Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Duralumin Mechanic position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

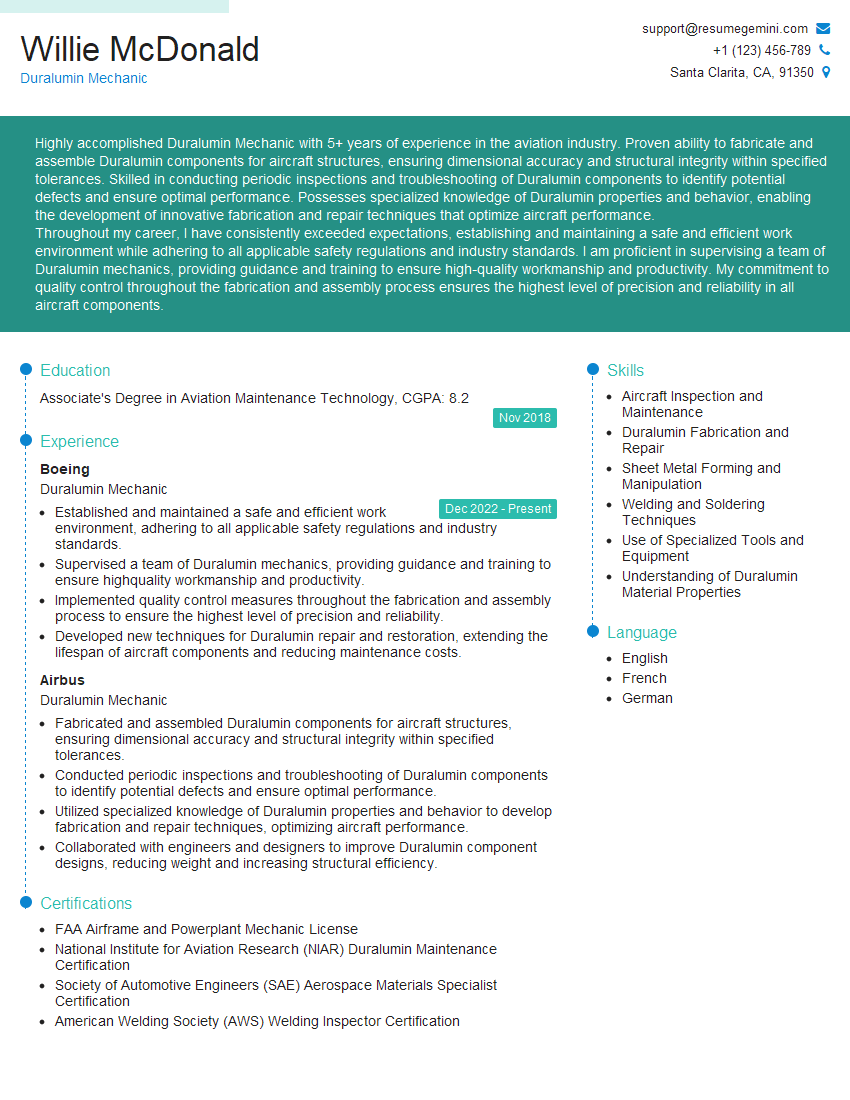

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Duralumin Mechanic

1. Describe the essential properties and characteristics of duralumin?

Here are some of the essential properties and characteristics of duralumin:

- Duralumin is a high-strength alloy of aluminum, copper, magnesium, and manganese.

- It is known for its high strength-to-weight ratio, making it a suitable material for aerospace applications.

- Duralumin is also corrosion-resistant and has good weldability.

2. Explain the process of heat treating duralumin?

Heat treating duralumin involves several steps to enhance its mechanical properties:

- Solution heat treatment: The alloy is heated to a high temperature (typically around 495°C) and held for a specific duration to dissolve alloying elements into the aluminum matrix.

- Quenching: The heated alloy is rapidly cooled, usually by submerging it in water or oil, to trap the alloying elements in a supersaturated solid solution, resulting in a soft and ductile material.

- Aging: The quenched alloy is then subjected to aging at a lower temperature (around 190°C) for a specific time, allowing the alloying elements to precipitate out of the supersaturated solid solution, which strengthens the material.

3. What are the common applications of duralumin?

- Aerospace industry: Duralumin is widely used in aircraft structures, including wings, fuselages, and landing gear, due to its high strength-to-weight ratio.

- Automotive industry: Duralumin is used in the production of high-performance vehicles and racing cars, where lightweight and strength are essential.

- Marine industry: Duralumin is employed in shipbuilding, particularly for high-speed boats and yachts, as it offers both strength and corrosion resistance.

- Sports equipment: Duralumin is utilized in the manufacturing of sports equipment, such as bicycle frames and ski poles, where strength and weight reduction are important.

4. How do you ensure the quality of duralumin during fabrication?

To ensure the quality of duralumin during fabrication, several measures can be taken:

- Material testing: Conduct mechanical tests, such as tensile and hardness tests, to verify that the duralumin meets the required specifications.

- Visual inspection: Examine the duralumin for any surface defects, cracks, or other imperfections that could compromise its integrity.

- Non-destructive testing: Employ non-destructive testing methods, such as ultrasonic testing or radiography, to detect internal flaws or defects.

- Process control: Adhere to established fabrication procedures, including proper heat treatment and aging processes, to ensure consistent material properties.

5. Describe the challenges faced when working with duralumin?

- Formability: Duralumin can be difficult to form or bend due to its high strength, requiring specialized forming techniques and tooling.

