Are you gearing up for a career in Journeyman Sheet Metal Worker? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Journeyman Sheet Metal Worker and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

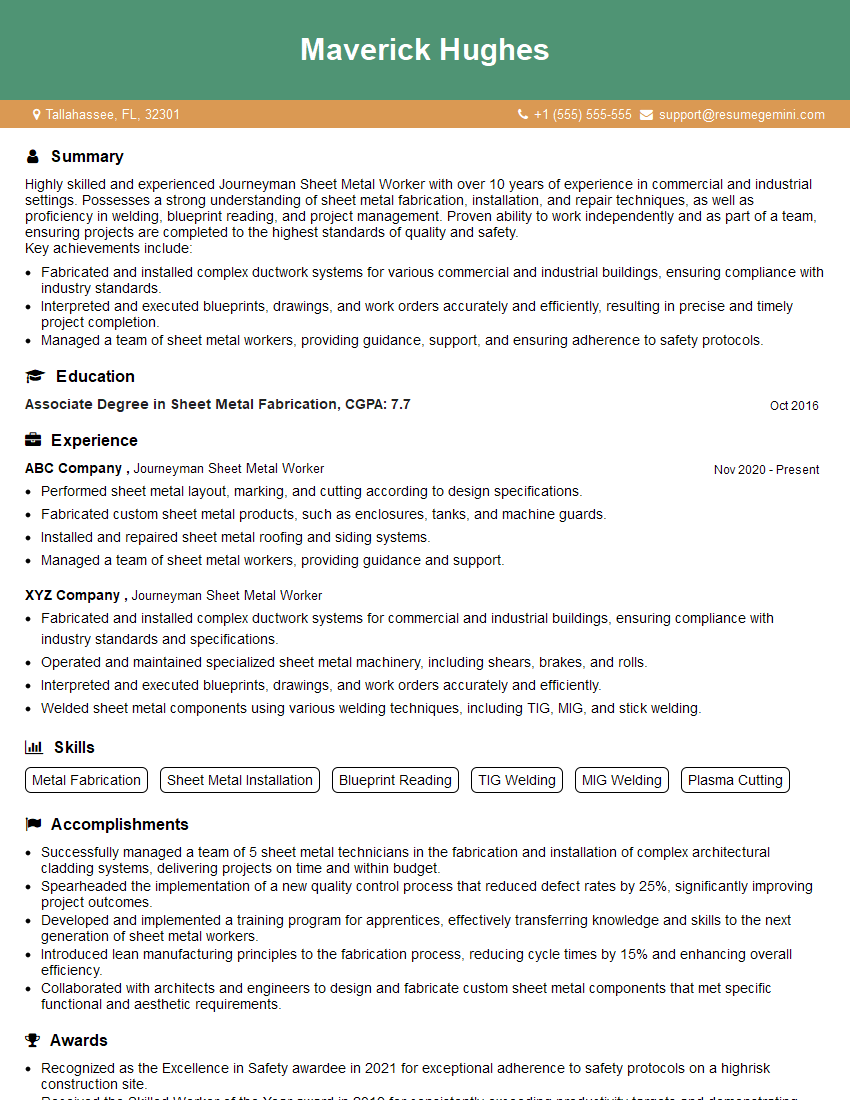

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Journeyman Sheet Metal Worker

1. What are the different types of sheet metal you have worked with and what are their properties?

I have worked with various types of sheet metal, including galvanized steel, stainless steel, aluminum, copper, and brass. Each type of sheet metal has unique properties that make it suitable for different applications.

- Galvanized steel is coated with zinc to protect it from corrosion, making it suitable for outdoor applications.

- Stainless steel is resistant to corrosion and heat, making it ideal for use in food processing and medical equipment.

- Aluminum is lightweight and corrosion-resistant, making it suitable for aircraft and marine applications.

- Copper has high electrical conductivity and is often used in electrical wiring and heat exchangers.

- Brass is a copper alloy with zinc added, making it harder and more durable.

2. What are the different sheet metal fabrication techniques that you are familiar with?

Cutting

- Shear cutting

- Laser cutting

- Waterjet cutting

- Plasma cutting

Forming

- Bending

- Rolling

- Stamping

- Deep drawing

Joining

- Welding

- Soldering

- Brazing

- Mechanical fastening

3. What is the difference between soft and hard soldering?

Soft soldering uses a solder that melts below 450°C, while hard soldering uses a solder that melts above 450°C. Soft soldering is typically used for joining electrical components and small parts, while hard soldering is used for joining larger parts and those that require higher strength.

- Soft solder is easier to use and requires less heat, but it is not as strong as hard solder.

- Hard solder creates a stronger joint, but it requires more heat and can damage sensitive components.

4. What are the safety precautions that must be taken when working with sheet metal?

- Wear appropriate protective gear, including gloves, safety glasses, and a respirator when necessary.

- Use sharp tools and machinery carefully to avoid cuts and lacerations.

- Be aware of pinch points and sharp edges.

- Keep work areas clean and free of debris.

- Follow proper lifting techniques to avoid back injuries.

5. What are the different types of blueprints that you have experience with?

- Architectural blueprints

- Mechanical blueprints

- Electrical blueprints

- HVAC blueprints

- Piping blueprints

6. What is the difference between a brazier and a burnisher?

- A brazier is a tool used to heat metal, while a burnisher is a tool used to smooth and polish metal.

- Braziers are typically used in conjunction with soldering and welding, while burnishers are used in conjunction with finishing and polishing operations.

