Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Propulsion Machinery Service Engineer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Propulsion Machinery Service Engineer so you can tailor your answers to impress potential employers.

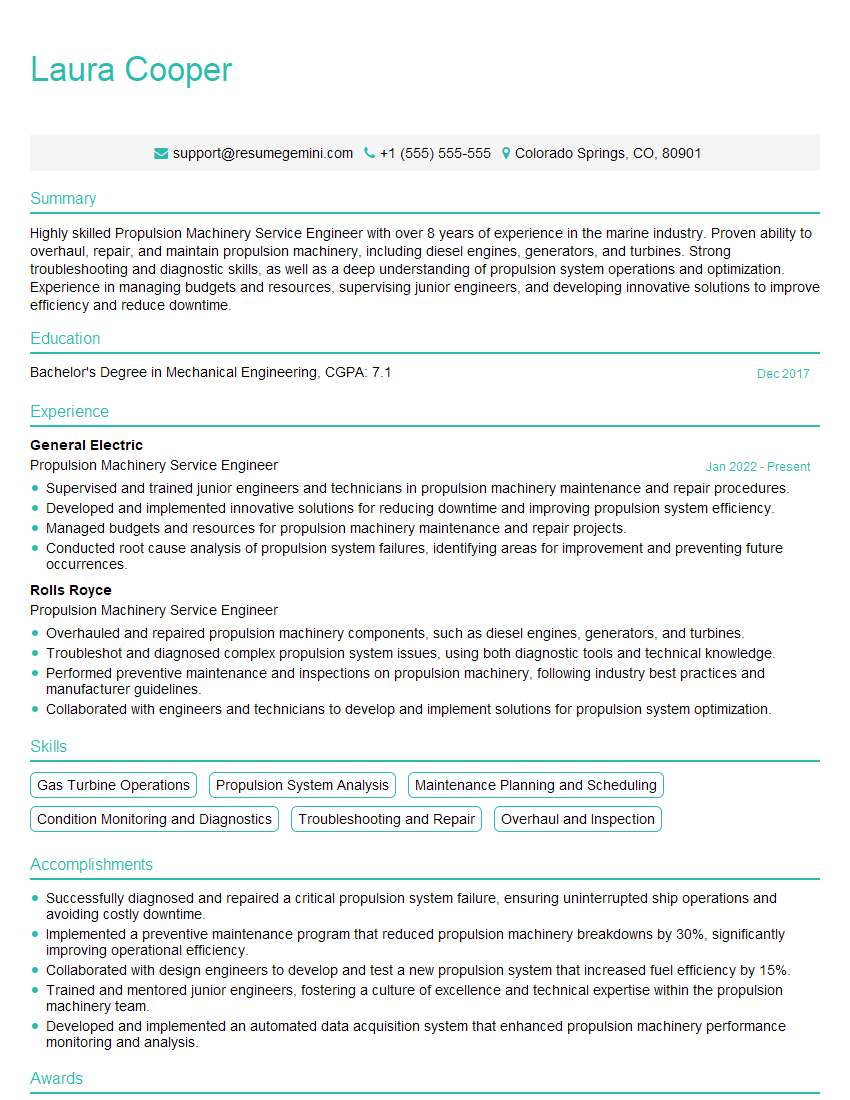

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Propulsion Machinery Service Engineer

1. What are the key considerations when selecting a propulsion machinery system for a marine vessel?

When selecting a propulsion machinery system for a marine vessel, key considerations include:

- Vessel type and purpose: Different vessel types (e.g., cargo, passenger, tanker) have specific propulsion requirements based on speed, range, and maneuverability.

- Fuel efficiency and emissions: Propulsion systems must meet regulatory standards and consider fuel consumption and environmental impact.

- Reliability and maintainability: The system should ensure uninterrupted operation, with easy access for maintenance and repairs.

- Space constraints: The engine room and machinery layout must accommodate the propulsion system efficiently.

- Cost and lifecycle value: Investment cost, operating expenses, and long-term performance should be carefully evaluated.

2. Explain the working principle of a marine diesel engine and its major components.

Engine Components

- Cylinder, piston, and crankshaft

- Fuel injection system

- Cooling system

- Lubrication system

- Exhaust system

Working Principle

- Intake Stroke: Air is drawn into the cylinder.

- Compression Stroke: Air is compressed in the cylinder.

- Power Stroke: Fuel is injected and ignited, creating pressure that drives the piston down, generating power.

- Exhaust Stroke: Combustion gases are expelled from the cylinder.

3. Describe the different types of marine propulsion systems and their advantages and disadvantages.

Types of Marine Propulsion Systems:

- Diesel Engines: Reliable, efficient, and widely used.

- Gas Turbines: High power-to-weight ratio, but less fuel-efficient.

- Electric Propulsion: Uses electric motors powered by batteries or generators, resulting in low noise and zero emissions.

- Hybrid Systems: Combine different propulsion systems for flexibility and efficiency.

Advantages and Disadvantages:

- Diesel Engines: Advantages: reliability, efficiency. Disadvantages: heavy, emissions.

- Gas Turbines: Advantages: high power, lightweight. Disadvantages: less fuel-efficient.

- Electric Propulsion: Advantages: low noise, zero emissions. Disadvantages: limited range, battery weight.

- Hybrid Systems: Advantages: flexibility, efficiency. Disadvantages: complexity, cost.

