Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Foundry Metallurgist position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

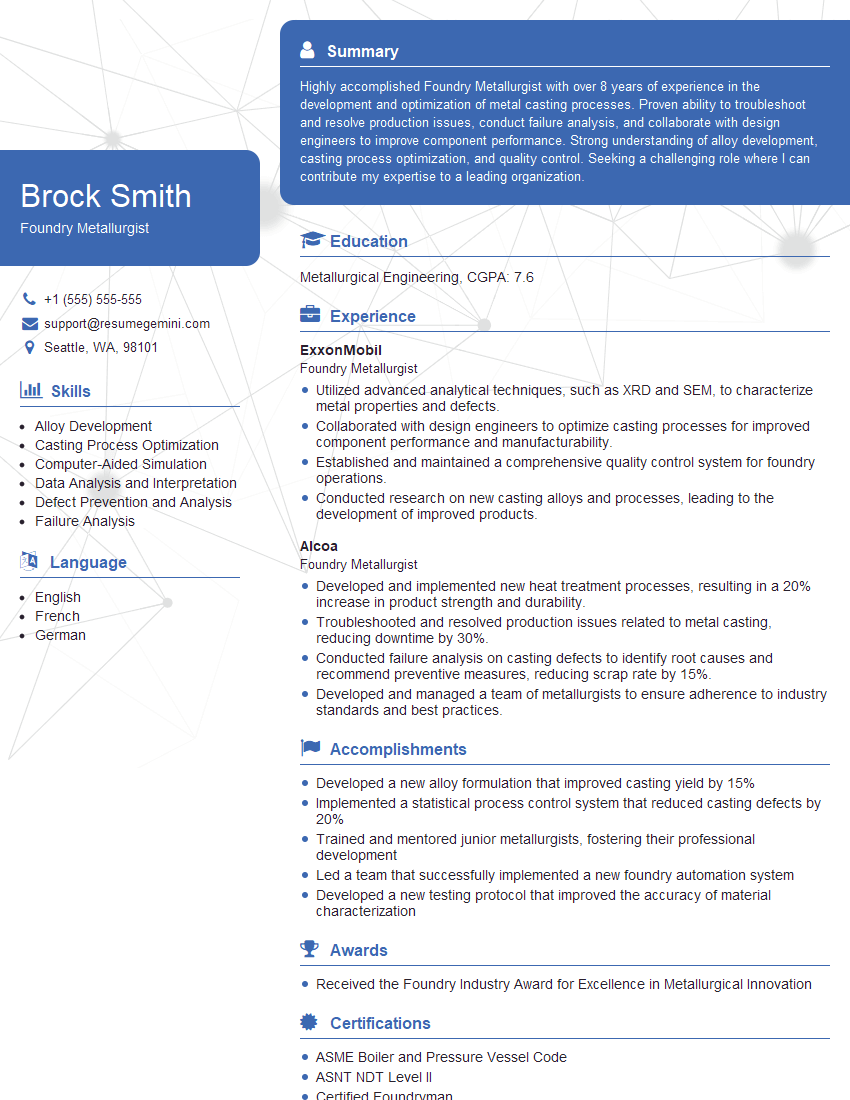

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Foundry Metallurgist

1. Explain the role of slag in the production of molten metal in a foundry?

The functions of slag in the production of molten metal in a foundry are:

- It protects the metal from oxidation and other harmful effects of the environment.

- It absorbs impurities from the molten metal.

- It controls the temperature of the molten metal.

- It helps to alloy the molten metal with other elements.

- It reduces the formation of defects in the final product.

2. What are the different types of sand used in foundry casting, and how do their properties affect the casting process?

Chemical composition

- Silica sand: SiO2, the most common type of sand used in foundries.

- Olivine sand: (Mg,Fe)2SiO4, a naturally occurring mineral that is more expensive than silica sand but has better thermal properties.

- Chromite sand: FeCr2O4, a manufactured sand that is used for high-temperature applications.

Grain size and shape

- Fine-grained sand produces castings with a smoother surface finish.

- Coarse-grained sand produces castings with a rougher surface finish but is more permeable, which allows gases to escape more easily during casting.

Binder

- Clay binders are the most common type of binder used in foundries.

- Organic binders, such as furan resins and phenolic resins, are also used.

3. Describe the various melting techniques used in the foundry industry?

The various melting techniques used in the foundry industry include:

- Cupola melting

- Induction melting

- Arc melting

- Vacuum melting

- Electroslag remelting

4. What are the different types of casting defects and their causes?

The different types of casting defects and their causes include:

- Shrinkage defects: Caused by the solidification of the molten metal and the resulting decrease in volume.

- Gas defects: Caused by the entrapment of gases in the molten metal.

- Inclusion defects: Caused by the presence of foreign particles in the molten metal.

- Mold defects: Caused by problems with the mold, such as cracks or shifts.

