Are you gearing up for an interview for a Rebar Bender position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Rebar Bender and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

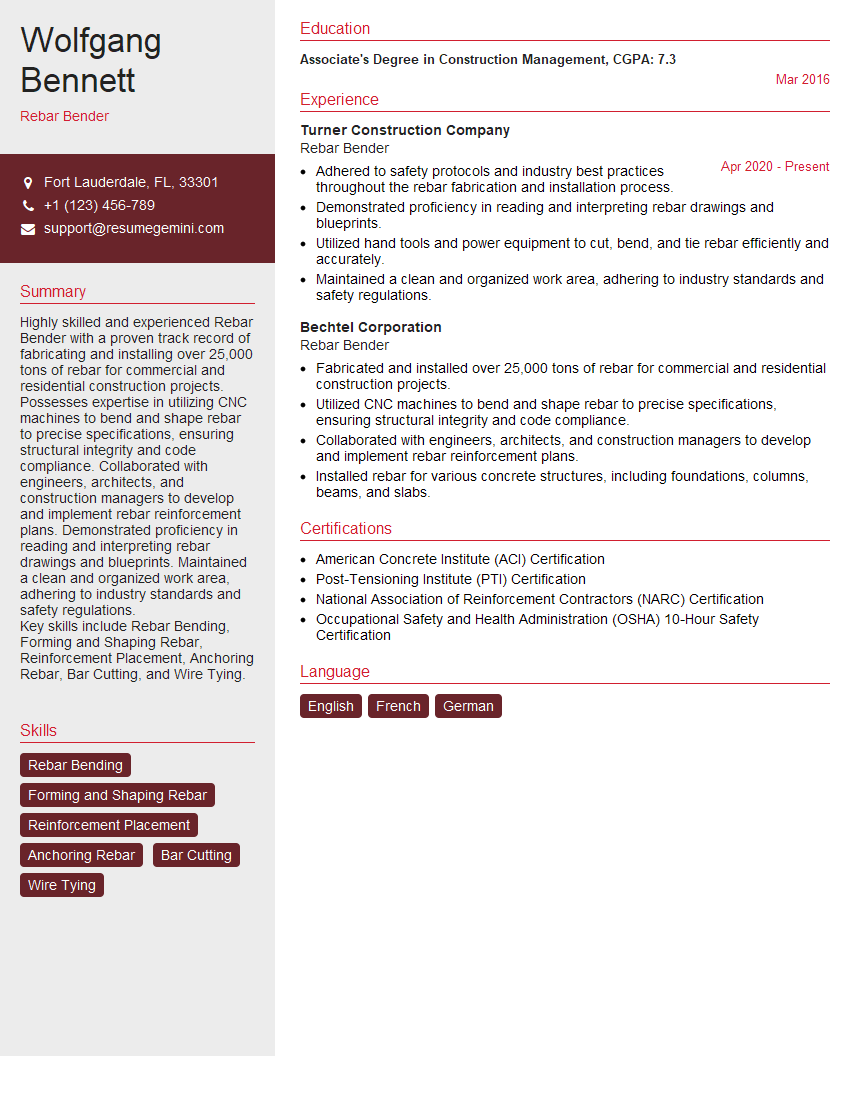

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Rebar Bender

1. What are the different types of rebar bending machines?

There are various types of rebar bending machines, including:

- Manual rebar benders: These machines require manual operation to bend rebar.

- Semi-automatic rebar benders: These machines offer semi-automated bending, simplifying the process.

- Fully automatic rebar benders: These advanced machines perform bending operations with minimal manual intervention.

2. How do you ensure accurate bending of rebar?

To ensure accurate bending, I:

- Check the machine’s calibration: Regular calibration is crucial for precise bending.

- Measure and mark the rebar: Proper measurement and marking guide accurate bending.

- Use appropriate bending dies: Selecting the correct dies for the desired shape and angle is essential.

- Bend the rebar in stages: Bending in stages prevents over-bending and ensures precision.

- Inspect the bent rebar: I carefully examine the bent rebar to ensure it meets specifications.

3. What factors affect the bending radius of rebar?

Factors influencing the bending radius include:

- Rebar diameter: Thicker rebar requires a larger bending radius.

- Rebar grade: Different grades of rebar have varying bending properties.

- Bending machine capacity: The machine’s maximum bending radius limits the bendability of rebar.

- Bending angle: Smaller bending angles allow for sharper bends and smaller radii.

4. What are the safety precautions to observe when operating a rebar bending machine?

Safety precautions are paramount:

- Wear appropriate safety gear: Gloves, safety glasses, and ear protection are essential.

- Secure the rebar properly: Properly positioned and secured rebar prevents accidents.

- Maintain a clean work area: Clear away any obstacles or debris to avoid tripping hazards.

- Never attempt repairs while the machine is running: Always shut down the machine before repairs or adjustments.

- Follow the manufacturer’s instructions: Adhering to operating guidelines ensures safe operation.

5. How do you troubleshoot common problems encountered during rebar bending?

Common troubleshooting steps include:

- Bent rebar is out of tolerance: Check machine calibration, rebar size, and bending angle.

- Rebar is cracking or breaking: Assess rebar grade, bending radius, and machine capacity.

- Machine is making excessive noise or vibrating: Inspect for loose bolts, worn gears, or lubrication issues.

- Bent rebar does not meet specifications: Examine bending dies, rebar placement, and machine settings.

- Machine is not operating smoothly: Check for power issues, hydraulic leaks, or pressure fluctuations.

6. How can you optimize rebar bending efficiency?

Optimization techniques include:

- Proper machine selection: Choosing a machine with the capacity and features suitable for the project.

