Are you gearing up for an interview for a Water Pump Installer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Water Pump Installer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

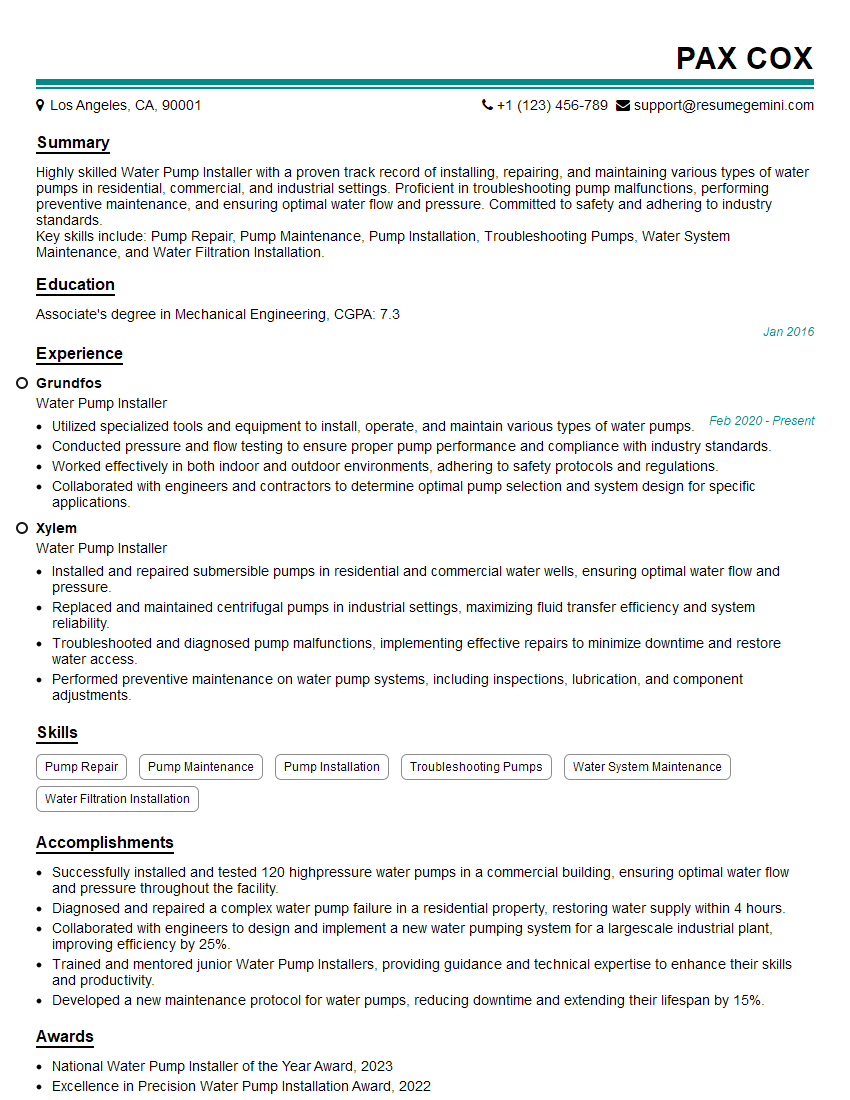

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Water Pump Installer

1. What are the key components of a water pump system and their functions?

- Pump: The heart of the system, responsible for moving water from the source to the destination.

- Motor: Powers the pump, converting electrical energy into mechanical energy.

- Piping: Carries water from the source to the pump and then to the destination.

- Valves: Control the flow of water through the system, allowing for isolation and adjustment.

- Reservoir: Stores water for use when the pump is not running, ensuring a steady supply.

2. How do you determine the appropriate size and type of water pump for a specific application?

Factors to consider

- Water source (depth, flow rate)

- Destination (height, distance)

- Required water flow rate and pressure

Pump types and their suitability

- Submersible: For deep wells, can be submerged in water.

- Jet: Uses a venturi effect to lift water, suitable for shallow wells.

- Centrifugal: Efficient for large flow rates over short distances.

3. Describe the process of installing a submersible water pump, including safety precautions.

- Prepare the well: Clean the well and ensure a secure connection for the pump.

- Install the pump: Lower the pump into the well and connect it to the power supply.

- Connect the piping: Use appropriate fittings and sealant to connect the pump to the piping.

- Test the system: Turn on the pump and check for leaks, proper flow rate, and pressure.

- Wear protective gear (gloves, safety glasses).

- Use proper lifting equipment to avoid injury.

- Follow electrical safety guidelines.

4. How do you troubleshoot a water pump that is not working properly?

- Check power supply: Ensure the pump is receiving power.