- Pattern defects: Caused by problems with the pattern, such as incorrect dimensions or surface finish.

5. What are the different types of heat treatment processes used in the foundry industry and their purpose?

The different types of heat treatment processes used in the foundry industry and their purpose include:

- Annealing: To soften the metal and improve its ductility.

- Normalizing: To refine the grain structure and improve the strength and toughness of the metal.

- Hardening: To increase the hardness and wear resistance of the metal.

- Tempering: To reduce the brittleness of the metal after hardening.

- Stress relieving: To remove residual stresses in the metal.

6. What are the different types of non-destructive testing methods used in the foundry industry?

The different types of non-destructive testing methods used in the foundry industry include:

- Radiography

- Ultrasonic testing

- Magnetic particle testing

- Penetrant testing

- Eddy current testing

7. What are the different types of ferrous and non-ferrous metals used in the foundry industry?

Ferrous metals

- Iron

- Steel

- Cast iron

Non-ferrous metals

- Aluminum

- Copper

- Zinc

- Magnesium

- Nickel

8. What are the different types of molding processes used in the foundry industry?

The different types of molding processes used in the foundry industry include:

- Sand casting

- Investment casting

- Die casting

- Centrifugal casting

- Permanent mold casting

- Shell molding

9. What are the different types of casting patterns used in the foundry industry?

The different types of casting patterns used in the foundry industry include:

- Wood patterns

- Metal patterns

- Plastic patterns

- Foam patterns

- Rapid prototyping patterns

10. What are the different types of core processes used in the foundry industry?

The different types of core processes used in the foundry industry include:

- Green sand cores

- Oil sand cores

- Shell cores

- Cold box cores

- Hot box cores

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Foundry Metallurgist.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Foundry Metallurgist‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Foundry Metallurgist is a specialist who applies metallurgical engineering principles in a foundry setting. They are responsible for developing and implementing processes that improve the quality and efficiency of metal castings, and for ensuring that the castings meet the required specifications.

1. Research and Development

Foundry Metallurgists conduct research and development to improve existing processes and develop new ones. They may also work on new alloys and casting techniques.

- Develop new casting processes to improve quality and efficiency.

- Conduct research on new alloys and casting techniques.

2. Process Improvement

Foundry Metallurgists are responsible for improving the efficiency and quality of casting processes. They may work on improving the design of casting molds, optimizing the melting and pouring processes, and developing new methods for controlling the cooling and solidification of castings.

- Improve the design of casting molds.

- Optimize the melting and pouring processes.

- Develop new methods for controlling the cooling and solidification of castings.

3. Quality Control

Foundry Metallurgists are responsible for ensuring that castings meet the required specifications. They may perform tests on castings to check their mechanical properties, chemical composition, and microstructure.

- Perform tests on castings to check their mechanical properties.

- Check the chemical composition of castings.

- Examine the microstructure of castings.

4. Troubleshooting

Foundry Metallurgists are responsible for troubleshooting problems that may occur during the casting process. They may work with other engineers and technicians to identify the cause of a problem and develop a solution.

- Identify the cause of problems that occur during the casting process.

- Develop solutions to problems that occur during the casting process.

Interview Tips

Preparing for a Foundry Metallurgist interview can be daunting, but with the right preparation, you can increase your chances of success. Here are a few tips to help you ace your interview:

1. Research the Company and the Position

Before your interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture, goals, and the specific requirements of the job. You can find information about the company on their website, LinkedIn, and other online sources.

- Visit the company’s website to learn about their history, mission, and values.

- Read the job description carefully to identify the key requirements of the position.

- Check the company’s LinkedIn page to see what employees are saying about the company and the work environment.

2. Prepare Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked in a Foundry Metallurgist interview. It is important to prepare your answers to these questions in advance so that you can deliver them confidently and concisely.

- Tell me about your experience with foundry metallurgy.

- What are your strengths and weaknesses as a Foundry Metallurgist?

- Why are you interested in working for our company?

3. Bring Samples of Your Work

If you have any samples of your work that you can bring to your interview, do so. This could include technical reports, research papers, or presentations that you have given. Bringing samples of your work will give the interviewer a chance to see your skills and abilities firsthand.

- Bring copies of technical reports or research papers that you have written.

- Bring presentations that you have given on foundry metallurgy topics.

- Bring examples of your work that demonstrate your problem-solving skills.

4. Be Prepared to Ask Questions

At the end of your interview, the interviewer will likely ask if you have any questions. This is your opportunity to learn more about the company, the position, and the work environment. It is important to prepare a few questions in advance so that you can show the interviewer that you are engaged and interested in the position.

- Ask about the company’s plans for future growth and development.

- Ask about the specific challenges that the company is facing and how you can help to address them.

- Ask about the company’s culture and work environment.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Foundry Metallurgist, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Foundry Metallurgist positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.