7. What is your experience with using power tools, such as drills, grinders, and saws?

I have extensive experience using power tools, such as drills, grinders, and saws. I am proficient in using these tools safely and efficiently to perform a variety of tasks, such as cutting, shaping, and assembling sheet metal components.

- I have used drills to create holes in sheet metal, wood, and plastic.

- I have used grinders to smooth and shape sheet metal edges.

- I have used saws to cut sheet metal into various shapes and sizes.

8. What is your experience with working in a team environment?

I have a proven track record of working effectively in a team environment. I am a good communicator and I am always willing to help my teammates. I am also able to take direction from my superiors and I am always willing to learn new things.

- In my previous role, I was part of a team that was responsible for the fabrication and installation of sheet metal components for a large commercial building.

- I was responsible for working with other team members to ensure that the project was completed on time and within budget.

- I also worked with other trades, such as electricians and plumbers, to ensure that the sheet metal components were properly integrated with the other building systems.

9. What is your experience with using computer-aided design (CAD) software?

I have experience using a variety of CAD software programs, including AutoCAD, SolidWorks, and Inventor. I am proficient in using these programs to create 2D and 3D models of sheet metal components. I also have experience using CAD software to generate CNC code for cutting and forming sheet metal.

- In my previous role, I used CAD software to create detailed drawings of sheet metal components for a variety of projects.

- I also used CAD software to generate CNC code for a CNC plasma cutter and a CNC press brake.

10. What are your strengths and weaknesses as a Journeyman Sheet Metal Worker?

Strengths- I am a highly skilled and experienced Journeyman Sheet Metal Worker with a strong understanding of the trade.

- I am proficient in all aspects of sheet metal fabrication, including cutting, forming, and joining.

- I am also familiar with the various types of sheet metal and their properties.

- I am a hard worker and I am always willing to learn new things.

- I am also a good communicator and I am able to work effectively in a team environment.

- I am sometimes too detail-oriented and I can be a perfectionist.

- I can also be impatient at times.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Journeyman Sheet Metal Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Journeyman Sheet Metal Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Journeyman Sheet Metal Worker, you will be primarily responsible for the fabrication and installation of sheet metal components and systems, including roofing, gutters, downspouts, siding, ventilation ducts, and other components.

1. Fabrication

In this role, you will interpret blueprints and specifications to understand the requirements of the project. You will then use a variety of tools and equipment to cut, bend, and shape sheet metal into the desired shapes and sizes. This may involve using hand tools, such as shears, hammers, and punches, as well as power tools, such as drills, saws, and presses. You may also be required to operate welding equipment to join sheet metal components.

- Interpret blueprints and specifications

- Use a variety of tools and equipment to cut, bend, and shape sheet metal

- Operate welding equipment to join sheet metal components

2. Installation

Once the sheet metal components have been fabricated, you will be responsible for installing them in the appropriate locations, including roofs, walls, and other structures. This will involve using specialized tools and equipment to secure the sheet metal components in place and ensure that they are properly sealed and insulated. You may also be required to perform maintenance and repairs on existing sheet metal systems.

- Install sheet metal components in roofs, walls, and other structures

- Use specialized tools and equipment to secure sheet metal components in place

- Perform maintenance and repairs on existing sheet metal systems

3. Safety

As a Journeyman Sheet Metal Worker, you will be required to adhere to strict safety protocols and wear appropriate safety gear when working with sheet metal. This is because working with sheet metal can involve hazards, such as sharp edges, heavy materials, and electrical equipment. You must be aware of these hazards and take appropriate precautions to avoid injury.

- Adhere to strict safety protocols

- Wear appropriate safety gear

- Be aware of hazards and take appropriate precautions to avoid injury

4. Communication

As a Journeyman Sheet Metal Worker, you will need to be able to communicate effectively with colleagues, clients, and other stakeholders. This may involve providing updates on project progress, resolving issues, and answering questions. You may also be required to write reports and documentation.

- Communicate effectively with colleagues, clients, and other stakeholders

- Provide updates on project progress

- Resolve issues

- Answer questions

- Write reports and documentation

Interview Tips

Preparing for an interview can be daunting, but there are steps you can take to increase your chances of success.

1. Research the company and the position

Take some time to learn about the company you’re applying to and the specific position you’re interested in. This will help you understand the company’s culture, values, and goals, and it will also help you tailor your answers to the interviewer’s questions and show that you are genuinely interested in the position.

- Visit the company’s website

- Read articles and news about the company

- Talk to people in your network who work for the company

- Review the job description carefully

2. Practice answering common interview questions

There are a few common interview questions that you’re likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It’s a good idea to practice answering these questions in advance so that you can deliver your answers confidently and clearly.

- Use the STAR method to answer behavioral questions

- Prepare examples of your work that demonstrate your skills and experience

- Be prepared to talk about your strengths and weaknesses

3. Dress professionally and arrive on time

First impressions matter, so it’s important to dress professionally for your interview. You should also arrive on time, or even a few minutes early. This shows that you are respectful of the interviewer’s time and that you are serious about the position.

- Wear a suit or business casual attire

- Make sure your clothes are clean and pressed

- Arrive on time for your interview

4. Be yourself and be enthusiastic

It’s important to be yourself during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Be enthusiastic about the position and the company, and let your personality shine through.

- Be yourself

- Be enthusiastic

- Let your personality shine through

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Journeyman Sheet Metal Worker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.