eager to take on new challenges.

4. Follow Up

After the interview, it is important to follow up with the interviewer. This shows that you are still interested in the position and that you appreciate the opportunity to interview. A follow-up email or phone call can also be an opportunity to reiterate your interest and highlight any key points from the interview.

- Send a thank-you email within 24 hours of the interview.

- Reiterate your interest in the position and thank the interviewer for their time.

- If there is any additional information you would like to provide, include it in the follow-up message.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Pipe Assembly Worker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!