Are you gearing up for a career in Field Ironworker? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Field Ironworker and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

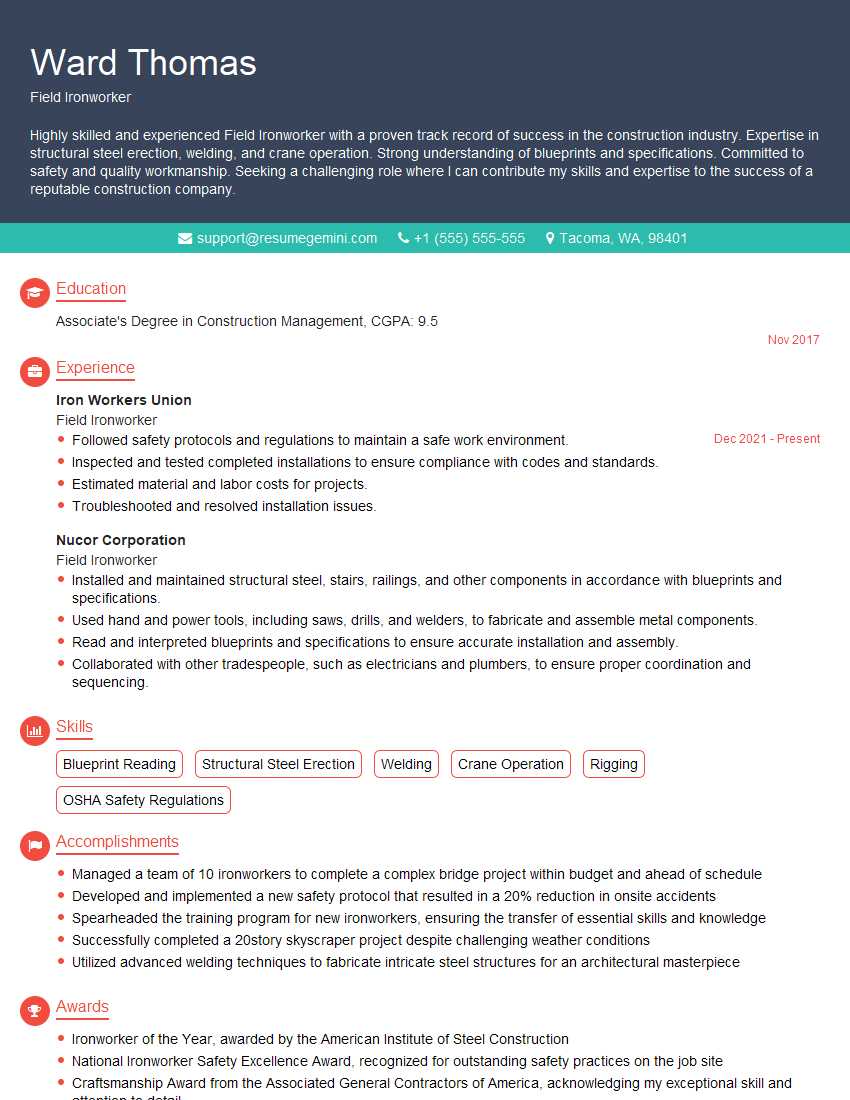

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Field Ironworker

Describe the process of installing a steel beam?

The process of installing a steel beam involves several steps:

- Planning and preparation: Determine the beam’s size, weight, and location. Gather necessary tools and equipment.

- Positioning the beam: Use a crane or other lifting device to lift the beam into place. Ensure proper alignment and support.

- Securing the beam: Weld or bolt the beam to supporting structures. Use appropriate connections and hardware.

- Leveling and adjusting: Adjust the beam’s position to ensure levelness and plumbness. Use shims or leveling compounds as needed.

- Finalizing installation: Tighten all connections, remove temporary supports, and inspect the installation for safety and stability.

What are the different types of welds used in ironworking?

Arc welding

- Shielded metal arc welding (SMAW)

- Gas metal arc welding (GMAW)

- Gas tungsten arc welding (GTAW)

- Flux-cored arc welding (FCAW)

Resistance welding

- Spot welding

- Projection welding

- Seam welding

Other welding techniques

- Oxy-fuel welding

- Forge welding

- Thermite welding

How do you ensure safety when working with heavy steel structures?

Ensuring safety in ironworking requires adherence to various safety protocols:

- Wear appropriate PPE: Hard hat, safety glasses, gloves, and protective clothing.

- Rig properly for lifting: Inspect lifting equipment, use appropriate slings and shackles, and signal clearly to crane operators.

- Follow load charts and capacity ratings: Avoid overloading equipment or exceeding weight limits.

- Secure work areas: Barricade areas, post warning signs, and control access to prevent unauthorized entry.

- Maintain worksite cleanliness: Clear tripping hazards, remove debris, and ensure adequate lighting.

- Stay alert and avoid distractions: Focus on the task at hand and communicate clearly with coworkers.

Describe the different bolts and fasteners used in ironworking?

Various bolts and fasteners are employed in ironworking, each with specific applications:

- Anchor bolts: Embed in concrete or masonry to secure structures.

- Carriage bolts: Have a round head and square neck for use with wood.

- Hex bolts: Have a hexagonal head and are commonly used with nuts and washers.

- Machine bolts: Precision-machined for use in machinery and equipment.

