Feeling lost in a sea of interview questions? Landed that dream interview for Hood Maker but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Hood Maker interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

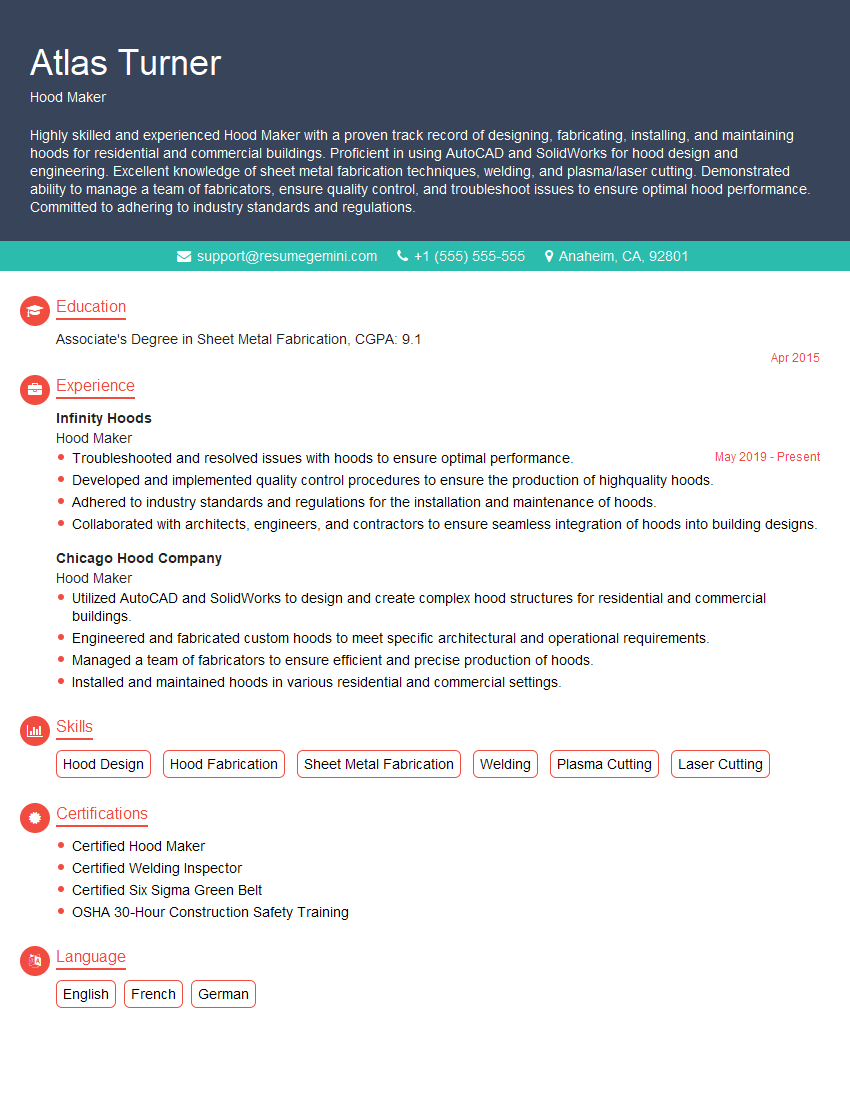

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Hood Maker

1. What are the different types of hoods and their uses?

There are various types of hoods, each designed for specific purposes:

- Type 1 Hoods: Used in laboratories and other environments where hazardous chemicals are handled. They provide maximum containment and exhaust fumes and gases.

- Type 2 Hoods: Designed for use in educational and research settings where chemical vapors and fumes are less hazardous. They provide less containment than Type 1 hoods.

- Perchloric Acid Hoods: Specialized hoods used to handle highly corrosive perchloric acid. They incorporate special materials and features to minimize the risk of explosions.

- Biosafety Cabinets: Used in biological laboratories to protect personnel and the environment from exposure to infectious agents. They provide inward airflow to prevent contamination.

- Laminar Flow Hoods: Used in cleanrooms and other controlled environments to provide a sterile and particle-free workspace. They maintain a constant unidirectional airflow.

2. What materials are commonly used in hood fabrication, and what are their advantages and disadvantages?

Metals

- Stainless Steel: Durable, corrosion-resistant, and easy to clean. However, it can be expensive and may not be suitable for highly acidic or alkaline environments.

- Galvanized Steel: Affordable and corrosion-resistant, but less durable than stainless steel.

- Aluminum: Lightweight, corrosion-resistant, and easy to fabricate. However, it may not be suitable for high-temperature applications.

Plastics

- Polypropylene (PP): Chemical-resistant, durable, and lightweight. However, it may not be suitable for high-temperature applications.

- Polyethylene (PE): Chemical-resistant and flexible. However, it may not be as durable as other materials.

- Polyvinyl Chloride (PVC): Flame-retardant and resistant to many chemicals. However, it may release toxic fumes when burned.

Composite Materials

- Fiberglass-Reinforced Plastic (FRP): Durable, corrosion-resistant, and lightweight. However, it may be more expensive than other materials.

3. What factors should be considered when designing a hood exhaust system?

- Airflow Rate: Sufficient airflow must be provided to capture and exhaust contaminants.

- Hood Type: The type of hood (e.g., Type 1, Type 2) determines the required airflow rate and containment level.

- Exhaust Ductwork: Proper ductwork design ensures efficient airflow and minimizes pressure drop.

- Fan Selection: The fan must be sized appropriately to provide the required airflow rate and overcome system resistance.

- Noise Control: Measures should be taken to reduce noise generated by the exhaust system.

- Energy Efficiency: Energy-efficient fans and ductwork should be considered to minimize operating costs.