4. What are the techniques used to monitor and diagnose faults in propulsion machinery?

- Condition Monitoring Systems (CMS): Sensors monitor parameters such as vibration, temperature, pressure, and RPM.

- Data Analysis: Historical and real-time data is analyzed to identify trends and anomalies.

- Remote Diagnostics: Data is transmitted to shore-based experts for remote troubleshooting.

- Non-Destructive Testing (NDT): Techniques such as ultrasonic testing and infrared thermography can detect hidden defects.

- Oil and Fuel Analysis: Wear particles and contaminants in fluids indicate component health.

5. How do you ensure the safe and efficient operation of propulsion machinery while minimizing environmental impact?

- Regular Maintenance and Inspection: Adhere to manufacturer’s guidelines, and conduct periodic inspections and overhauls.

- Fuel Management: Optimize fuel quality, storage, and consumption to reduce emissions.

- Emissions Control Systems: Install and maintain scrubbers, selective catalytic reduction (SCR) systems, or hybrid technologies to minimize air pollution.

- Waste Management: Implement systems for responsible disposal of oily waste and other hazardous materials.

- Staff Training: Train crew on proper operation, maintenance, and emergency procedures.

6. Describe the role of a Propulsion Machinery Service Engineer in supporting marine operations.

- Provide technical expertise and guidance on propulsion machinery operation, maintenance, and repairs.

- Troubleshoot and diagnose faults, and recommend appropriate solutions.

- Oversee maintenance and overhaul activities to ensure machinery reliability.

- Monitor and analyze data from condition monitoring systems for predictive maintenance.

- Train crew members on safe and efficient operation practices.

7. What are the key performance indicators (KPIs) used to evaluate the effectiveness of propulsion machinery maintenance?

- Equipment Availability: Percentage of time the propulsion system is operational.

- Mean Time Between Failures (MTBF): Average time between breakdowns.

- Mean Time to Repair (MTTR): Average time to restore system functionality after a failure.

- Fuel Efficiency: Energy consumption per unit of power generated.

- Emissions Compliance: Adherence to environmental regulations.

8. Explain the role of Computerized Maintenance Management Systems (CMMS) in propulsion machinery maintenance.

- Centralizes maintenance records, work orders, and asset information.

- Automates maintenance scheduling, reminders, and notifications.

- Provides condition monitoring data and predictive maintenance capabilities.

- Improves communication and collaboration between maintenance teams.

- Tracks maintenance costs and inventory management.

9. Describe the challenges and opportunities in the field of propulsion machinery maintenance.

Challenges

- Complex and sophisticated machinery

- High safety and environmental standards

- Remote and demanding operating conditions

- Increasing use of automation and digital technologies

Opportunities

- Advancements in condition monitoring and predictive maintenance

- Development of more fuel-efficient and environmentally friendly technologies

- Increased use of data analytics for maintenance optimization

- Growing demand for skilled and experienced Propulsion Machinery Service Engineers

10. What is your approach to continuous improvement in propulsion machinery maintenance?

- Regularly monitor and analyze maintenance data to identify areas for improvement.

- Implement condition monitoring and predictive maintenance strategies.

- Invest in staff training and development.

- Collaborate with equipment manufacturers and industry experts.

- Stay informed about emerging technologies and best practices.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Propulsion Machinery Service Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Propulsion Machinery Service Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Propulsion Machinery Service Engineers are in charge of inspecting, maintaining, and repairing propulsion machinery on ships and marine vessels. They play a critical role in ensuring that these vessels can operate safely and efficiently.

1. Inspection and Troubleshooting

Inspect propulsion machinery and components for signs of wear, damage, or malfunction.

- Conduct diagnostic tests to identify the source of problems.

- Troubleshoot electrical, mechanical, and hydraulic systems.

2. Maintenance and Repair

Perform routine maintenance and repair tasks to keep propulsion systems operating smoothly.

- Overhaul or replace engines, turbines, propellers, and gearboxes.

- Repair or replace electrical and electronic components.

- Lubricate and adjust machinery to ensure optimal performance.

3. Installation and Commissioning

Install and commission new or overhauled propulsion systems.

- Supervise the installation process to ensure proper alignment and fit.

- Test and adjust systems to meet specifications.

- Train crew members on the operation and maintenance of new systems.

4. Safety and Compliance

Ensure that propulsion systems comply with safety regulations and industry standards.

- Conduct regular safety inspections.

- Implement safety protocols and procedures.

- Monitor and document safety data.

Interview Tips

Preparing for an interview for a Propulsion Machinery Service Engineer position requires in-depth knowledge of the field and a well-structured approach to answering interview questions.

1. Research the Company and Industry

Familiarize yourself with the company’s services, industry trends, and the specific requirements of the position.

2. Highlight Relevant Experience

Emphasize your experience and skills in propulsion machinery, including maintenance, repair, and troubleshooting. Quantify your accomplishments using specific examples.

3. Prepare for Technical Questions

Review fundamental concepts in marine propulsion, such as engine operation, hydraulic systems, and electrical components. Be prepared to discuss your understanding and practical experience.

4. Demonstrate Problem-Solving Abilities

Provide examples of how you have used your analytical skills to diagnose and resolve propulsion machinery issues.

5. Showcase Safety Awareness

Discuss your commitment to safety and your knowledge of safety regulations and procedures.

6. Ask Thoughtful Questions

Prepare insightful questions to ask the interviewer about the company, the role, and the industry. This demonstrates your genuine interest and engagement.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Propulsion Machinery Service Engineer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!