Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Product Inspection Coordinator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

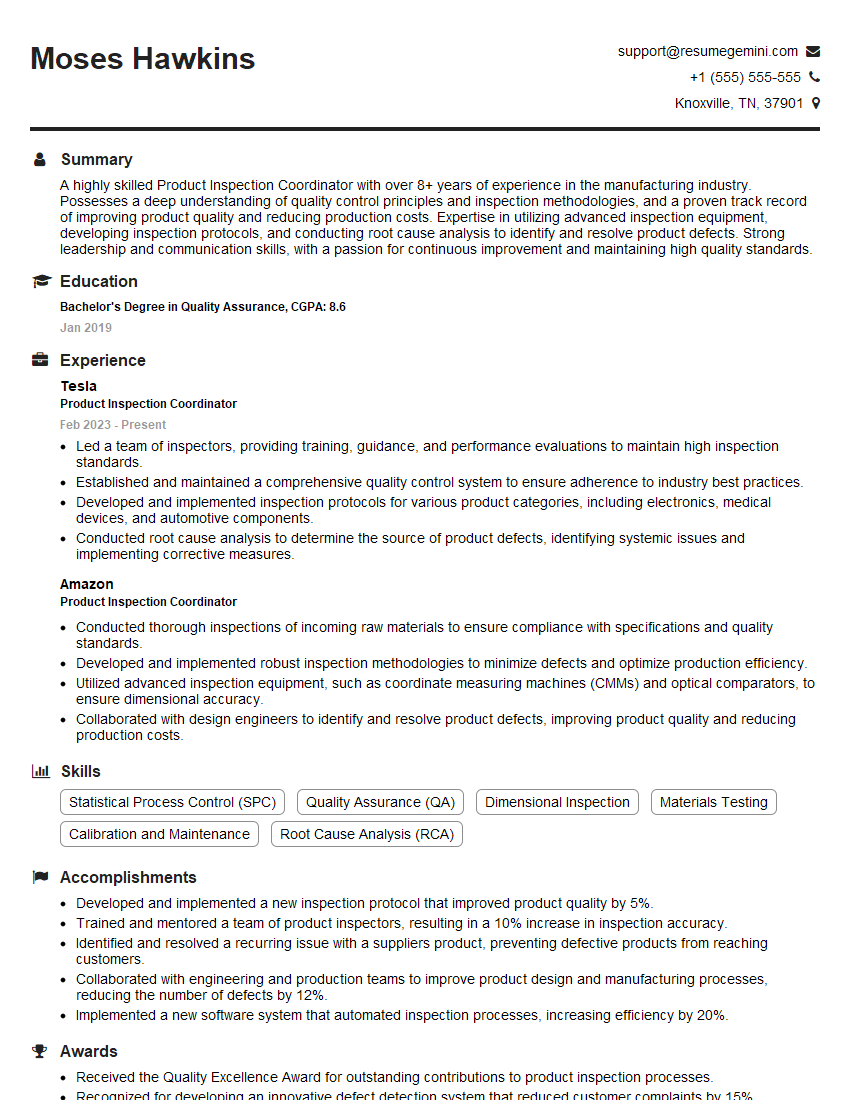

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Product Inspection Coordinator

1. How do you ensure that the products meet the required specifications and quality standards?

To ensure that the products meet the required specifications and quality standards, I follow a comprehensive process:

- Review product specifications and quality requirements.

- Develop inspection plans and procedures based on the requirements.

- Conduct thorough product inspections using appropriate inspection techniques and equipment.

- Identify and document any defects or non-conformances.

- Monitor and evaluate the quality of products.

- Provide feedback to relevant departments for corrective actions.

2. What are the different types of inspection methods used in product inspection? Briefly describe each method.

Visual Inspection:

- Examining products visually for defects, damage, or deviations from specifications.

- Used for surface defects, dimensional accuracy, and labeling verification.

Dimensional Inspection:

- Using measuring instruments to verify product dimensions meet specifications.

- Includes gauging, micrometers, calipers, and coordinate measuring machines.

Functional Testing:

- Testing product functionality to ensure it operates as intended.

- May involve simulating real-world conditions or using specialized testing equipment.

Statistical Sampling:

- Inspecting a representative sample of products to estimate the quality of the entire lot.

- Used when 100% inspection is impractical.

Non-Destructive Testing (NDT):

- Using specialized techniques to inspect products without causing damage.

- Includes ultrasonic testing, radiography, and eddy current testing.

3. How do you handle discrepancies or defects identified during product inspection?

When discrepancies or defects are identified during product inspection, I follow these steps:

- Identify and document the discrepancy/defect clearly.

- Trace the product’s history to identify potential causes.

- Communicate the findings to relevant departments, including quality control, production, and engineering.

- Work with cross-functional teams to develop and implement corrective actions.

- Monitor the effectiveness of corrective actions to prevent recurrence.