- Corrosion susceptibility: While duralumin has good corrosion resistance, it can be susceptible to stress corrosion cracking, especially in marine environments.

- High cost: Duralumin is a relatively expensive material compared to other aluminum alloys, which can be a factor in project budgeting.

- Limited weldability: Welding duralumin requires careful control of heat input and proper filler materials to avoid compromising the material’s strength.

6. How do you mitigate the risks associated with machining duralumin?

- Use sharp cutting tools: Employ sharp cutting tools to minimize burr formation and ensure clean cuts.

- Apply proper lubrication: Utilize appropriate cutting fluids or lubricants to reduce friction and heat generation during machining.

- Control cutting parameters: Optimize cutting speeds, feeds, and depths of cut to prevent excessive tool wear and workpiece damage.

- Employ proper chip removal: Ensure efficient chip removal to prevent chip buildup and potential workpiece damage.

- Regularly inspect tools and workpiece: Monitor cutting tools for wear and the workpiece for any irregularities to address issues promptly.

7. Explain the importance of surface preparation for duralumin bonding?

Surface preparation is crucial for successful duralumin bonding as it ensures a clean and contaminant-free surface for proper adhesive adhesion:

- Cleaning: Thoroughly clean the duralumin surface using solvents or detergents to remove dirt, grease, and other contaminants.

- Abrading: Lightly abrade the surface using fine sandpaper or abrasive pads to create a slightly roughened texture, increasing the surface area for adhesive bonding.

- Degreasing: Apply a degreasing agent to remove any remaining oils or residues that could interfere with adhesive bonding.

8. How do you select the appropriate adhesive for duralumin bonding?

Selecting the right adhesive for duralumin bonding depends on several factors:

- Bond strength: Consider the required bond strength for the specific application.

- Environmental conditions: Choose an adhesive that can withstand the expected operating conditions, including temperature, humidity, and exposure to chemicals.

- Material compatibility: Ensure the adhesive is compatible with duralumin and does not cause any adverse reactions.

- Viscosity and application method: Select an adhesive with the appropriate viscosity and application method for the specific bonding process.

9. Describe the process of adhesive bonding for duralumin?

The general process of adhesive bonding for duralumin involves:

- Surface preparation: Clean, abrade, and degrease the duralumin surfaces to ensure proper bonding.

- Adhesive application: Apply the adhesive to one or both surfaces, depending on the adhesive type and bonding method.

- Assembly: Join the duralumin surfaces and apply pressure or clamping to maintain contact during curing.

- Curing: Allow the adhesive to cure according to the manufacturer’s instructions, which may involve heat or pressure.

- Inspection: Inspect the bonded joint for proper adhesion and strength.

10. What are the common defects that can occur during duralumin bonding, and how can they be prevented?

- Insufficient surface preparation: Improper surface preparation can lead to poor adhesive bonding. Ensure thorough cleaning, abrasion, and degreasing.

- Inadequate adhesive selection: Choosing an unsuitable adhesive can result in weak or failing bonds. Carefully consider bond strength, environmental conditions, and material compatibility.

- Incorrect application: Improper adhesive application, such as uneven distribution or insufficient thickness, can compromise the bond strength. Follow the manufacturer’s instructions for proper application.

- Insufficient curing: Incomplete or improper curing can prevent the adhesive from reaching its full strength. Adhere to the recommended curing time and conditions.

- Environmental factors: Exposure to extreme temperatures, humidity, or chemicals can affect the bond strength. Ensure the adhesive is compatible with the expected operating conditions.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Duralumin Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Duralumin Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Duralumin Mechanic, you will play a vital role in the maintenance and repair of aircrafts, using specialized knowledge of duralumin, a high-strength aluminum alloy commonly used in aircraft construction.

1. Duralumin Fabrication and Repair

You will be responsible for fabricating and repairing duralumin components, ensuring they meet strict specifications and industry standards. This includes shaping, forming, and welding duralumin using specialized techniques.

2. Aircraft Maintenance and Inspection

You will conduct routine maintenance and inspections of aircraft structures, focusing on areas where duralumin is used. You will identify potential issues, such as corrosion or damage, and recommend appropriate repairs.

3. Quality Control

You will perform quality control checks on duralumin components and repairs, ensuring they adhere to established standards and specifications. This includes testing the strength and durability of materials and workmanship.

4. Collaboration and Communication

You will work closely with other mechanics, engineers, and inspectors to ensure seamless aircraft maintenance operations. You will effectively communicate technical information and findings to colleagues and supervisors.

Interview Tips

To ace your interview for a Duralumin Mechanic position, here are some essential tips to follow:

1. Research the Company and Position

Familiarize yourself with the company’s products, services, and industry reputation. Research the specific requirements of the Duralumin Mechanic role and identify how your skills and experience align with the job description.

2. Highlight Your Technical Expertise

Showcase your in-depth knowledge of duralumin metallurgy, fabrication, and repair techniques. Provide specific examples of projects where you successfully worked with duralumin and adhered to industry standards.

3. Emphasize Your Attention to Detail

Stress your meticulous nature and ability to identify and rectify even the smallest defects in duralumin components. Provide instances where your keen eye for detail contributed to successful aircraft maintenance operations.

4. Demonstrate Your Communication Skills

Highlight your ability to effectively communicate technical information to both technical and non-technical audiences. Give examples of how you have successfully collaborated with engineers, inspectors, and other stakeholders.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Duralumin Mechanic role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.