Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Extrusion Former position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

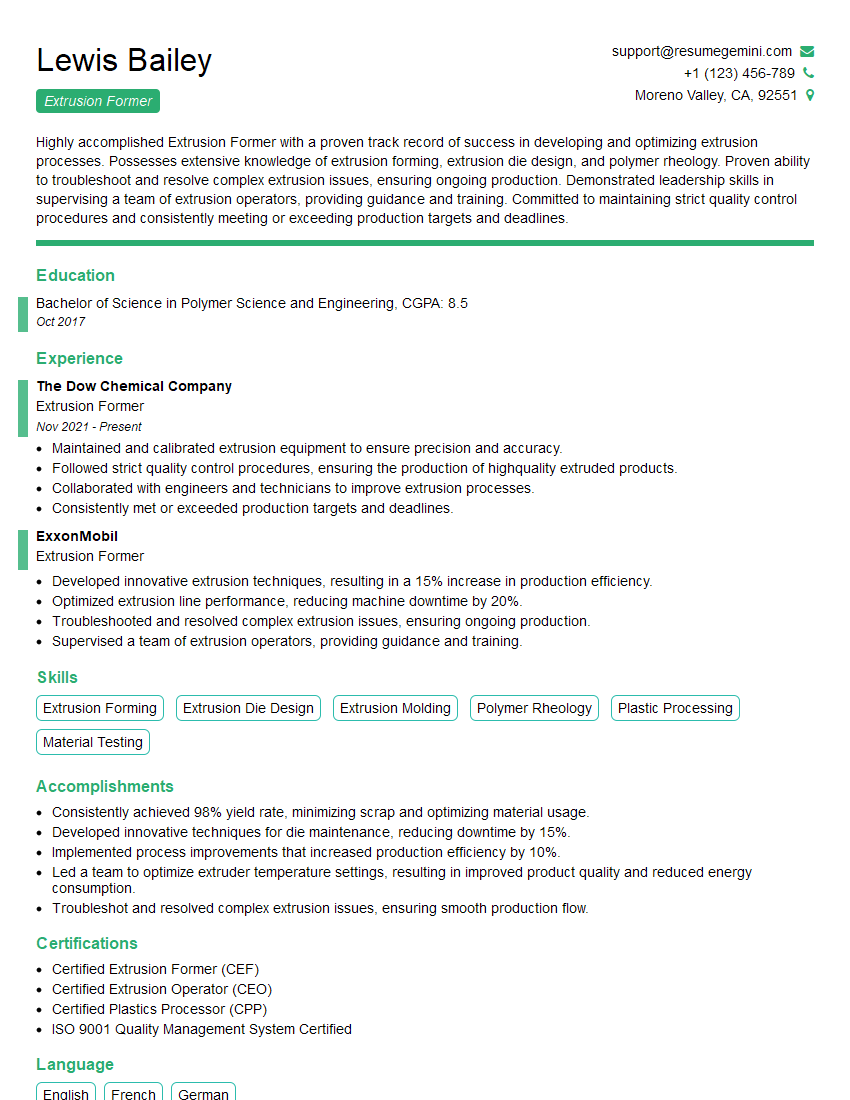

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Extrusion Former

1. What are the key responsibilities of an Extrusion Former?

- Set up and operate extrusion forming machines to produce plastic and rubber products.

- Monitor production processes to ensure quality and efficiency.

- Troubleshoot and resolve equipment issues.

- Perform routine maintenance on equipment.

- Adhere to safety protocols and regulations.

2. What are the different types of extrusion forming processes?

- Blown film extrusion: Produces thin plastic film for packaging and other applications.

- Cast film extrusion: Produces thicker plastic film for applications such as window glazing and agricultural mulch.

- Pipe extrusion: Produces plastic pipes for water, gas, and drainage systems.

- Profile extrusion: Produces plastic shapes for applications such as window frames, decking, and siding.

3. What are the key factors that affect the quality of extruded products?

- Material properties: The type of plastic or rubber used will affect the strength, flexibility, and other properties of the finished product.

- Extrusion process parameters: Factors such as temperature, pressure, and speed will affect the quality of the extruded product.

- Equipment condition: Worn or malfunctioning equipment can produce defective products.

4. How do you troubleshoot common extrusion forming problems?

- Product defects: Check for problems with the material, extrusion process parameters, or equipment.

- Equipment malfunctions: Inspect the equipment for worn or damaged parts, and check for electrical or mechanical problems.

- Process inefficiencies: Analyze the extrusion process to identify areas where improvements can be made to increase efficiency and reduce waste.