4. What are your responsibilities in managing and maintaining inspection equipment and instruments?

My responsibilities in managing and maintaining inspection equipment and instruments include:

- Regularly calibrate and maintain equipment to ensure accuracy and reliability.

- Troubleshoot and resolve equipment issues to minimize downtime.

- Keep detailed records of equipment use, maintenance, and calibration.

- Stay updated on the latest inspection equipment and technologies.

- Train and supervise team members on proper equipment handling.

5. How do you ensure that inspection data is accurate, reliable, and traceable?

To ensure that inspection data is accurate, reliable, and traceable, I employ the following measures:

- Adhere to established inspection procedures and protocols.

- Use calibrated and well-maintained equipment for data acquisition.

- Record inspection data accurately and consistently.

- Implement a data traceability system to link inspection results to specific products and batches.

- Review and verify inspection data before reporting it.

6. What are the industry best practices for product inspection?

The industry best practices for product inspection include:

- Establishing clear inspection criteria and specifications.

- Using appropriate inspection methods and equipment.

- Training inspectors to ensure proficiency and consistency.

- Conducting regular inspections as per established schedules.

- Documenting inspection results and maintaining accurate records.

- Implementing a continuous improvement process to enhance inspection efficiency and effectiveness.

7. How do you stay updated on new inspection techniques and technological advancements?

I stay updated on new inspection techniques and technological advancements by:

- Attending industry conferences, workshops, and trade shows.

- Reading technical journals and articles.

- Participating in professional development programs.

- Networking with peers and experts in the field.

8. What is your experience with failure analysis and root cause investigation?

In my previous role, I was responsible for conducting failure analysis and root cause investigations to identify and address product defects and quality issues. My approach involves:

- Thoroughly examining failed products to identify the cause of failure.

- Using analytical techniques, such as microscopy, spectroscopy, and stress analysis.

- Interviewing relevant personnel and reviewing manufacturing data.

- Developing and implementing corrective actions to prevent recurrence of failures.

9. How do you manage and prioritize multiple inspection tasks and projects?

To manage and prioritize multiple inspection tasks and projects effectively, I follow these principles:

- Prioritize tasks based on impact, deadlines, and resource availability.

- Use a task management system to track progress and stay organized.

- Communicate regularly with team members and stakeholders to coordinate efforts.

- Delegate tasks appropriately and provide guidance to team members.

- Review and adjust priorities as needed to ensure timely completion of critical tasks.

10. Describe a challenging product inspection scenario you faced and how you resolved it.

In a previous project, I encountered a complex product with multiple components and stringent quality requirements. The inspection process required a combination of manual and automated techniques. To resolve the challenge:

- I developed a detailed inspection plan and trained a team of inspectors.

- I implemented an automated inspection system to ensure accuracy and efficiency.

- I established a data collection and analysis system to identify trends and patterns.

- I worked closely with the production team to identify and address quality issues promptly.

- Through continuous improvement efforts, I optimized the inspection process, reducing inspection time and improving product quality.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Product Inspection Coordinator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Product Inspection Coordinator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Product Inspection Coordinator is responsible for ensuring that all products meet the company’s quality standards. This involves inspecting products at various stages of the production process, as well as developing and implementing quality control procedures.

1. Inspect products at various stages of the production process

The Product Inspection Coordinator will inspect products at various stages of the production process, including:

- Raw materials

- In-process products

- Final products

2. Develop and implement quality control procedures

The Product Inspection Coordinator will develop and implement quality control procedures to ensure that products meet the company’s standards. These procedures may include:

- Establishing inspection criteria

- Developing inspection methods

- Training inspectors

3. Maintain quality records

The Product Inspection Coordinator will maintain quality records to document the inspection process and track product quality. These records may include:

- Inspection reports

- Corrective action reports

4. Work with other departments to ensure product quality

The Product Inspection Coordinator will work with other departments, such as production, engineering, and sales, to ensure that product quality is maintained. This may involve:

- Providing feedback on product quality

- Participating in quality improvement initiatives

Interview Tips

Preparing for an interview for a Product Inspection Coordinator position can be daunting, but with the right preparation, you can increase your chances of success. Here are a few tips to help you prepare for your interview:

1. Research the company and the position

Before your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture, values, and goals, as well as the specific responsibilities of the position. You can find this information on the company’s website, in industry publications, or by talking to people who work for the company.

2. Practice answering common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice answering these questions in advance so that you can deliver your answers confidently and concisely.

3. Prepare questions to ask the interviewer

Asking questions at the end of an interview shows that you are interested in the position and that you have taken the time to prepare. It also gives you an opportunity to learn more about the company and the position. Some good questions to ask include: “What are the biggest challenges facing the company right now?” and “What are the opportunities for advancement within the company?”

4. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows the interviewer that you respect their time and that you are serious about the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Product Inspection Coordinator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!