4. What are the safety regulations and standards that apply to hood fabrication and installation?

- OSHA: Occupational Safety and Health Administration regulations (e.g., 29 CFR 1910.1450) cover ventilation systems, including hoods.

- ANSI: American National Standards Institute publishes standards for laboratory fume hoods (e.g., ANSI Z9.5).

- ASHRAE: American Society of Heating, Refrigerating and Air-Conditioning Engineers sets standards for ventilation and exhaust systems (e.g., ASHRAE 110).

- NFPA: National Fire Protection Association provides codes and standards for fire safety, including ventilation systems (e.g., NFPA 91).

5. How do you ensure that a hood system meets the performance requirements specified in the design?

- Design Review: Review design plans to ensure they align with specifications.

- Material Selection: Choose materials that meet the required corrosion resistance, durability, and performance standards.

- Fabrication Quality Control: Implement quality control measures during fabrication to ensure accuracy and compliance with specifications.

- Installation Inspection: Inspect the installed system to verify proper alignment, sealing, and airflow.

- Performance Testing: Conduct performance testing (e.g., air velocity measurements) to verify that the system meets the design requirements.

6. What maintenance and inspection procedures are recommended for hood systems?

- Regular Inspections: Conduct visual inspections to check for damage, leaks, or blockages.

- Filter Replacement: Replace filters regularly to maintain airflow and prevent contamination.

- Performance Testing: Perform periodic performance testing to verify airflow rates and containment levels.

- Cleaning and Decontamination: Clean and decontaminate hoods as necessary to maintain hygiene and remove harmful substances.

7. What troubleshooting steps would you take if a hood system is not performing as expected?

- Inspect Airflow: Check airflow rates and ensure they meet specifications.

- Examine Filters: Inspect filters for blockages or damage.

- Check Ductwork: Inspect ductwork for leaks, blockages, or damage.

- Examine Fan: Check fan operation and performance.

- Verify Electrical Connections: Ensure proper electrical connections throughout the system.

8. How do you stay up-to-date on the latest industry best practices and technological advancements in hood fabrication?

- Attend Conferences and Workshops: Participate in industry events to learn about new technologies and regulations.

- Read Industry Publications: Stay informed through industry magazines, journals, and online resources.

- Collaborate with Experts: Network with other professionals and consult with experts to exchange knowledge.

- Continuing Education: Engage in professional development programs to enhance skills and stay abreast of industry trends.

9. What sets you apart as a qualified hood maker, and why should we choose you for this position?

With my comprehensive knowledge of hood fabrication techniques, industry standards, and safety regulations, I am confident in my ability to deliver high-quality hoods that meet your specific requirements. My experience in designing, fabricating, and installing hood systems for various industries, including healthcare, education, and research, has equipped me with the skills and expertise to excel in this role.

Furthermore, I am committed to staying up-to-date on the latest industry best practices and technological advancements. This allows me to consistently produce efficient and effective hood systems that meet the evolving needs of our clients. I am also a highly motivated and detail-oriented individual, with a strong work ethic and a commitment to delivering exceptional results.

10. What are your salary expectations for this position?

My salary expectations are commensurate with my experience, skills, and the responsibilities of this role. I am open to discussing a competitive salary package that is aligned with the industry standards and the value I can bring to your organization. I am also interested in learning about the company’s benefits and compensation structure.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Hood Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Hood Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Hood Maker is responsible for manufacturing, installing, and servicing hoods and ventilation systems primarily in commercial kitchens. They ensure that hoods meet safety and performance standards, including proper ventilation, filtration, and grease removal.

1. Fabrication and Installation

fabricate and assemble hoods and ventilation systems according to blueprints and specifications

- Measure, cut, and weld metal components using specialized tools and equipment.

- Follow building codes and safety regulations to ensure the proper installation of systems.

2. Maintenance and Repair

Diagnose and repair malfunctions in ventilation systems

- Inspect and clean hoods and filters to maintain optimal performance.

- Troubleshoot and resolve issues with fans, motors, and other components.

3. Customer Service

Provide excellent customer service and support

- Respond promptly to customer inquiries and complaints.

- Conduct regular maintenance inspections and provide recommendations.

4. Safety and Compliance

Adhere to safety protocols and industry regulations

- Wear appropriate safety gear and follow established safety procedures.

- Ensure that hoods and ventilation systems meet all applicable codes and standards.

Interview Tips

Preparing for an interview as a Hood Maker requires thorough research and practice. Here are a few tips to help you ace it:

1. Research the Company and Industry

Gain insights into the company’s values, mission, and recent projects to demonstrate your interest and knowledge.

- Visit the company website and read about their services, products, and culture.

- Explore industry publications and news articles to stay updated on trends and challenges.

2. Highlight Your Technical Skills

Emphasize your proficiency in fabrication techniques, welding, and electrical work. Provide specific examples of projects you have completed.

- Quantify your accomplishments using metrics, such as the number of hoods fabricated or ventilation systems installed.

- Discuss challenges you have faced and how you overcame them to showcase your problem-solving abilities.

3. Demonstrate Customer Focus

Share experiences that demonstrate your ability to provide excellent customer service and support.

- Describe how you handled difficult customer inquiries or complaints.

- Highlight your communication skills and ability to build rapport with clients.

4. Prepare for Common Interview Questions

Anticipate questions about your experience, skills, and motivation. Prepare thoughtful answers that align with the job requirements.

Examples:

- “Tell us about your experience in fabricating and installing ventilation hoods.”

- “Describe a time when you had to troubleshoot a complex malfunction in a ventilation system.”

- “How do you stay up-to-date with the latest industry regulations and best practices?”

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Hood Maker role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.