Are you gearing up for an interview for a Sheet Metal Technician position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Sheet Metal Technician and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

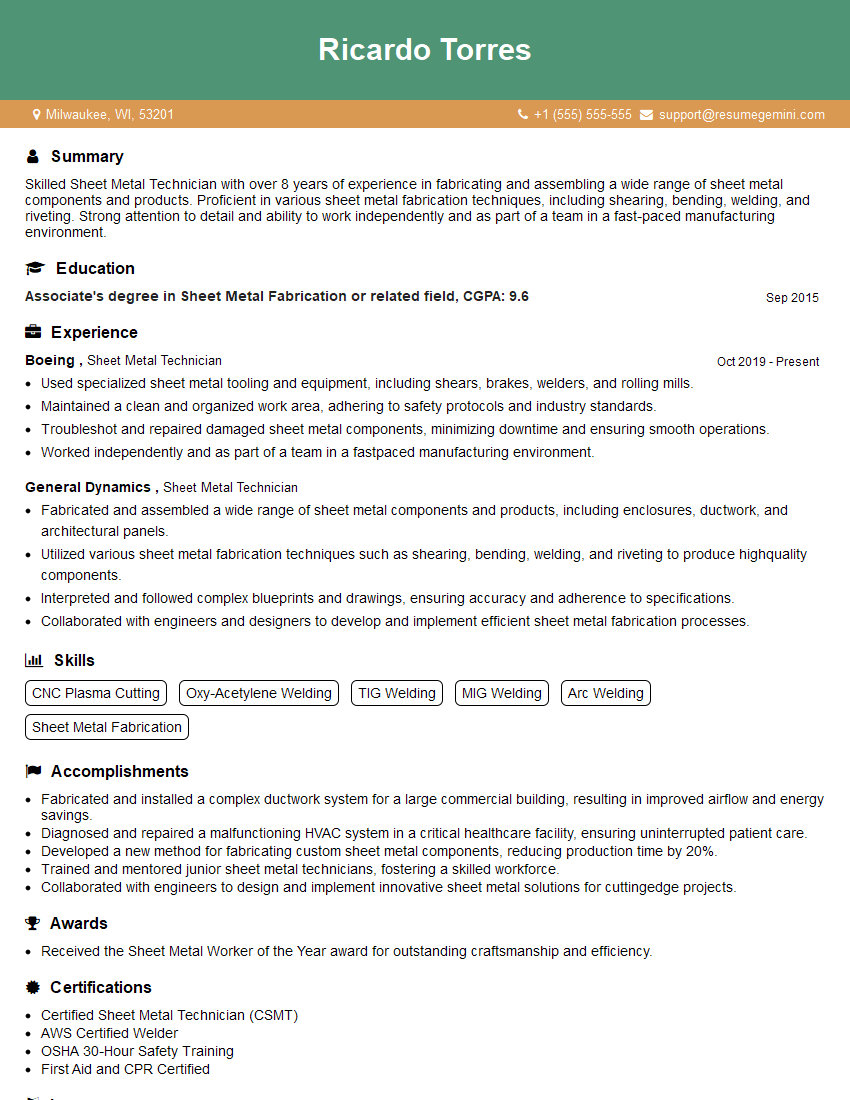

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sheet Metal Technician

1. What are the different types of sheet metal and their applications?

Sheet metal comes in a variety of types, each with its own set of properties and applications. Some of the most common types include:

- Cold-rolled steel: This is the most common type of sheet metal, and it is used in a wide variety of applications, including automotive, appliances, and construction.

- Hot-rolled steel: This type of sheet metal is stronger than cold-rolled steel, but it is also more brittle. It is often used in applications where strength is more important than ductility.

- Galvanized steel: This type of sheet metal is coated with a layer of zinc, which helps to protect it from corrosion. It is often used in outdoor applications, such as roofing and siding.

- Aluminum: This type of sheet metal is lightweight and corrosion-resistant, making it ideal for use in aircraft, marine, and food processing applications.

- Stainless steel: This type of sheet metal is highly resistant to corrosion and heat, making it ideal for use in food processing, chemical processing, and medical applications.

2. What are the different types of sheet metalworking processes?

Cutting

- Shearing

- Punching

- Laser cutting

- Waterjet cutting

Bending

- Press brake forming

- Roll forming

- Hand bending

Joining

- Welding

- Soldering

- Brazing

- Mechanical fastening

3. What are the different types of sheet metal finishes?

- Clear: This type of finish provides no protection for the sheet metal, but it does allow the natural color of the metal to show through.

- Coated: This type of finish provides protection for the sheet metal from corrosion and wear. Coatings can be applied in a variety of colors and textures.

- Painted: This type of finish provides protection for the sheet metal from corrosion and wear, and it also allows for a wide range of colors and designs.

4. What are the safety precautions that must be taken when working with sheet metal?

- Wear appropriate safety gear, including gloves, safety glasses, and a hard hat.

- Be aware of sharp edges and moving parts.

- Use proper lifting techniques.

- Keep the work area clean and free of debris.

- Follow all safety procedures and regulations.