- Inspect the pump: Look for any visible damage or leaks.

- Test the impeller: Spin the impeller manually to check for obstructions or damage.

- Check the valves: Verify that valves are open and functioning properly.

- Measure water flow and pressure: Use a flow meter and pressure gauge to diagnose potential issues.

5. What are the different types of water pump maintenance and how often should they be performed?

- Regular maintenance:

- Check water levels and add water if necessary.

- Inspect for leaks and tighten connections.

- Clean the pump and filter (monthly or as needed).

- Seasonal maintenance:

- Winterize the pump if in a cold climate.

- Check for corrosion and replace any damaged parts.

- Annual maintenance:

- Disassemble the pump and inspect all components.

- Lubricate moving parts.

- Replace worn or damaged parts.

6. How do you calculate the efficiency of a water pump and what factors affect it?

Formula: Efficiency = (Actual Flow Rate / Theoretical Flow Rate) * 100% Factors affecting efficiency:- Pump design and construction

- Impeller size and configuration

- System head loss

- Water temperature

7. Can you explain the difference between centrifugal and positive displacement water pumps?

Centrifugal:- Uses centrifugal force to move water.

- Impeller spins, creating a high-pressure area at the periphery.

- Suitable for high flow rates and low pressures.

- Uses a piston or diaphragm to move water.

- Traps and displaces a fixed volume of water, creating high pressure.

- Suitable for low flow rates and high pressures.

8. What are the potential hazards associated with water pump installations and how can they be mitigated?

Hazards:- Electrical shock

- Water leaks

- Slips and falls

- Noise pollution

- Follow electrical codes and use proper grounding.

- Use leak-proof fittings and test for leaks.

- Wear slip-resistant shoes and work in a stable area.

- Install noise dampeners or barriers.

9. What are the latest advancements in water pump technology and how are they improving efficiency and performance?

- Variable speed drives: Adjust pump speed to match changing demand.

- Permanent magnet motors: Increase efficiency and reduce energy consumption.

- Advanced impeller designs: Optimize water flow and reduce cavitation.

- Smart control systems: Monitor and adjust pump operation based on real-time data.

10. Have you encountered any unique or challenging water pump installations in your previous experience? If so, how did you overcome them?

- Describe the specific installation challenge encountered.

- Explain the factors that contributed to the difficulty.

- Outline the steps taken to research and analyze the situation.

- Detail the technical solutions implemented to overcome the challenge.

- Discuss the results of the installation, including any performance improvements or customer satisfaction.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Water Pump Installer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Water Pump Installer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Water Pump Installers are responsible for installing, maintaining, and repairing water pumps in residential, commercial, and industrial buildings. They work closely with other tradespeople, such as plumbers and electricians, to ensure that the water pumps are properly installed and functioning correctly.

1. Install Water Pumps

Installers typically begin by determining the location of the water pump and then digging a hole for the pump. They then connect the pump to the water source and the electrical system. Once the pump is installed, they test it to make sure that it is working properly.

2. Maintain Water Pumps

In addition to installing water pumps, installers also perform maintenance on existing pumps. This includes tasks such as checking the pump’s oil level, replacing filters, and cleaning the pump housing. Installers also inspect the pump for any signs of damage or wear and tear.

3. Repair Water Pumps

When a water pump breaks down, installers are responsible for repairing it. This may involve replacing the pump’s motor, impeller, or other components. Installers also troubleshoot electrical problems and make sure that the pump is properly connected to the water source and the electrical system.

4. Other Responsibilities

In addition to the above responsibilities, water pump installers may also be responsible for:

- Providing customer service

- Estimating the cost of repairs

- Working with other tradespeople

- Keeping up with the latest industry trends

Interview Tips

Preparing for an interview can be daunting, but there are some things you can do to increase your chances of success. Here are a few tips for acing your water pump installer interview:

1. Research the Company

Before your interview, take some time to research the company. This will help you understand the company’s culture and values, as well as the specific requirements of the job. You can find information about the company on its website, social media pages, and Glassdoor.

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this job?”. It is helpful to practice answering these questions in advance so that you can deliver your answers confidently and concisely.

3. Be Prepared to Talk About Your Experience

The interviewer will want to know about your experience as a water pump installer. Be prepared to discuss your skills and experience in detail, and be sure to highlight any specific projects or accomplishments that you are proud of.

4. Ask Questions

Asking questions at the end of the interview shows that you are interested in the job and the company. It also gives you an opportunity to learn more about the position and the company’s culture. Some good questions to ask include:

- What are the biggest challenges facing the company right now?

- What is the company’s culture like?

- What are the opportunities for advancement within the company?

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Water Pump Installer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.