- Efficient workflow: Planning the sequence of bends and organizing the rebar for smooth operation.

- Regular maintenance: Maintaining the machine keeps it running at optimal performance.

- Training and experience: Skilled operators can work faster and more accurately.

- Automation: Using semi-automatic or fully automatic machines can enhance efficiency.

7. What are the different types of rebar used in construction?

Common rebar types include:

- Plain rebar: Smooth surface rebar used for general reinforcement.

- Deformed rebar: Ribbed surface rebar that provides better bonding with concrete.

- Epoxy-coated rebar: Rebar with an epoxy coating for corrosion protection.

- Galvanized rebar: Zinc-coated rebar with enhanced corrosion resistance.

- Stainless steel rebar: Corrosion-resistant rebar used in aggressive environments.

8. What are the quality control measures implemented for rebar bending?

Quality control measures include:

- Visual inspection: Checking bent rebar for dimensional accuracy and any defects.

- Dimension verification: Measuring bent rebar to ensure conformity with specifications.

- Bend angle testing: Verifying the accuracy of bent angles using specialized equipment.

- Tensile strength testing: Assessing the strength of bent rebar to meet required standards.

- Documentation and traceability: Maintaining records of bending parameters and test results for traceability.

9. How do you handle complex rebar bending requirements?

Complex bending requirements can be addressed by:

- Using specialized bending dies: Dies designed for intricate shapes and angles.

- Multiple bending stages: Breaking down complex bends into smaller, manageable stages.

- Collaboration with design engineers: Consulting with engineers to determine the best approach.

- Trial and error: Experimenting with different bending methods to achieve desired results.

- Advanced bending machines: Using machines with sophisticated controls for precise and complex bending.

10. How do you stay up-to-date with the latest advancements in rebar bending technology?

To stay current, I:

- Attend industry conferences and workshops: Networking and learning about new technologies.

- Read trade publications and technical journals: Keeping informed about industry trends and best practices.

- Consult with manufacturers and suppliers: Seeking information about innovative products and techniques.

- Participate in online forums and discussions: Engaging with professionals and sharing knowledge.

- Undertake continuous education: Enhancing skills through courses and certifications.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Rebar Bender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Rebar Bender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Rebar Benders play a vital role in the construction industry by shaping and bending rebar, which forms the backbone of reinforced concrete structures. Their key job responsibilities include:

1. Bending and Shaping Rebar

This is the core responsibility of a Rebar Bender, involving the precise bending of rebar according to specified dimensions and shapes. They use specialized tools and machines, such as rebar bending machines, to create the required configurations.

- Following blueprints and specifications to accurately bend rebar

- Using bending machines and hand tools to achieve precise angles and shapes

2. Measuring and Cutting Rebar

Rebar Benders also measure and cut rebar to specific lengths to ensure accurate placement within concrete structures. They utilize measuring tapes, rebar cutters, and other tools to perform these tasks efficiently.

- Measuring and marking rebar for cutting

- Using rebar cutters or saws to cut rebar to the required lengths

3. Placing and Tying Rebar

In some instances, Rebar Benders may assist in placing and tying rebar within concrete forms. This involves positioning the rebar according to the structural design and securing it using wire or rebar ties.

- Positioning rebar within concrete forms based on blueprints

- Tying rebar together using wire or ties to ensure proper reinforcement

4. Equipment Maintenance and Calibration

Ensuring the proper functioning of bending machines and other equipment is crucial for Rebar Benders. They perform regular maintenance, such as cleaning, lubrication, and calibration to maintain optimal performance and accuracy.

- Performing routine maintenance and upkeep of rebar bending machines

- Calibrating machines to ensure precise bending angles

Interview Tips

To ace an interview for a Rebar Bender position, candidates should consider the following tips:

1. Highlight Relevant Skills and Experience

Emphasize your proficiency in rebar bending, measuring, cutting, and any other relevant skills. Showcase your experience with different types of rebar and bending machines. Quantify your accomplishments whenever possible, providing specific examples of your contributions.

- Quantify your experience in rebar bending, such as the number of tons of rebar bent per day or week.

- Provide examples of projects where you successfully bent rebar to complex specifications.

2. Demonstrate Knowledge of Industry Standards

Familiarity with industry standards and best practices is essential. Highlight your understanding of rebar grades, bending techniques, and safety protocols. Discuss your knowledge of the American Concrete Institute (ACI) standards or other relevant codes.

- Explain the different grades of rebar and their applications.

- Discuss the safety precautions that must be taken when bending rebar.

3. Showcase Physical Abilities and Attention to Detail

Rebar Bending requires physical strength and stamina. In the interview, highlight your ability to handle heavy rebar and work in physically demanding conditions. Additionally, emphasize your attention to detail and precision, as accurate bending is crucial.

- Describe your experience working with heavy materials and equipment.

- Provide examples of situations where you demonstrated attention to detail and accuracy.

4. Prepare for Common Interview Questions

Research common interview questions for Rebar Benders and prepare your answers in advance. Anticipate questions about your availability, willingness to work overtime, and experience with specific bending techniques. Practice your responses to ensure clarity and confidence.

- Prepare for questions about your availability to work overtime or on weekends.

- Practice answering questions about your experience with different types of rebar bending machines.

5. Dress Appropriately and Arrive Punctually

First impressions matter. Dress professionally for the interview and arrive on time to show respect for the interviewer and the company. Your attire and punctuality convey your professionalism and commitment to the role.

- Wear clean, pressed clothing that is appropriate for a construction environment.

- Plan your route in advance to avoid any potential delays.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Rebar Bender role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.