5. What are the key skills and qualities of a successful sheet metal technician?

- Technical skills: Sheet metal technicians must have a strong understanding of sheet metalworking processes, including cutting, bending, joining, and finishing.

- Attention to detail: Sheet metal technicians must be able to work with precision and accuracy.

- Problem-solving skills: Sheet metal technicians must be able to troubleshoot problems and find solutions.

- Communication skills: Sheet metal technicians must be able to communicate effectively with other team members and customers.

- Physical stamina: Sheet metal technicians must be able to perform physically demanding tasks, such as lifting and moving heavy objects.

6. What are the different types of welding processes used in sheet metal fabrication?

- MIG welding: This is a type of arc welding that uses a consumable wire electrode and a shielding gas to create a weld.

- TIG welding: This is a type of arc welding that uses a non-consumable tungsten electrode and a shielding gas to create a weld.

- Spot welding: This is a type of resistance welding that uses two electrodes to apply pressure and heat to a localized area of the sheet metal, creating a weld.

7. What are the different types of bending processes used in sheet metal fabrication?

- Press brake forming: This is a type of bending process that uses a press brake machine to bend sheet metal to a specific angle.

- Roll forming: This is a type of bending process that uses a series of rollers to gradually bend sheet metal into a desired shape.

- Hand bending: This is a type of bending process that uses hand tools, such as a hammer and anvil, to bend sheet metal.

8. What are the different types of joining processes used in sheet metal fabrication?

- Welding: This is a process that uses heat to join two pieces of sheet metal.

- Soldering: This is a process that uses a low-melting-point metal alloy to join two pieces of sheet metal.

- Brazing: This is a process that uses a high-melting-point metal alloy to join two pieces of sheet metal.

- Mechanical fastening: This is a process that uses mechanical fasteners, such as bolts, nuts, and screws, to join two pieces of sheet metal.

9. What are the different types of sheet metal finishes used in sheet metal fabrication?

- Clear: This type of finish provides no protection for the sheet metal, but it does allow the natural color of the metal to show through.

- Coated: This type of finish provides protection for the sheet metal from corrosion and wear. Coatings can be applied in a variety of colors and textures.

- Painted: This type of finish provides protection for the sheet metal from corrosion and wear, and it also allows for a wide range of colors and designs.

10. What are the different types of sheet metal forming processes used in sheet metal fabrication?

- Stretching: This is a forming process that uses tension to stretch sheet metal into a desired shape.

- Drawing: This is a forming process that uses a punch and die to draw sheet metal into a desired shape.

- Spinning: This is a forming process that uses a spinning lathe to spin sheet metal into a desired shape.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sheet Metal Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sheet Metal Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Sheet Metal Technicians are responsible for fabricating, assembling, and installing sheet metal products and components.

1. Fabrication

Fabricating sheet metal components involves cutting, bending, and shaping sheet metal using specialized tools and equipment

- Read and interpret blueprints and specifications.

- Operate shearing, bending, rolling, and welding equipment.

2. Assembly

Assembling sheet metal components into finished products requires precision and attention to detail.

- Join sheet metal components using rivets, screws, or welding.

- Inspect and test assembled products to ensure quality.

3. Installation

Installing sheet metal products and components in various settings demands knowledge of construction practices.

- Install ductwork, roofing, and siding.

- Repair and maintain sheet metal structures and components.

4. Troubleshooting

Troubleshooting and resolving issues related to sheet metal products and components requires problem-solving skills.

- Diagnose and repair problems with ductwork, roofing, and siding.

- Identify and resolve issues with sheet metal fabrication and assembly.

Interview Tips

Preparing for a Sheet Metal Technician interview involves researching the company, practicing your answers, and presenting yourself professionally. Here are some tips to help you ace the interview.

1. Research the Company and Position

Researching the company and the specific job responsibilities will give you a better understanding of the expectations. This will help you tailor your answers and demonstrate your knowledge of the industry.

- Visit the company website to learn about its products or services, culture, and career opportunities.

- Read online reviews and articles to gain insights into the company’s reputation and work environment.

2. Practice Your Answers

Practicing answering potential interview questions will boost your confidence and help you articulate your skills and experience effectively. Prepare responses to questions about your technical abilities, problem-solving skills, and work experience.

- Write down potential questions and craft well-structured answers that highlight your strengths and qualifications.

- Consider using the STAR method (Situation, Task, Action, Result) to present your past experiences in a clear and organized way.

3. Showcase Your Skills and Experience

During the interview, emphasize your technical skills, such as your proficiency in sheet metal fabrication, assembly, and installation. Highlight your experience working with different sheet metal materials and tools.

- Provide specific examples of projects you have worked on, quantifying your accomplishments whenever possible.

- Be prepared to discuss your knowledge of industry standards, codes, and safety regulations.

4. Professionalism and Communication

First impressions matter, so dress professionally and arrive on time for your interview. Be polite and respectful to everyone you encounter, including the receptionist and interviewers.

- Maintain eye contact, speak clearly, and actively listen to the interviewer’s questions.

- Prepare questions of your own to ask at the end of the interview, as this demonstrates your interest and engagement.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Sheet Metal Technician, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Sheet Metal Technician positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.