5. What are the safety precautions that must be followed when operating extrusion forming machines?

- Wear appropriate safety gear: This includes safety glasses, gloves, and hearing protection.

- Be aware of moving parts: Keep hands and loose clothing away from moving machinery.

- Follow proper operating procedures: Use the equipment as intended and avoid making unauthorized modifications.

- Report any safety concerns: Immediately report any unsafe conditions or equipment malfunctions to a supervisor.

6. What are your strengths as an Extrusion Former?

- Attention to detail: I am able to identify and resolve quality issues quickly.

- Problem-solving skills: I can troubleshoot equipment problems and develop solutions to improve efficiency.

- Commitment to safety: I am committed to following all safety protocols and ensuring a safe working environment.

- Experience with different extrusion processes: I have experience with a variety of extrusion forming processes, including blown film extrusion, cast film extrusion, pipe extrusion, and profile extrusion.

7. What are your career goals?

- Advance my skills and knowledge: I am eager to learn new extrusion forming techniques and expand my knowledge of the industry.

- Take on leadership roles: I am interested in opportunities to lead and mentor other extrusion formers.

- Contribute to the success of the company: I am committed to helping the company achieve its goals and objectives.

8. Why are you interested in working for our company?

- Your company’s reputation: I have heard great things about your company’s commitment to quality and innovation.

- Your company’s products: I am impressed with the range and quality of your company’s products.

- Your company’s growth opportunities: I believe that your company provides a great opportunity for me to grow my skills and advance my career.

9. Do you have any questions for me?

This is an opportunity for you to ask questions about the position, the company, or the industry. Asking thoughtful questions shows that you are engaged and interested in the opportunity.

10. How can you contribute to our company’s success?

- Use my skills and experience: I can use my skills and experience in extrusion forming to help the company produce high-quality products and improve efficiency.

- Be a team player: I am a team player and I am committed to working with others to achieve the company’s goals.

- Contribute to the company’s culture: I am a positive and enthusiastic person and I believe that I can contribute to the company’s positive culture.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Extrusion Former.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Extrusion Former‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Extrusion Former is responsible for operating extrusion machines to form plastic, rubber, or metal products. They work in a variety of industries, including manufacturing, construction, and packaging. The day-to-day responsibilities of an Extrusion Former may include the following:

1. Machine Setup and Operation

An Extrusion Former must be able to set up and operate extrusion machines. They must be able to follow the instructions of their supervisors, and ensure that the machine is running properly.

- Set up and operate extrusion machines to form plastic, rubber, or metal products.

- Monitor the operation of the machine, and make adjustments as needed.

2. Product Quality Control

Extrusion Formers are responsible for ensuring that the products they produce meet the specifications of their customers. They must be able to inspect the products for any defects, and make corrections as needed.

- Inspect the products for any defects, and make corrections as needed.

- Ensure that the products meet the specifications of the customers.

3. Maintenance and Repair

Extrusion Formers must be able to perform basic maintenance and repair on their machines. They must be able to troubleshoot problems, and replace parts as needed.

- Perform basic maintenance and repair on extrusion machines.

- Troubleshoot problems, and replace parts as needed.

4. Safety Compliance

Extrusion Formers must be able to follow safety procedures, and wear protective gear. They must be able to work in a safe manner, and avoid accidents.

- Follow safety procedures, and wear protective gear.

- Work in a safe manner, and avoid accidents.

Interview Tips

To help you prepare for your interview, here are a few tips:

1. Research the Company and the Position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you understand what the company is looking for in a candidate, and it will also help you to answer questions about the company and the position.

- Visit the company’s website.

- Read the job description carefully.

- Talk to people who work for the company, if possible.

2. Practice Your Answers to Common Interview Questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. Take some time to practice your answers to these questions so that you can deliver them confidently and clearly.

- Make a list of common interview questions.

- Write out your answers to these questions.

- Practice your answers out loud.

3. Dress Professionally and Arrive on Time

Your appearance and punctuality will make a big impression on the interviewer. Dress professionally and arrive on time for your interview. This will show the interviewer that you are serious about the position and that you respect their time.

- Dress in a suit or business casual attire.

- Be punctual for your interview.

- Make eye contact and greet the interviewer with a firm handshake.

4. Be Yourself

The most important thing is to be yourself during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Be honest and authentic, and let your personality shine through.

- Be honest about your skills and experience.

- Be confident in your abilities.

- Be yourself and let your personality shine through.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Extrusion Former role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.