- Plow bolts: Used for securing metal sheets or plates.

- Self-drilling screws: Create their own threads as they are driven into metal.

How do you measure and cut steel accurately?

Accurate measurement and cutting techniques are crucial in ironworking:

- Measure twice, cut once: Use measuring tapes, levels, and squares to ensure precise measurements.

- Use appropriate cutting tools: Band saws, circular saws, and plasma cutters are used for different cutting tasks.

- Secure the steel properly: Clamp or fasten the steel to prevent movement during cutting.

- Follow cutting guidelines: Adhere to specified angles, lengths, and tolerances.

- Inspect cuts regularly: Check for squareness, smoothness, and accuracy to ensure proper fit.

How do you work effectively as part of a team?

Effective teamwork is essential in ironworking projects:

- Communication: Clearly convey information, instructions, and concerns to team members.

- Coordination: Plan and execute tasks collaboratively to avoid conflicts and ensure smooth workflow.

- Support: Provide assistance and support to team members when needed.

- Problem-solving: Work together to identify and resolve issues that arise during the project.

- Respect and appreciation: Acknowledge the contributions of team members and maintain a positive work environment.

Describe a time when you had to overcome a challenge on an ironworking project?

Discuss a specific situation where you faced a challenge and how you overcame it:

- Describe the challenge: Clearly state the nature of the problem you encountered.

- Explain your approach: Outline the steps you took to address the challenge.

- Highlight your skills: Emphasize the skills and knowledge you applied to solve the problem.

- Discuss the outcome: Explain how your actions resolved the challenge and contributed to the project’s success.

How do you stay updated with the latest advancements in ironworking techniques?

Discuss your methods for keeping up with industry advancements:

- Attend industry events: Participate in conferences, workshops, and trade shows to learn about new techniques and technologies.

- Read trade publications: Stay informed through industry magazines and journals.

- Online research: Utilize online resources, forums, and technical articles to expand your knowledge.

- Training and certification: Pursue professional development opportunities to enhance your skills and stay current with industry best practices.

- Network with other professionals: Connect with ironworkers, engineers, and architects to exchange knowledge and ideas.

What are the best practices for maintaining safety on an ironworking site?

Discuss key safety protocols and practices:

- Establish and enforce safety protocols: Implement clear guidelines for hazard identification, risk assessment, and accident prevention.

- Provide proper training and supervision: Ensure all workers receive comprehensive safety training and have adequate supervision.

- Use appropriate PPE: Require workers to wear appropriate personal protective equipment, including hard hats, safety glasses, gloves, and steel-toed boots.

- Regularly inspect equipment: Conduct regular inspections of lifting equipment, tools, and machinery to ensure they are in good working order.

- Maintain a clean and organized worksite: Keep work areas free of tripping hazards, clutter, and debris to prevent accidents.

- Promote a culture of safety: Foster a positive safety culture where workers actively participate in identifying and addressing hazards.

How do you ensure the accuracy and precision of your work?

Discuss your approach to maintaining accuracy and precision:

- Utilize precision tools and equipment: Use calibrated and well-maintained tools and equipment to ensure accurate measurements and cuts.

- Follow established standards and guidelines: Adhere to industry standards and project specifications to maintain consistency and accuracy.

- Conduct regular checks and inspections: Regularly check and inspect your work to identify and correct any errors or discrepancies.

- Seek feedback and verification: Request feedback from supervisors or colleagues to verify the accuracy and precision of your work.

- Pay attention to detail: Take pride in your work and pay meticulous attention to every detail to ensure the highest level of accuracy and precision.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Field Ironworker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Field Ironworker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Field Ironworkers are responsible for the safe and accurate installation of structural steel components on construction sites. Their key responsibilities include:

1. Structural Steel Installation

Installs structural steel beams, columns, and other components according to blueprints and specifications.

2. Rigging and Hoisting

Rigging and hoisting equipment to lift and position heavy steel components.

3. Welding and Cutting

Using welding and cutting equipment to join and fabricate steel components.

4. Blueprint Reading and Interpretation

Reading and interpreting blueprints and specifications to understand the design and installation requirements.

5. Material Handling

Handling and storing steel materials and components safely and efficiently.

6. Maintenance and Repair

Performing maintenance and repairs on steel structures and components.

7. Safety and Equipment Operation

Following safety procedures and operating equipment safely and efficiently.

Interview Tips

Preparing effectively for a Field Ironworker interview can increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Position

- Research the company and its projects to demonstrate your interest and knowledge.

- Review the job description thoroughly to identify the specific skills and qualifications required.

2. Highlight Relevant Skills and Experience

- Emphasize your skills in structural steel installation, rigging, hoisting, welding, and blueprint reading.

- Provide specific examples of projects where you have applied these skills successfully.

3. Showcase Safety Awareness

- Highlight your understanding of safety procedures and your commitment to working safely in a high-risk environment.

- Describe your experience with using safety equipment and following industry regulations.

4. Practice Answering Common Interview Questions

- Prepare for common interview questions related to your skills, experience, and safety practices.

- Use the STAR method (Situation, Task, Action, Result) to provide clear and concise answers.

5. Ask Thoughtful Questions

- Prepare questions to ask the interviewer about the company’s projects, safety protocols, and opportunities for professional development.

- Asking thoughtful questions shows your interest in the position and the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Field Ironworker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!